Resistive touch screens

| Image | View the product | No. Manufacturer | ||||

|---|---|---|---|---|---|---|

| picture_as_pdf |

|

A D METRO | ULTRA Resistive touch screen | SEE IT | -- | On Order |

| picture_as_pdf |

|

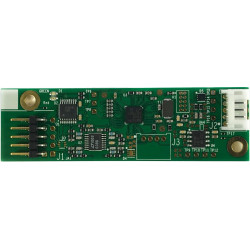

A D METRO | Resistive Touch Screen Controller (2-point) | SEE IT | -- | On Order |

Resistive touch screens are among the most proven and versatile touch technologies, widely used in HMI (Human-Machine Interface) systems, industrial automation, medical devices, military systems, and point-of-sale terminals. Their popularity stems from their reliability, durability, and ability to operate in harsh environmental conditions.

The resistive technology is based on a simple yet effective mechanism – detection of touch through pressure on conductive layers. When the user presses the screen surface with a finger, stylus, or while wearing protective gloves, two conductive layers come into contact, sending a signal to the controller. Thanks to this, resistive screens work independently of skin conductivity, and their operation does not require special tools or sensitive coatings.

Why use resistive touch screens?

- Versatile operation – works with a finger, stylus, or protective gloves.

- Resistance to harsh conditions – dust, moisture, oils, chemicals, or scratches do not interfere with the screen’s performance.

- High precision and touch repeatability – the screens provide millions of accurate touches without loss of functionality.

- Application versatility – from heavy industry and production machinery, through medical devices, to kiosks and POS terminals.

Compared to capacitive (PCAP) screens, resistive technology focuses on durability and resilience in environments where other screens could fail. This makes resistive touch screens a top choice where reliability, glove operation, and resistance to physical and chemical external factors are essential.

Resistive touch screens operate through physical pressure that causes contact between two conductive layers inside the screen. These layers are separated by a thin air gap or spacers, and upon contact, an electrical signal is sent to the controller, which registers the coordinates of the touch point.

Standard versions: 4-, 5-, and 8-wire

Resistive screens are available in various conduction variants that differ in voltage measurement methods and durability:

- 4-wire – the simplest solution, where touch measurement occurs through two conductive layers. Offers basic precision and is used in moderately intensive applications.

- 5-wire – the conductive layer placed on the bottom glass increases the screen’s durability. Therefore, 5-wire screens withstand a significantly greater number of touches and are resistant to mechanical damage.

- 8-wire – an improved version of 4-wire, enhancing touch accuracy and wear resistance in high-use environments.

ULTRA Resistive Technology

Advanced ULTRA Resistive touch screens are designed for extreme working conditions. Thanks to the use of borosilicate tempered glass and reinforced polyester layers, ULTRA screens offer:

- Increased durability and resistance to shocks and vibrations, making them ideal for heavy industry and military applications.

- Resistance to temperatures from -35°C to +70°C as well as to humidity, dust, dirt, and oils.

- Operation with gloves or stylus, increasing versatility in tough environments.

- Protection against electromagnetic (EMI/RFI) interference, ensuring reliable operation near machines generating strong electromagnetic fields.

The ULTRA Resistive technology also allows screen integration in underwater and outdoor devices, where standard resistive screens might fail.

Advantages and features of resistive screens

Resistive touch screens stand out for their reliability and durability, making them ideal for demanding working environments. Their construction, based on two conductive layers reacting to pressure, allows for precise operation regardless of the conditions in which they are used.

Resistance to dust, moisture, and contamination

Resistive screens are exceptionally resistant to external factors. Dust, dirt, moisture, oils, or chemical contaminants do not affect panel functionality. This makes them reliable in industrial, military, or laboratory environments where standard capacitive screens might fail.

Mechanical and chemical resistance

Thanks to a robust construction and durable materials, resistive screens are resistant to shocks, vibrations, and mechanical impacts. Additionally, some models offer resistance to contact with chemicals, making them suitable for laboratories, production plants, and the medical sector.

High precision and longevity

Resistive technology ensures accurate and stable touch detection even with intensive use. The screens can withstand millions of touches without losing accuracy, giving them a much longer lifespan than many other touch technologies available on the market.

Stable touch detection in tough conditions

Resistive screens maintain stable touch readings across a wide temperature range and exposure to various external factors. Their operation is unaffected by water, dust, or humidity changes, making them ideal for industrial, military, or outdoor applications.

Thanks to these properties, resistive touch screens are a universal, durable, and reliable solution that performs well in harsh working environments and applications requiring the highest precision and resistance to external factors.

ULTRA Resistive Technology

ULTRA Resistive technology is an advanced resistive touch screen solution designed for demanding industrial, military, and outdoor environments. It provides exceptional durability, reliability, and resistance to external factors that could limit the functionality of standard models.

Extended ITO layer lifespan

In resistive screens, the conductive ITO (Indium Tin Oxide) layer is a critical element responsible for precise touch detection. ULTRA Resistive technology uses tempered glass substrates and reinforced laminates that protect the ITO layer from cracking and wear. The result is up to ten times longer lifespan while maintaining full accuracy throughout its use.

Resistance to extreme temperatures

ULTRA Resistive screens operate across a wide temperature range – from -35°C to +70°C in operation and from -40°C to +85°C in storage. This makes them suitable for cold climates, hot production halls, military vehicles, or outdoor systems where standard screens might fail.

Resistance to shocks, vibrations, and EMI/RFI interference

The ULTRA Resistive construction provides resistance to shocks, vibrations, and heavy mechanical use, which is especially important in heavy industry and military applications. Additionally, this technology guarantees protection against electromagnetic and radio interference (EMI/RFI) as well as resistance to electromagnetic pulses (EMP). This ensures stable operation even in difficult environments without erroneous touch readings.

ULTRA Resistive technology combines longevity, extreme condition resistance, and reliability, making these screens ideal for demanding industrial, military, and outdoor applications.

Applications of ULTRA Resistive touch screens

Resistive touch screens, including advanced ULTRA Resistive versions, are widely used in industries where reliability, environmental resistance, and touch precision are critical. Their versatility makes them suitable for both industrial and commercial environments requiring durability and stable performance.

Heavy industry and manufacturing

In manufacturing plants and heavy industry, ULTRA Resistive touch screens are indispensable due to their resistance to dust, moisture, oils, vibrations, and high temperatures. They enable precise operation of machines, control panels, and automation devices, even under heavy use and in restricted spaces.

Military and defense applications

ULTRA Resistive technology is ideal for military and defense applications. These screens are resistant to electromagnetic interference (EMI/RFI/EMP), extreme temperatures, shocks, and vibrations, and can be operated with a finger, glove, or stylus. They perform reliably in armored vehicles, field command terminals, navigation systems, and soldier-mounted devices.

Automation and HMI systems

ULTRA Resistive screens are commonly used in HMI (Human-Machine Interface) systems and industrial automation. Their precise touch detection and environmental resistance allow operators to react quickly to process changes, monitor machine parameters, and control devices effectively in challenging conditions.

Self-service kiosks, POS terminals, medical devices

Not only industry and the military benefit from resistive touch screens. Their resistance to dirt, dust, and moisture also makes them suitable for self-service kiosks, POS terminals, ATMs, medical devices, and hospital control panels. Stable touch performance, glove compatibility, and high durability ensure reliability in high-traffic public areas.

ULTRA Resistive touch screens are therefore a universal, durable, and versatile solution, perfectly suited for industrial, military, and commercial environments, providing reliable touch operation even in the most demanding conditions.

Selecting the right resistive screen

Choosing a resistive touch screen should be preceded by an analysis of the working environment, application type, and user requirements regarding durability and functionality. With a wide range of available solutions – from standard 4-, 5-, and 8-wire versions to advanced ULTRA Resistive models – it is possible to perfectly match the screen to specific operational needs.

Selection criteria

1. Durability and longevity – consider the number of touch cycles, resistance to shocks, vibrations, and mechanical stress. In high-usage environments, ULTRA Resistive screens are recommended, offering up to ten times longer ITO layer lifespan than standard versions.

2. Environmental resistance – dust, moisture, oils, chemicals, and extreme temperatures significantly affect reliability. ULTRA Resistive screens provide full resistance to industrial and military conditions, while standard versions are better suited for controlled or indoor environments.

3. Operation method – determine whether the screen will be operated by finger, glove, or stylus. Standard resistive screens support most touch tools, while ULTRA Resistive ensures full functionality in the most demanding scenarios.

4. Size and compatibility – selecting the proper screen size and version (4-, 5-, or 8-wire) affects touch accuracy and integration with control systems.

Standard 4-, 5-, and 8-wire versions

- 4-wire – a simple, cost-effective solution with basic durability, suitable for office and light-use applications.

- 5-wire – enhanced resistance and durability thanks to the conductive layer placed on the glass surface. Ideal for medium-intensity industrial use.

- 8-wire – an improved 4-wire version offering better resistance to heavy use and higher touch accuracy.

ULTRA Resistive

ULTRA Resistive screens are a premium solution designed for operation in extreme conditions. They offer:

- Extended ITO layer lifespan, ensuring stable touch readings through millions of touch cycles.

- Resistance to shocks, vibrations, and EMI/RFI interference, making them ideal for heavy industry and military applications.

- Extreme operating and storage temperatures, enabling use in environments from -35°C to +70°C.

With a variety of options, choosing the right resistive screen ensures not only reliable and precise touch operation but also optimal device adaptation to specific working conditions – key in industrial, military, and commercial applications.

Summary and recommendations

Resistive touch screens are a proven, durable, and reliable solution that performs excellently in demanding industrial, military, medical, and automation environments. Their key advantage is the ability to operate with a finger, glove, or stylus, ensuring full functionality even under challenging conditions. Thanks to resistance to dust, moisture, chemicals, and mechanical damage, resistive screens guarantee long-lasting and precise performance regardless of usage intensity.

Why choose resistive screens

- Versatility and universality – can be operated with various touch tools.

- Durability and reliability – resistant to industrial conditions including shocks, vibrations, extreme temperatures, and electromagnetic interference.

- Longevity – ULTRA Resistive screens offer extended ITO layer lifespan, ensuring stable readings through millions of touch cycles.

- Environmental resistance – dust, moisture, dirt, oils, and chemicals do not affect screen functionality.

Resistive screens combine functionality, durability, and resistance to extreme conditions, making them an ideal choice for users seeking dependable touch solutions. By choosing the right version – standard or ULTRA Resistive – the screen can be perfectly adapted to the specific working environment, ensuring stability, precision, and top-level user comfort.