Category

Photos are for informational purposes only. View product specification

please use latin characters

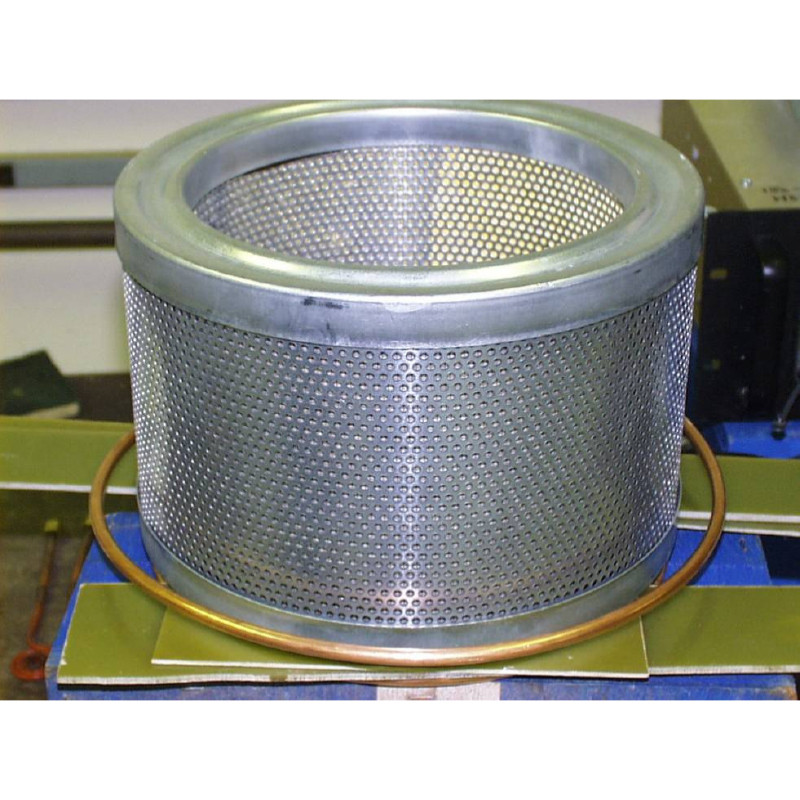

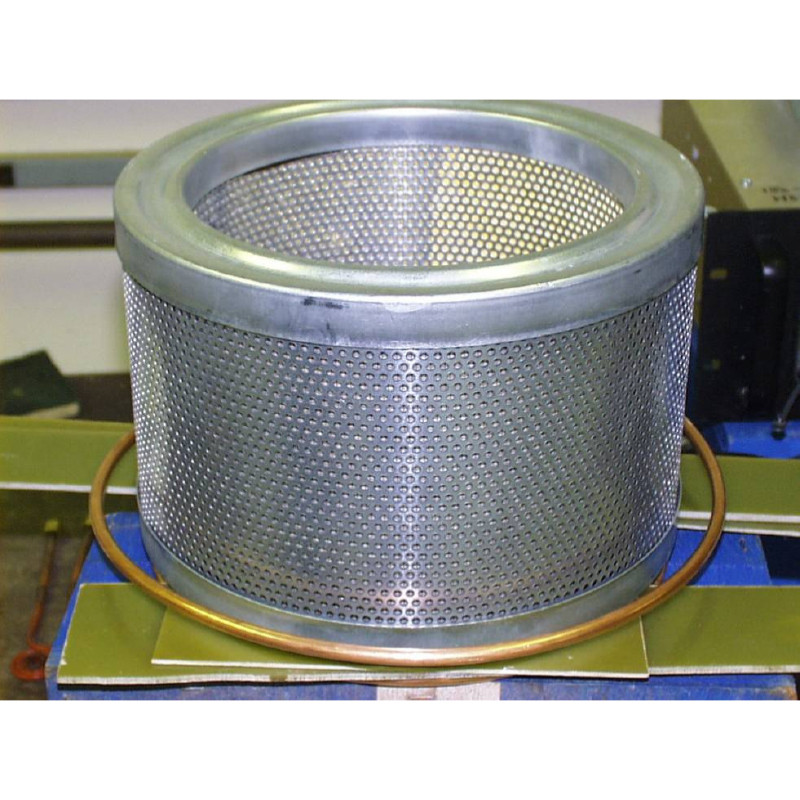

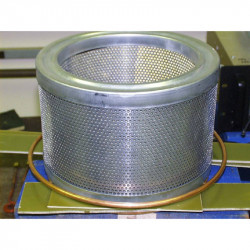

Objective: To cure adhesive in aluminum filter ends.

Frequency: 277 kHz

Material: Aluminum filter, steel end caps & plastisol adhesive

Temperature: 200 °F (94 °C)

A four turn helical coil is used to cure the plastisol adhesive. One filter end cap is filled with adhesive, attached to the filter and heated 90 seconds to cure the adhesive. The filter assembly is then flipped; the second end cap is filled with adhesive and applied to the filter. Heat is applied to that end cap for 90 seconds to cure the adhesive. A second coil is recommended to heat 2 parts at once which would reduce the heat time to 45 seconds per part. The heat time can be further reduced by increasing the number of power supplies and coils.

Are you interested in this product? Do you need additional information or individual pricing?

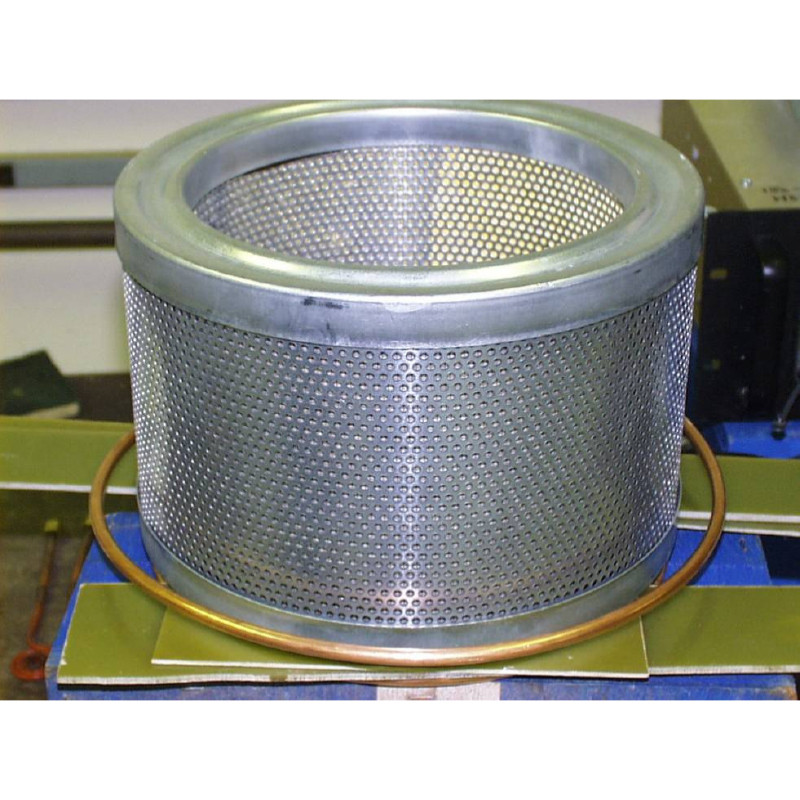

Objective: To cure adhesive in aluminum filter ends.

Frequency: 277 kHz

Material: Aluminum filter, steel end caps & plastisol adhesive

Temperature: 200 °F (94 °C)

A four turn helical coil is used to cure the plastisol adhesive. One filter end cap is filled with adhesive, attached to the filter and heated 90 seconds to cure the adhesive. The filter assembly is then flipped; the second end cap is filled with adhesive and applied to the filter. Heat is applied to that end cap for 90 seconds to cure the adhesive. A second coil is recommended to heat 2 parts at once which would reduce the heat time to 45 seconds per part. The heat time can be further reduced by increasing the number of power supplies and coils.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent