Category

Photos are for informational purposes only. View product specification

please use latin characters

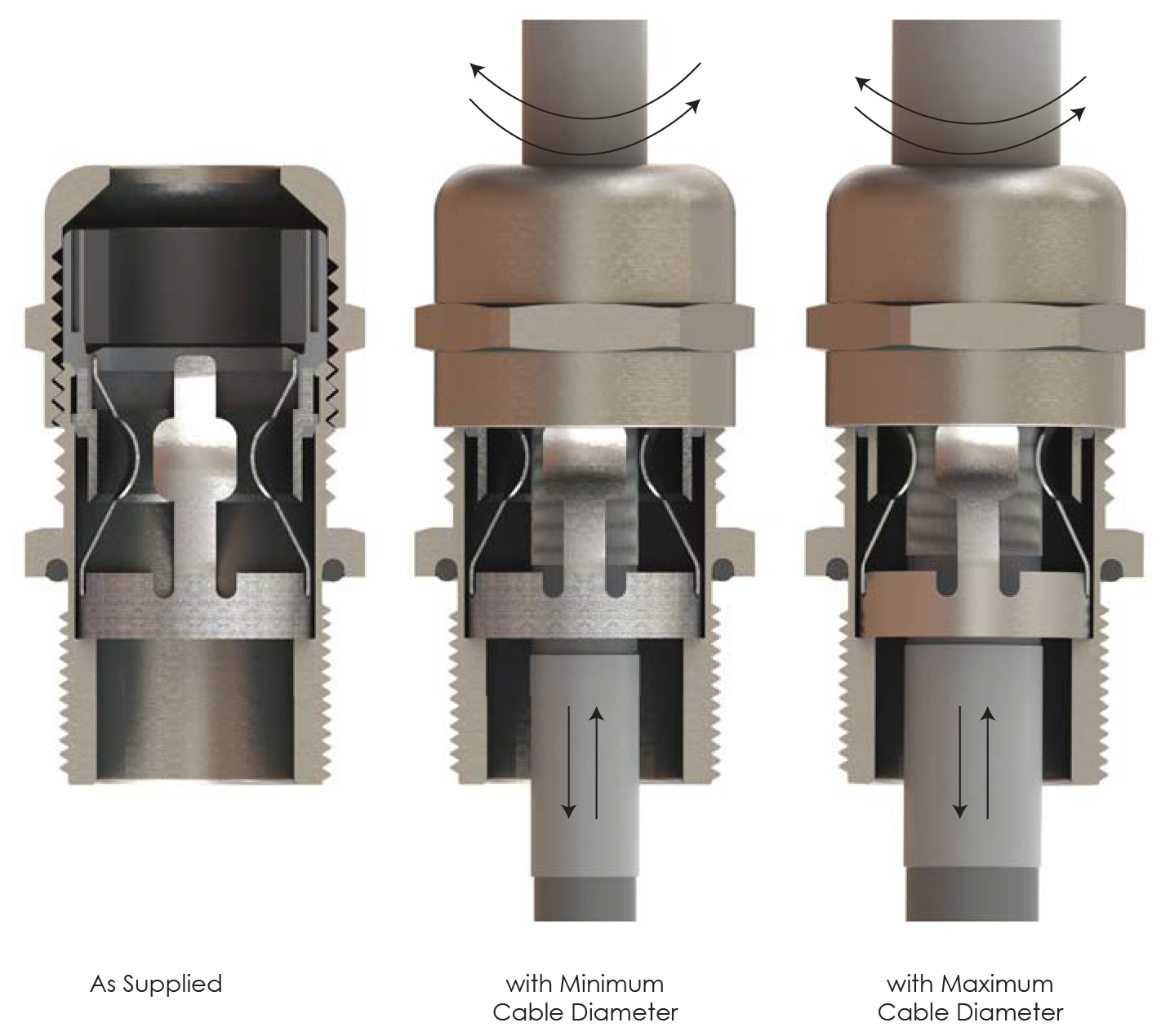

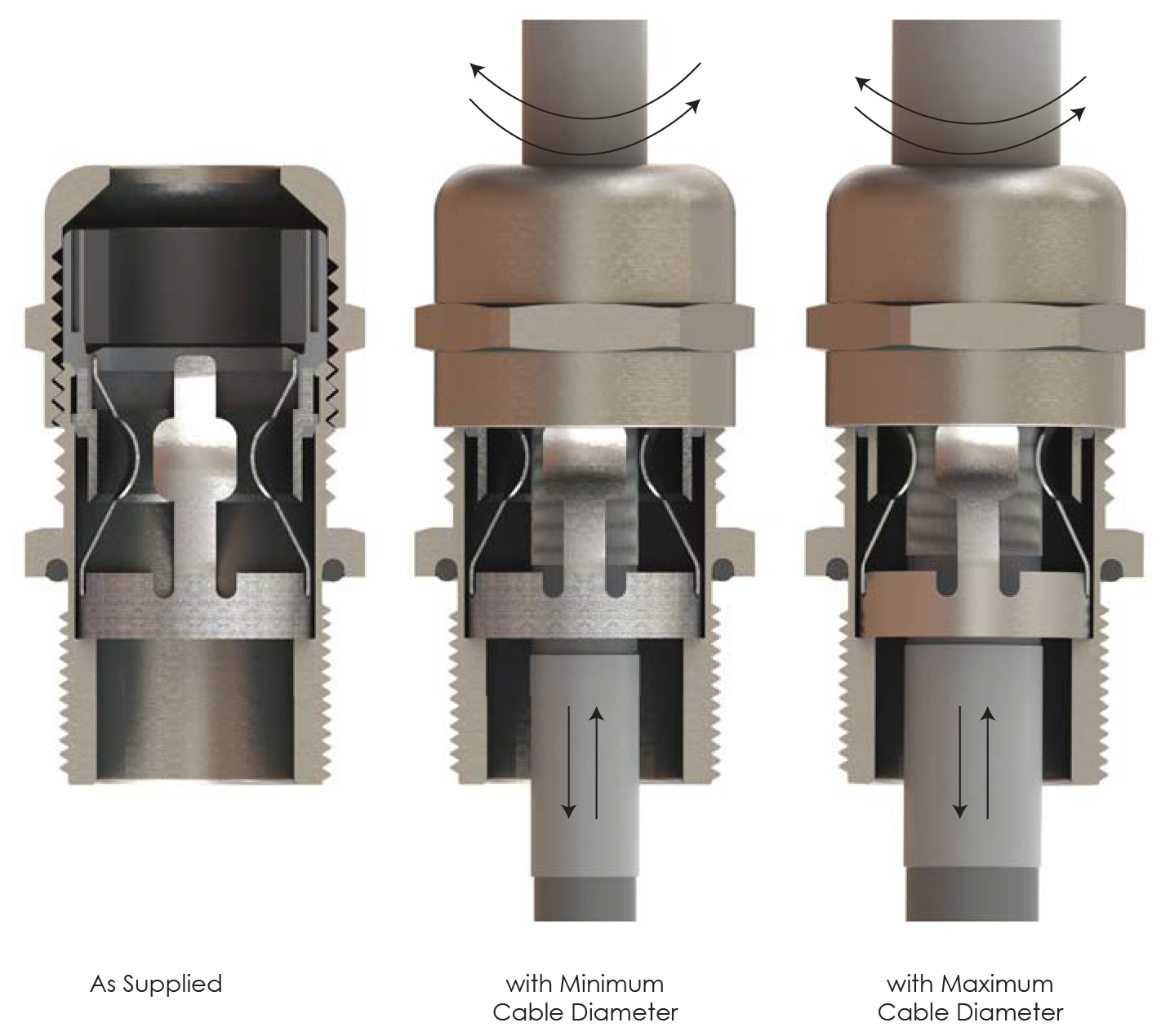

These cable glands are developed according to end users' requirements. Their features can be summarized as follows:

|

|

|

| Material | Body | Brass, nickel plated | |

|---|---|---|---|

| Cap | Brass, nickel plated | ||

| Seal | CR (chloroprene rubber) | ||

| Clamping insert | PA 6 (polyamide 6) | ||

| Contact spring | Special copper alloy | ||

| O-ring | NBR | ||

| Protection class | IP68 - 5 Bar, 30 min | ||

| Flammability | UL94 V-2 | ||

| Operating temperature | Permanent | Intermittent | |

| -20°C ÷ +100°C | -40°C ÷ +150°C | ||

| Thread type |

|

||

| Cable type | Non armoured, shielded | ||

| Accessories |

|

||

| Remarks |

|

||

| Certificate number | Standards | |

|---|---|---|

|

40039349 | Acc. to DIN EN 62444 |

|

E199260 | Acc. to UL514 |

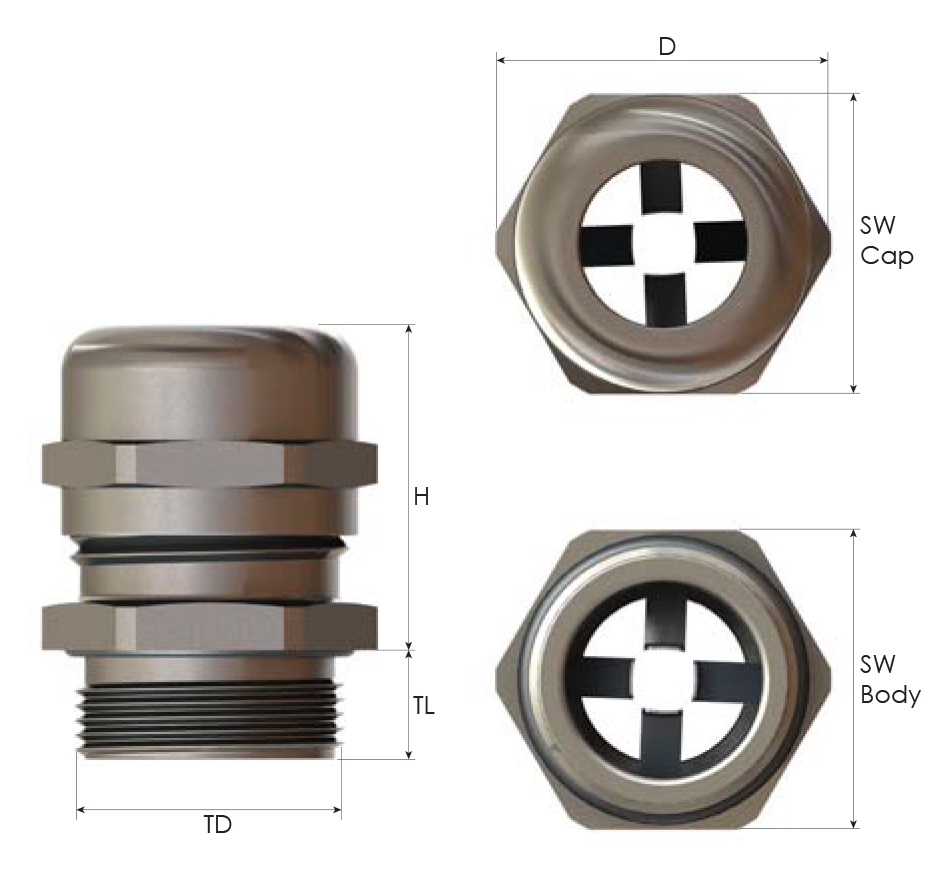

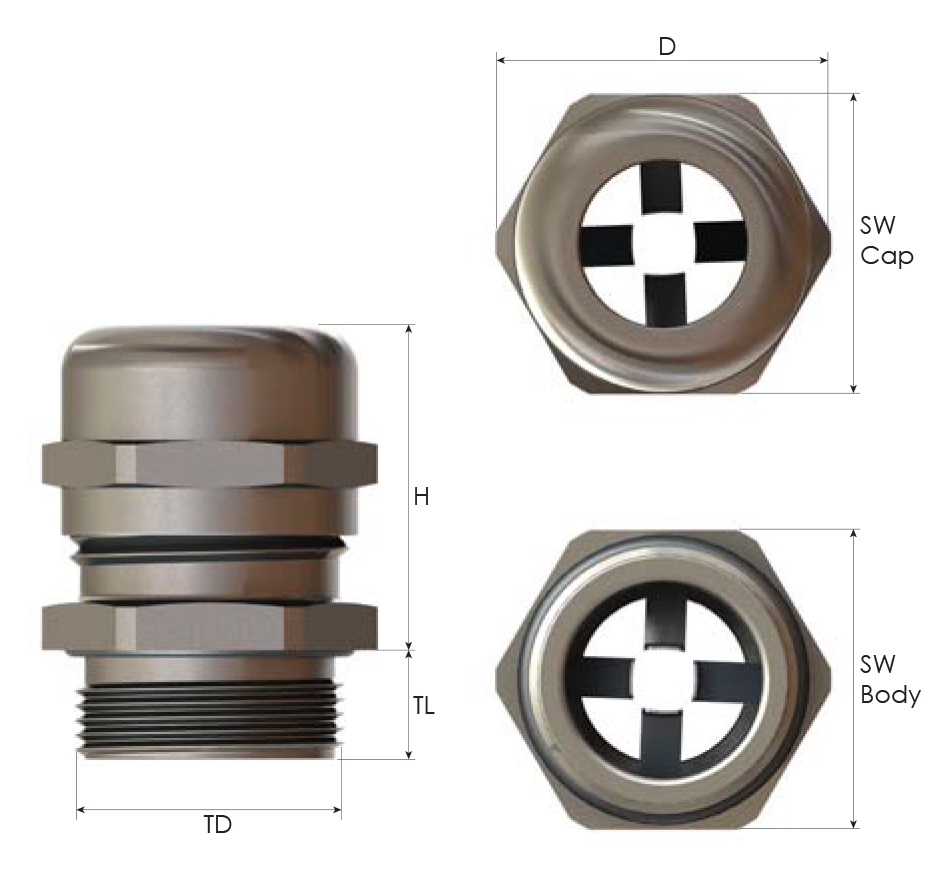

| Size | Clamping range ∅ min - max [mm] | Shield diameter ∅ min - max [mm] | Thread lenght TL [mm] | Thread ∅ TD [mm] | Spanner width | Outer ∅ D [mm] | Max. height H [mm] | Part number | Packing unit | |

|---|---|---|---|---|---|---|---|---|---|---|

| SW Cap [mm] | SW Body [mm] | |||||||||

| M12x1,5 | 3,0 - 6,5 | 2,0 - 5,0 | 6,0 | 12,0 | 14 | 14 | 15,5 | 28,0 | BMEM-ES(M12T) | 50 |

| M16x1,5 | 5,0 - 10,0 | 3,5 - 8,0 | 6,0 | 16,0 | 20 | 20 | 22,0 | 33,0 | BMEM-E1(M16T) | 50 |

| M20x1,5 | 6,0 - 12,0 | 4,5 - 10,0 | 6,0 | 20,0 | 22 | 22 | 24,5 | 32,0 | BMEM-E2S(M20T) | 50 |

| 7,5 - 14,0 | 5,5 - 11,5 | 8,0 | 24 | 26 | 26,8 | 40,0 | BMEM-E2(M20T) | |||

| M25x1,5 | 10,0 - 18,0 | 7,0 - 14,0 | 8,0 | 25,0 | 30 | 30 | 33,0 | 43,0 | BMEM-E3(M25T) | 25 |

| M32x1,5 | 16,0 - 25,0 | 12,0 - 20,0 | 9,0 | 32,0 | 40 | 40 | 43,5 | 53,0 | BMEM-E4(M32T) | 25 |

| M40x1,5 | 22,0 - 32,0 | 18,0 - 27,0 | 9,0 | 40,0 | 50 | 50 | 55,5 | 60,5 | BMEM-E5(M40T) | 20 |

| M50x1,5 | 30,0 - 38,0 | 26,0 - 34,0 | 9,0 | 50,0 | 58 | 58 | 64,0 | 73,0 | BMEM-E6(M50T) | 12 |

| M63x1,5 | 34,0 - 44,0 | 30,0 - 40,0 | 14,0 | 63,0 | 64 | 68 | 75,0 | 59,0 | BMEM-E7(M63T) | 12 |

| 37,0 - 53,0 | 33,0 - 49,0 | 10,0 | 75 | 75 | 83,0 | 75,0 | BMEM-E7L(M63T) | |||

| Size | Clamping range ∅ min - max | Shield diameter ∅ min - max | Thread lenght TL | Thread ∅ TD | Spanner width | Outer ∅ D | Max. height H | Part number | Packing unit | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [mm] | [in] | [mm] | [in] | [mm] | [in] | [mm] | [in] | SW Cap | SW Body | [mm] | [in] | [mm] | [in] | |||||

| [mm] | [in] | [mm] | [in] | |||||||||||||||

| NPT 1/4" | 3,0 - 6,5 | 0.118 - 0.256 | 2,0 - 5,0 | 0.079 - 0.197 | 11,5 | 0.453 | 13,72 | 0,540 | 14 | 0.551 | 15 | 0.591 | 16,5 | 0.610 | 28,0 | 1.102 | BNEM-ES(NPT1/4"T) | 50 |

| NPT 3/8" | 5,0 - 10,0 | 0.197 - 0.394 | 3,5 - 8,0 | 0.138 - 0.315 | 11,5 | 0.453 | 17,14 | 0.675 | 20 | 0.787 | 20 | 0.787 | 22,0 | 0.744 | 33,0 | 1.299 | BNEM-E1(NPT3/8"T) | 50 |

| NPT 1/2" | 6,0 - 12,0 | 0.236 - 0.472 | 4,5 - 10,0 | 0.177 - 0.394 | 15,0 | 0.591 | 21,34 | 0.840 | 22 | 0.866 | 22 | 0.866 | 24,5 | 0.866 | 37,5 | 1.476 | BNEM-E2S(NPT1/2"T) | 50 |

| 7,5 - 14,0 | 0.295 - 0.551 | 5,5 - 11,5 | 0.217 - 0.453 | 24 | 0.945 | 24 | 0.945 | 26,8 | 39,5 | 1.555 | BNEM-E2(NPT1/2"T) | |||||||

| NPT 3/4" | 10,0 - 18,0 | 0.394 - 0.709 | 7,0 - 14,0 | 0.276 - 0.551 | 15,0 | 0.591 | 26,67 | 1.050 | 30 | 1.181 | 30 | 1.181 | 33,0 | 0.965 | 42,5 | 1.673 | BNEM-E3(NPT3/4"T) | 25 |

| NPT 1" | 16,0 - 25,0 | 0.630 - 0.984 | 12,0 - 20,0 | 0.472 - 0.787 | 20,0 | 0.787 | 33,40 | 1.315 | 40 | 1.575 | 40 | 1.575 | 43,3 | 1.055 | 52,5 | 2.067 | BNEM-E4(NPT1"T) | 25 |

| NPT 1 1/4" | 22,0 - 32,0 | 0.866 - 1.260 | 18,0 - 27,0 | 0.709 - 1.063 | 20,0 | 0.787 | 42,16 | 1.660 | 50 | 1.969 | 50 | 1.969 | 55,4 | 1.299 | 62,0 | 2.441 | BNEM-E5(NPT11/4"T) | 20 |

| NPT 1 1/2" | 30,0 - 38,0 | 1.181 - 1.496 | 26,0 - 34,0 | 1.024 - 1.339 | 22,0 | 0.866 | 48,26 | 1.900 | 58 | 2.283 | 58 | 2.283 | 64,0 | 1.713 | 72,0 | 2.835 | BNEM-E6(NPT11/2"T) | 10 |

| NPT 2" | 34,0 - 44,0 | 1.339 - 1.732 | 30,0 - 40,0 | 1.181 - 1.575 | 22,0 | 0.866 | 60,325 | 2.375 | 64 | 2.520 | 68 | 2.677 | 75,0 | 2.185 | 71,5 | 2.815 | BNEM-E7(NPT2"T) | 5 |

| Rozmiar | Clamping range ∅ min - max [mm] | Shield diameter ∅ min - max [mm] | Thread lenght TL [mm] | Thread ∅ TD [mm] | Spanner width | Outer ∅ D [mm] | Max. height H [mm] | Part number | Packing unit | |

|---|---|---|---|---|---|---|---|---|---|---|

| SW Cap [mm] | SW Body [mm] | |||||||||

| PG 7 | 3,0 - 6,5 | 2,5 - 5,0 | 6,0 | 12,5 | 14 | 15 | 16,5 | 28,0 | BSEM-E1(Pg7T) | 50 |

| PG 11 | 5,0 - 10,0 | 3,5 - 8,0 | 6,0 | 18,6 | 20 | 21 | 23,0 | 33,0 | BSEM-E3(Pg11T) | 50 |

| PG 13,5 | 6,0 - 12,0 | 4,5 - 10,0 | 6,5 | 20,4 | 22 | 22 | 24,5 | 31,5 | BSEM-E4(Pg13,5T) | 50 |

| PG 16 | 7,5 - 14,0 | 5,5 - 11,5 | 6,5 | 22,5 | 24 | 25 | 27,5 | 39,5 | BSEM-E5(Pg16T) | 25 |

| PG 21 | 10,0 - 18,0 | 7,0 - 14,0 | 7,0 | 28,3 | 32 | 30 | 35,5 | 42,5 | BSEM-E6(Pg21T) | 25 |

| PG 29 | 16,0 - 25,0 | 12,0 - 20,0 | 9,0 | 37,0 | 40 | 40 | 43,5 | 52,5 | BSEM-E7(Pg29T) | 25 |

| PG 36 | 22,0 - 32,0 | 18,0 - 27,0 | 9,0 | 47,0 | 50 | 50 | 55,5 | 60,5 | BSEM-E8(Pg36T) | 20 |

| PG 42 | 30,0 - 38,0 | 26,0 - 34,0 | 12,0 | 54,0 | 58 | 60 | 66,5 | 72,5 | BSEM-E9(Pg42T) | 10 |

| PG 48 | 34,0 - 44,0 | 30,0 - 40,0 | 14,0 | 59,3 | 64 | 68 | 75,0 | 58,5 | BSEM-E10(Pg48T) | 5 |

Are you interested in this product? Do you need additional information or individual pricing?

These cable glands are developed according to end users' requirements. Their features can be summarized as follows:

|

|

|

| Material | Body | Brass, nickel plated | |

|---|---|---|---|

| Cap | Brass, nickel plated | ||

| Seal | CR (chloroprene rubber) | ||

| Clamping insert | PA 6 (polyamide 6) | ||

| Contact spring | Special copper alloy | ||

| O-ring | NBR | ||

| Protection class | IP68 - 5 Bar, 30 min | ||

| Flammability | UL94 V-2 | ||

| Operating temperature | Permanent | Intermittent | |

| -20°C ÷ +100°C | -40°C ÷ +150°C | ||

| Thread type |

|

||

| Cable type | Non armoured, shielded | ||

| Accessories |

|

||

| Remarks |

|

||

| Certificate number | Standards | |

|---|---|---|

|

40039349 | Acc. to DIN EN 62444 |

|

E199260 | Acc. to UL514 |

| Size | Clamping range ∅ min - max [mm] | Shield diameter ∅ min - max [mm] | Thread lenght TL [mm] | Thread ∅ TD [mm] | Spanner width | Outer ∅ D [mm] | Max. height H [mm] | Part number | Packing unit | |

|---|---|---|---|---|---|---|---|---|---|---|

| SW Cap [mm] | SW Body [mm] | |||||||||

| M12x1,5 | 3,0 - 6,5 | 2,0 - 5,0 | 6,0 | 12,0 | 14 | 14 | 15,5 | 28,0 | BMEM-ES(M12T) | 50 |

| M16x1,5 | 5,0 - 10,0 | 3,5 - 8,0 | 6,0 | 16,0 | 20 | 20 | 22,0 | 33,0 | BMEM-E1(M16T) | 50 |

| M20x1,5 | 6,0 - 12,0 | 4,5 - 10,0 | 6,0 | 20,0 | 22 | 22 | 24,5 | 32,0 | BMEM-E2S(M20T) | 50 |

| 7,5 - 14,0 | 5,5 - 11,5 | 8,0 | 24 | 26 | 26,8 | 40,0 | BMEM-E2(M20T) | |||

| M25x1,5 | 10,0 - 18,0 | 7,0 - 14,0 | 8,0 | 25,0 | 30 | 30 | 33,0 | 43,0 | BMEM-E3(M25T) | 25 |

| M32x1,5 | 16,0 - 25,0 | 12,0 - 20,0 | 9,0 | 32,0 | 40 | 40 | 43,5 | 53,0 | BMEM-E4(M32T) | 25 |

| M40x1,5 | 22,0 - 32,0 | 18,0 - 27,0 | 9,0 | 40,0 | 50 | 50 | 55,5 | 60,5 | BMEM-E5(M40T) | 20 |

| M50x1,5 | 30,0 - 38,0 | 26,0 - 34,0 | 9,0 | 50,0 | 58 | 58 | 64,0 | 73,0 | BMEM-E6(M50T) | 12 |

| M63x1,5 | 34,0 - 44,0 | 30,0 - 40,0 | 14,0 | 63,0 | 64 | 68 | 75,0 | 59,0 | BMEM-E7(M63T) | 12 |

| 37,0 - 53,0 | 33,0 - 49,0 | 10,0 | 75 | 75 | 83,0 | 75,0 | BMEM-E7L(M63T) | |||

| Size | Clamping range ∅ min - max | Shield diameter ∅ min - max | Thread lenght TL | Thread ∅ TD | Spanner width | Outer ∅ D | Max. height H | Part number | Packing unit | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [mm] | [in] | [mm] | [in] | [mm] | [in] | [mm] | [in] | SW Cap | SW Body | [mm] | [in] | [mm] | [in] | |||||

| [mm] | [in] | [mm] | [in] | |||||||||||||||

| NPT 1/4" | 3,0 - 6,5 | 0.118 - 0.256 | 2,0 - 5,0 | 0.079 - 0.197 | 11,5 | 0.453 | 13,72 | 0,540 | 14 | 0.551 | 15 | 0.591 | 16,5 | 0.610 | 28,0 | 1.102 | BNEM-ES(NPT1/4"T) | 50 |

| NPT 3/8" | 5,0 - 10,0 | 0.197 - 0.394 | 3,5 - 8,0 | 0.138 - 0.315 | 11,5 | 0.453 | 17,14 | 0.675 | 20 | 0.787 | 20 | 0.787 | 22,0 | 0.744 | 33,0 | 1.299 | BNEM-E1(NPT3/8"T) | 50 |

| NPT 1/2" | 6,0 - 12,0 | 0.236 - 0.472 | 4,5 - 10,0 | 0.177 - 0.394 | 15,0 | 0.591 | 21,34 | 0.840 | 22 | 0.866 | 22 | 0.866 | 24,5 | 0.866 | 37,5 | 1.476 | BNEM-E2S(NPT1/2"T) | 50 |

| 7,5 - 14,0 | 0.295 - 0.551 | 5,5 - 11,5 | 0.217 - 0.453 | 24 | 0.945 | 24 | 0.945 | 26,8 | 39,5 | 1.555 | BNEM-E2(NPT1/2"T) | |||||||

| NPT 3/4" | 10,0 - 18,0 | 0.394 - 0.709 | 7,0 - 14,0 | 0.276 - 0.551 | 15,0 | 0.591 | 26,67 | 1.050 | 30 | 1.181 | 30 | 1.181 | 33,0 | 0.965 | 42,5 | 1.673 | BNEM-E3(NPT3/4"T) | 25 |

| NPT 1" | 16,0 - 25,0 | 0.630 - 0.984 | 12,0 - 20,0 | 0.472 - 0.787 | 20,0 | 0.787 | 33,40 | 1.315 | 40 | 1.575 | 40 | 1.575 | 43,3 | 1.055 | 52,5 | 2.067 | BNEM-E4(NPT1"T) | 25 |

| NPT 1 1/4" | 22,0 - 32,0 | 0.866 - 1.260 | 18,0 - 27,0 | 0.709 - 1.063 | 20,0 | 0.787 | 42,16 | 1.660 | 50 | 1.969 | 50 | 1.969 | 55,4 | 1.299 | 62,0 | 2.441 | BNEM-E5(NPT11/4"T) | 20 |

| NPT 1 1/2" | 30,0 - 38,0 | 1.181 - 1.496 | 26,0 - 34,0 | 1.024 - 1.339 | 22,0 | 0.866 | 48,26 | 1.900 | 58 | 2.283 | 58 | 2.283 | 64,0 | 1.713 | 72,0 | 2.835 | BNEM-E6(NPT11/2"T) | 10 |

| NPT 2" | 34,0 - 44,0 | 1.339 - 1.732 | 30,0 - 40,0 | 1.181 - 1.575 | 22,0 | 0.866 | 60,325 | 2.375 | 64 | 2.520 | 68 | 2.677 | 75,0 | 2.185 | 71,5 | 2.815 | BNEM-E7(NPT2"T) | 5 |

| Rozmiar | Clamping range ∅ min - max [mm] | Shield diameter ∅ min - max [mm] | Thread lenght TL [mm] | Thread ∅ TD [mm] | Spanner width | Outer ∅ D [mm] | Max. height H [mm] | Part number | Packing unit | |

|---|---|---|---|---|---|---|---|---|---|---|

| SW Cap [mm] | SW Body [mm] | |||||||||

| PG 7 | 3,0 - 6,5 | 2,5 - 5,0 | 6,0 | 12,5 | 14 | 15 | 16,5 | 28,0 | BSEM-E1(Pg7T) | 50 |

| PG 11 | 5,0 - 10,0 | 3,5 - 8,0 | 6,0 | 18,6 | 20 | 21 | 23,0 | 33,0 | BSEM-E3(Pg11T) | 50 |

| PG 13,5 | 6,0 - 12,0 | 4,5 - 10,0 | 6,5 | 20,4 | 22 | 22 | 24,5 | 31,5 | BSEM-E4(Pg13,5T) | 50 |

| PG 16 | 7,5 - 14,0 | 5,5 - 11,5 | 6,5 | 22,5 | 24 | 25 | 27,5 | 39,5 | BSEM-E5(Pg16T) | 25 |

| PG 21 | 10,0 - 18,0 | 7,0 - 14,0 | 7,0 | 28,3 | 32 | 30 | 35,5 | 42,5 | BSEM-E6(Pg21T) | 25 |

| PG 29 | 16,0 - 25,0 | 12,0 - 20,0 | 9,0 | 37,0 | 40 | 40 | 43,5 | 52,5 | BSEM-E7(Pg29T) | 25 |

| PG 36 | 22,0 - 32,0 | 18,0 - 27,0 | 9,0 | 47,0 | 50 | 50 | 55,5 | 60,5 | BSEM-E8(Pg36T) | 20 |

| PG 42 | 30,0 - 38,0 | 26,0 - 34,0 | 12,0 | 54,0 | 58 | 60 | 66,5 | 72,5 | BSEM-E9(Pg42T) | 10 |

| PG 48 | 34,0 - 44,0 | 30,0 - 40,0 | 14,0 | 59,3 | 64 | 68 | 75,0 | 58,5 | BSEM-E10(Pg48T) | 5 |

Why does my PCB design fail EMC tests?

Why does my PCB design fail EMC tests?

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent