Category

Photos are for informational purposes only. View product specification

please use latin characters

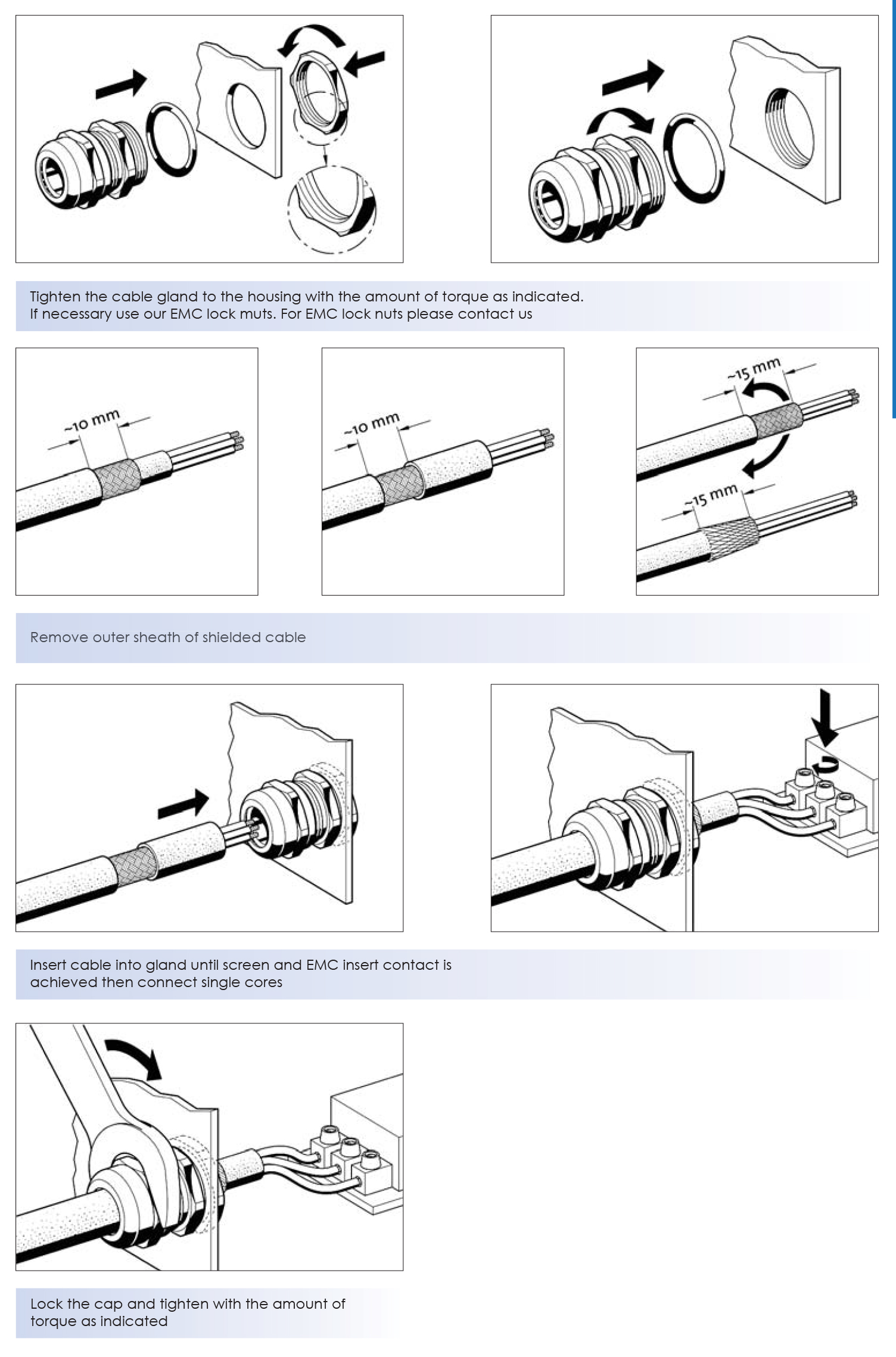

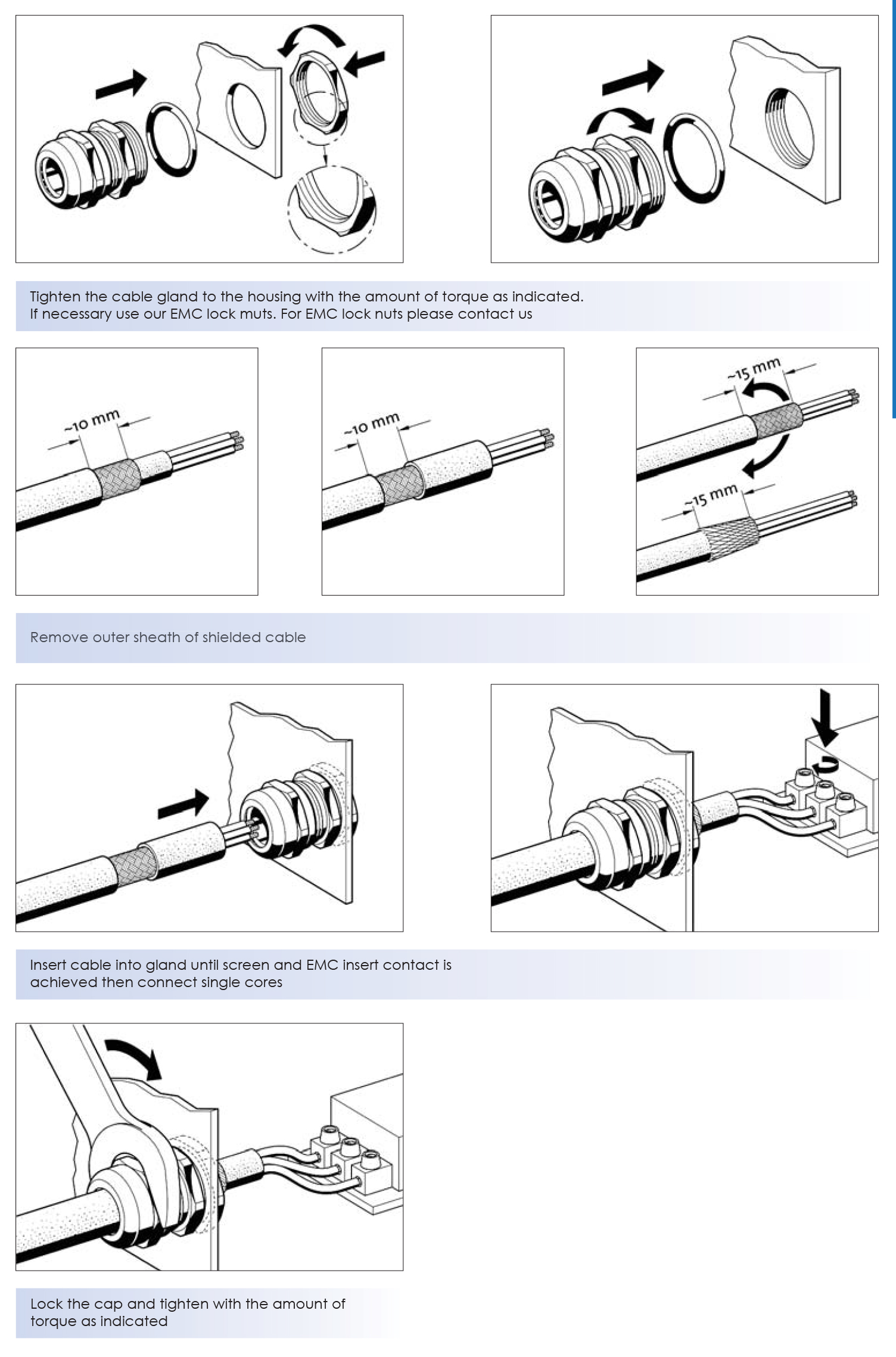

The new generation of Bimed’s EMC and derivation gland shows significant advantages compared to other existing cable glands. The patented contact system inside the gland allows all degrees of freedom which are neccessary to install a cable easily; the cable can be pulled forward and backward inside the gland without damaging the cable shielding. This is realized by specially designed contact elements. This feature is most advantageous when connectorizing the single cores of the cable.

Also the cable can easily be rotated inside the gland without damaging the cable shielding – most important when installing the gland at an industrial connector. The unique mechanism of the integrated contact system therefore show the following features:

For small cable diameters in the lower clamping range of the gland the contact system won’t touch the cable braiding during the installation process at all. For bigger cable diameters in the upper clamping range of the gland, the contact system will rotate freely inside the gland together with the cable itself. Only when tightening the cap the contact element will be fixed and will be pressed against the cable shielding to ensure a low resistance electrical contact between gland and cable braiding. Simultaneously IP68 protection class and cable anchorage according to the EN 62444 is achieved.

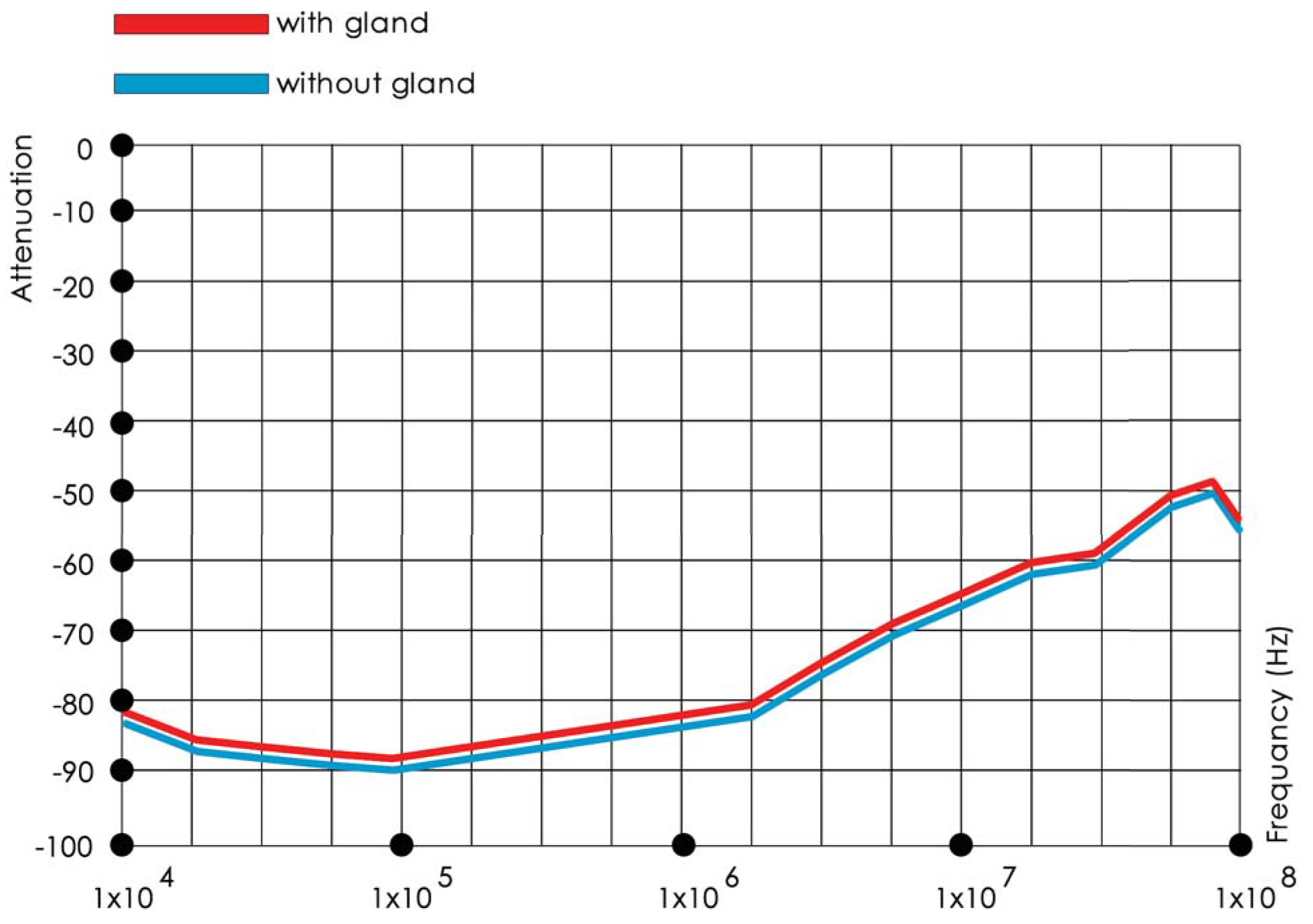

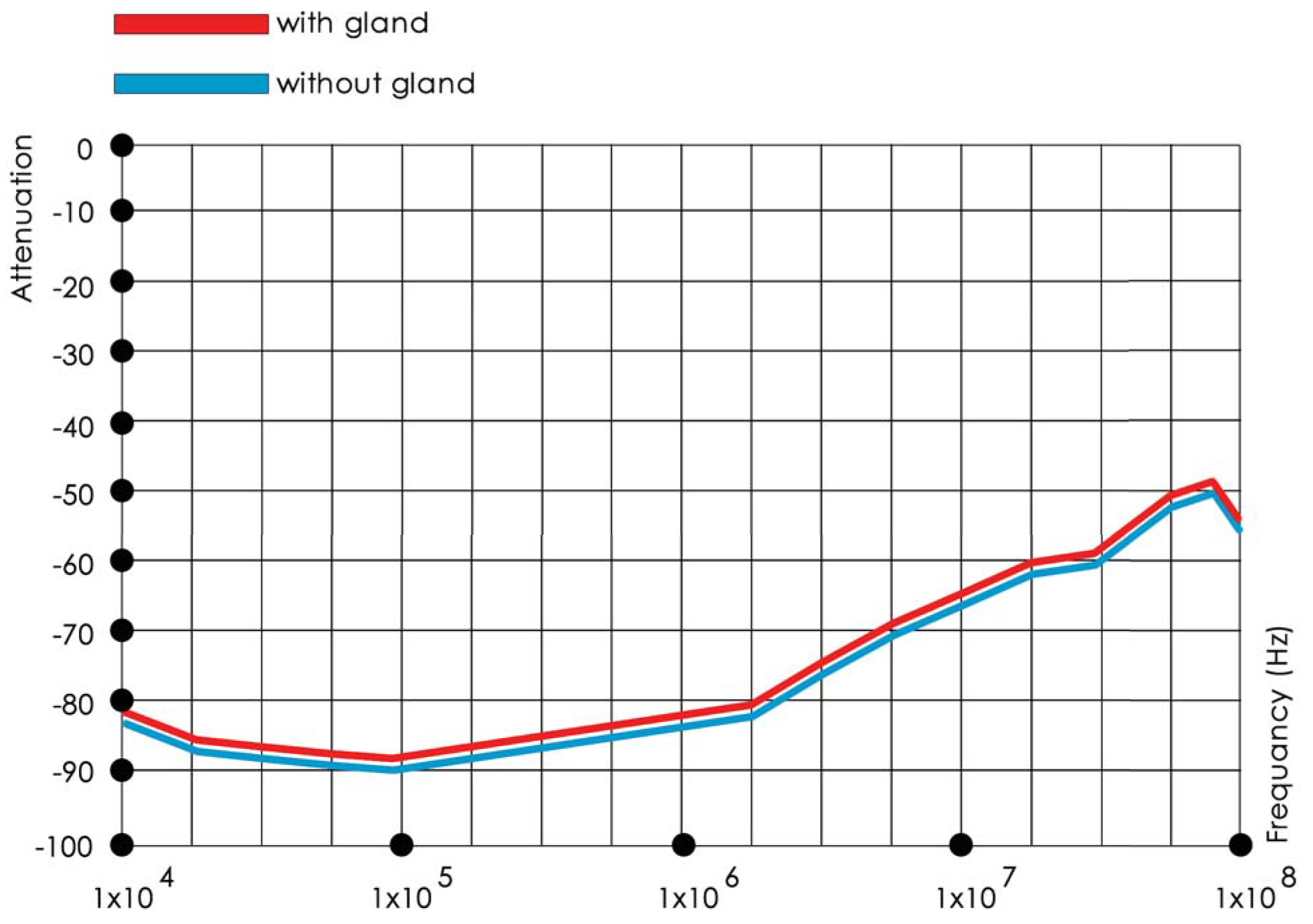

This straight forward application and convenient installation of the gland saves a lot of time and therefore a lot of money.Shielding and derivation tests performed with this gland show exceptional values. So this EMC and derivation gland from Bimed will be used wherever an outstanding performance is needed. Simple application, fast installation together with the patented contact system makes Bimed’s gland unique among the cable glands.

|

|

| Material | Body | Brass, nickel plated | |

|---|---|---|---|

| Cap | Brass, nickel plated | ||

| Seal | CR (chloroprene rubber) | ||

| Clamping insert | PA 6 (polyamide 6) | ||

| Contact spring | Special copper alloy | ||

| O-ring | NBR | ||

| Protection class | IP68 - 5 Bar, 30 min | ||

| Flammability | UL94 V-2 | ||

| Operating temperature | Permanent | Intermittent | |

| -20°C ÷ +100°C | -40°C ÷ +150°C | ||

| Thread type |

|

||

| Cable type | Non armoured, shielded | ||

| Accessories |

|

||

| Remarks |

|

||

| Certificate number | Standards | |

|---|---|---|

|

E199260 | Acc. to UL514 |

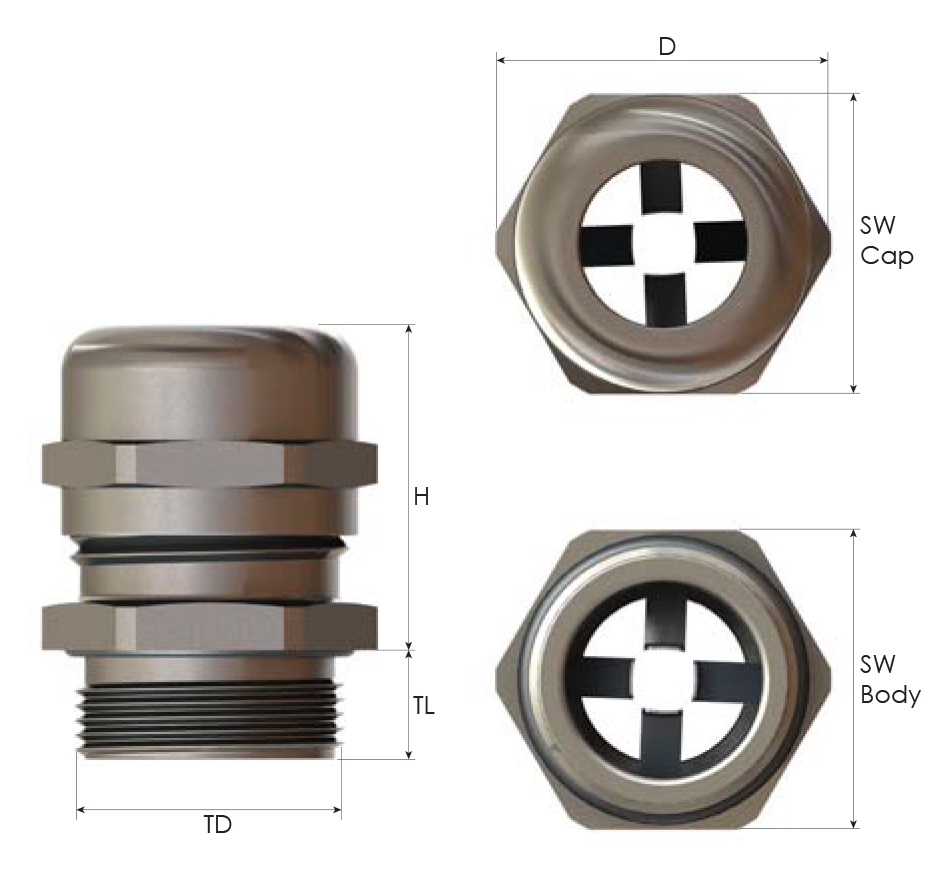

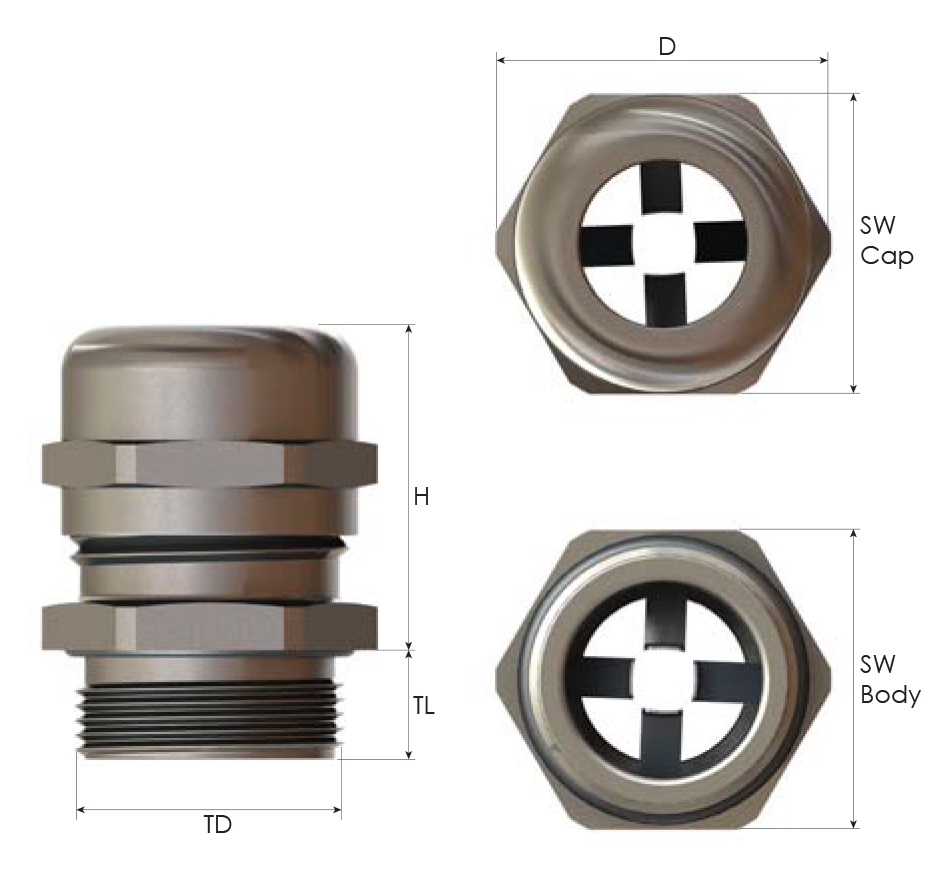

| Size | Clamping range ∅ min - max [mm] | Shield diameter ∅ min - max [mm] | Thread lenght TL [mm] | Thread ∅ TD [mm] | Spanner width | Outer ∅ D [mm] | Max. height H [mm] | Part number | Packing unit | |

|---|---|---|---|---|---|---|---|---|---|---|

| SW Cap [mm] | SW Body [mm] | |||||||||

| M12x1,5 | 3,0 - 6,5 | 2,5 | 6,0 | 12,0 | 14 | 14 | 15,5 | 22,0 | BMEM-ES | 50 |

| M16x1,5 | 5,0 - 10,0 | 4,0 | 7,0 | 16,0 | 20 | 20 | 22,0 | 29,0 | BMEM-E1 | 50 |

| M20x1,5 | 6,0 - 12,0 | 5,0 | 8,0 | 20,0 | 22 | 22 | 24,5 | 27,5 | BMEM-E2 | 50 |

| M25x1,5 | 11,0 - 17,0 | 9,5 | 8,0 | 25,0 | 27 | 27 | 30,0 | 30,7 | BMEM-E3 | 25 |

| M32x1,5 | 15,0 - 21,0 | 13,5 | 8,0 | 32,0 | 34 | 34 | 37,0 | 38,0 | BMEM-E4 | 25 |

| M40x1,5 | 19,0 - 28,0 | 17,0 | 9,0 | 40,0 | 43 | 43 | 48,5 | 43,0 | BMEM-E5 | 20 |

| M50x1,5 | 27,0 - 38,0 | 25,0 | 9,0 | 50,0 | 58 | 58 | 64,0 | 54,5 | BMEM-E6 | 12 |

| M63x1,5 | 34,0 - 44,0 | 31,0 | 14,0 | 63,0 | 64 | 68 | 75,0 | 57,0 | BMEM-E7 | 12 |

Are you interested in this product? Do you need additional information or individual pricing?

The new generation of Bimed’s EMC and derivation gland shows significant advantages compared to other existing cable glands. The patented contact system inside the gland allows all degrees of freedom which are neccessary to install a cable easily; the cable can be pulled forward and backward inside the gland without damaging the cable shielding. This is realized by specially designed contact elements. This feature is most advantageous when connectorizing the single cores of the cable.

Also the cable can easily be rotated inside the gland without damaging the cable shielding – most important when installing the gland at an industrial connector. The unique mechanism of the integrated contact system therefore show the following features:

For small cable diameters in the lower clamping range of the gland the contact system won’t touch the cable braiding during the installation process at all. For bigger cable diameters in the upper clamping range of the gland, the contact system will rotate freely inside the gland together with the cable itself. Only when tightening the cap the contact element will be fixed and will be pressed against the cable shielding to ensure a low resistance electrical contact between gland and cable braiding. Simultaneously IP68 protection class and cable anchorage according to the EN 62444 is achieved.

This straight forward application and convenient installation of the gland saves a lot of time and therefore a lot of money.Shielding and derivation tests performed with this gland show exceptional values. So this EMC and derivation gland from Bimed will be used wherever an outstanding performance is needed. Simple application, fast installation together with the patented contact system makes Bimed’s gland unique among the cable glands.

|

|

| Material | Body | Brass, nickel plated | |

|---|---|---|---|

| Cap | Brass, nickel plated | ||

| Seal | CR (chloroprene rubber) | ||

| Clamping insert | PA 6 (polyamide 6) | ||

| Contact spring | Special copper alloy | ||

| O-ring | NBR | ||

| Protection class | IP68 - 5 Bar, 30 min | ||

| Flammability | UL94 V-2 | ||

| Operating temperature | Permanent | Intermittent | |

| -20°C ÷ +100°C | -40°C ÷ +150°C | ||

| Thread type |

|

||

| Cable type | Non armoured, shielded | ||

| Accessories |

|

||

| Remarks |

|

||

| Certificate number | Standards | |

|---|---|---|

|

E199260 | Acc. to UL514 |

| Size | Clamping range ∅ min - max [mm] | Shield diameter ∅ min - max [mm] | Thread lenght TL [mm] | Thread ∅ TD [mm] | Spanner width | Outer ∅ D [mm] | Max. height H [mm] | Part number | Packing unit | |

|---|---|---|---|---|---|---|---|---|---|---|

| SW Cap [mm] | SW Body [mm] | |||||||||

| M12x1,5 | 3,0 - 6,5 | 2,5 | 6,0 | 12,0 | 14 | 14 | 15,5 | 22,0 | BMEM-ES | 50 |

| M16x1,5 | 5,0 - 10,0 | 4,0 | 7,0 | 16,0 | 20 | 20 | 22,0 | 29,0 | BMEM-E1 | 50 |

| M20x1,5 | 6,0 - 12,0 | 5,0 | 8,0 | 20,0 | 22 | 22 | 24,5 | 27,5 | BMEM-E2 | 50 |

| M25x1,5 | 11,0 - 17,0 | 9,5 | 8,0 | 25,0 | 27 | 27 | 30,0 | 30,7 | BMEM-E3 | 25 |

| M32x1,5 | 15,0 - 21,0 | 13,5 | 8,0 | 32,0 | 34 | 34 | 37,0 | 38,0 | BMEM-E4 | 25 |

| M40x1,5 | 19,0 - 28,0 | 17,0 | 9,0 | 40,0 | 43 | 43 | 48,5 | 43,0 | BMEM-E5 | 20 |

| M50x1,5 | 27,0 - 38,0 | 25,0 | 9,0 | 50,0 | 58 | 58 | 64,0 | 54,5 | BMEM-E6 | 12 |

| M63x1,5 | 34,0 - 44,0 | 31,0 | 14,0 | 63,0 | 64 | 68 | 75,0 | 57,0 | BMEM-E7 | 12 |

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent