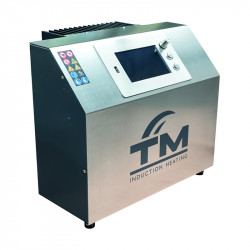

Induction heater EASYHEAT

Categories

EASYHEAT is a family of compact induction heating systems designed for fast, precise, and repeatable delivery of heat to metal parts. These systems are widely used in industry — from machinery service to manufacturing — wherever non-contact, directed heating of components is needed.

Why choose EASYHEAT — key advantages

EASYHEAT offers several competitive advantages: heating speed, high temperature precision, process repeatability, and relatively low energy loss — as the energy is focused only on the part being heated. This makes processes such as bearing installation or soldering faster and more controlled than with convective heat sources.

Power and frequency range — for what tasks?

The EASYHEAT series is available in a wide power range — from small, portable units (hundreds of watts to a few kilowatts) to efficient systems with a power of over ten kW and more. The typical operating frequency band is in the range of several hundred kHz (e.g., 150–400 kHz), which allows for optimization of the heat penetration depth depending on the size and shape of the component. These parameters make EASYHEAT suitable for heating small components (e.g., sleeves, bearings) and for applications requiring controlled preheating.

Selected models and configurations available from the distributor

Various EASYHEAT variants are available on the market — from the "Air" version (small, air-cooled units) to larger, stationary systems with higher power and temperature control options. Examples of specific models (e.g., EASYHEAT 305, EASYHEAT 755) and equipment variants can be found in the distributor's offer, who tailors the configuration to the client's requirements.

Practical applications — where does it work best?

Typical EASYHEAT applications include: heating bearings before mounting, heating sleeves and gears, shrink-fitting, soldering and overlay welding, as well as service and assembly operations requiring fast, local heating without affecting adjacent components. In workshop and production applications, these devices accelerate processes and minimize the risk of thermal damage.

How to choose an EASYHEAT model — practical tips

When selecting a model, it is worth paying attention to: nominal power (matched to the size and mass of the part being heated), frequency range (for the required penetration depth), the ability to regulate heating cycles, and temperature control options. For small and precise parts, units with higher frequency and lower power are often better; for larger components — more powerful systems with cooling capability.

Safety and service

Induction heaters are industrial-grade electrical devices — they require proper power supply, grounding, and compliance with OHS regulations when working with hot components. When choosing a supplier, it is worth ensuring the availability of service, spare parts, and operating instructions and training opportunities. Local distribution companies offer configuration selection and service support.

Frequently Asked Questions (FAQ)

How quickly will a bearing heat up? — The time depends on the bearing size, device power, and set profile; EASYHEAT allows for fast, controlled cycles, often counted in seconds or minutes for typical applications.

Do induction heaters damage bearings? — With proper use (temperature control and appropriate time) the risk of damage is minimal — the heating is superficial and controlled, and the energy is focused exclusively on the working component.