Category

Photos are for informational purposes only. View product specification

please use latin characters

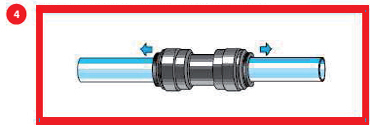

John Guest push-in fittings ensure a durable, secure, and tight connection between the pipe and the connecting element.

John Guest push-in fittings are ideal for complex piping systems, as well as for training and inspection equipment where frequent connection and disconnection of lines is necessary.

|

Connection Ø 4 mm - Ø 22 mm

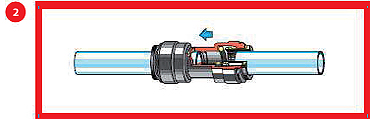

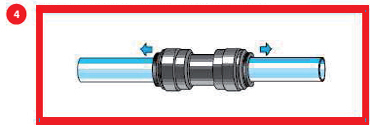

Cut the pipe at a right angle and remove any burrs. Check that the pipe is free of sharp edges, longitudinal scratches, and other damage. The connection holds even before sealing.

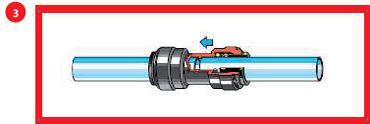

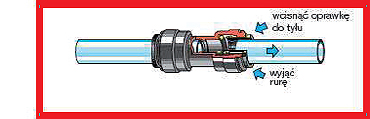

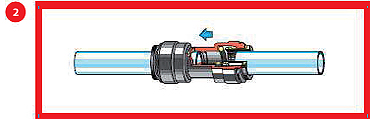

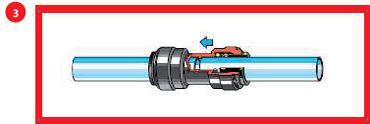

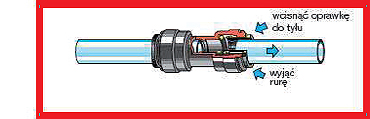

The coupling grips the pipe even before sealing. Insert the pipe as far as it will go.  Insert the pipe as far as it will go. The fitting has stainless steel teeth that secure the pipe in the fitting. The ring seal creates a perfectly tight connection. Checking the connection by pulling the pipe  Check that the pipe is securely seated. This can be verified by pulling the pipe in opposite directions. Disconnecting the connection  The pipe can be disconnected by pushing the fitting backwards. |

Pipe system technology 0 28 mm

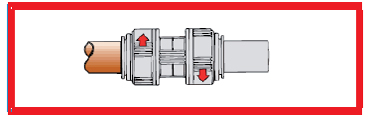

New 28 mm fittings The Speedfit series has been expanded to the 28 mm dimension. Like all Speedfit fittings, it features a stainless steel serrated frame and an O-ring seal, ensuring excellent strength and a leak-proof connection. The fittings can be assembled and disassembled without tools.  Creating a 28 mm pipe system connection As with other sizes, a secure connection can also be made by simply inserting the pipe into the fitting. Turning the nut 1/4 turn (1 audible click) double-secures the connection and compresses the seal to the pipe's outer diameter. This action reduces the possibility of longitudinal and lateral displacement of the pipe.   Disconnecting the pipe system connection by 28 mm To disconnect the push-in pipe connection, turn the nut 1/4 turn counterclockwise. The connection is unlocked and can be disconnected by pressing the socket. (see Disconnecting a 4-22 mm connection) |

|

|

|

| Temperature | pressure* about 4-8 mm 5/32“-5/16“ |

pressure* about 10-28 mm 3/8“-1/2“ |

|---|---|---|

| Air -20 °C |

16 bar | 10 bar |

| Liquids and air |

||

| +1 °C | 16 bar | 10 bar |

| +23 °C | 16 bar | 10 bar |

| +70 °C | 10 bar | 7 bar |

| avg. external pipes (in inches) | 5/32“-3/16 | 1/4“-1/2“ |

|---|---|---|

| Tolerances (inches) | +0.001“/-0.003“ +0.03/-0.08mm) |

+0.001“/-0.004“ (+0.03/-0.10mm) |

Are you interested in this product? Do you need additional information or individual pricing?

John Guest push-in fittings ensure a durable, secure, and tight connection between the pipe and the connecting element.

John Guest push-in fittings are ideal for complex piping systems, as well as for training and inspection equipment where frequent connection and disconnection of lines is necessary.

|

Connection Ø 4 mm - Ø 22 mm

Cut the pipe at a right angle and remove any burrs. Check that the pipe is free of sharp edges, longitudinal scratches, and other damage. The connection holds even before sealing.

The coupling grips the pipe even before sealing. Insert the pipe as far as it will go.  Insert the pipe as far as it will go. The fitting has stainless steel teeth that secure the pipe in the fitting. The ring seal creates a perfectly tight connection. Checking the connection by pulling the pipe  Check that the pipe is securely seated. This can be verified by pulling the pipe in opposite directions. Disconnecting the connection  The pipe can be disconnected by pushing the fitting backwards. |

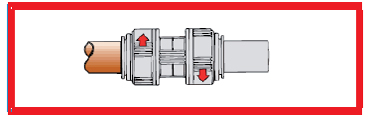

Pipe system technology 0 28 mm

New 28 mm fittings The Speedfit series has been expanded to the 28 mm dimension. Like all Speedfit fittings, it features a stainless steel serrated frame and an O-ring seal, ensuring excellent strength and a leak-proof connection. The fittings can be assembled and disassembled without tools.  Creating a 28 mm pipe system connection As with other sizes, a secure connection can also be made by simply inserting the pipe into the fitting. Turning the nut 1/4 turn (1 audible click) double-secures the connection and compresses the seal to the pipe's outer diameter. This action reduces the possibility of longitudinal and lateral displacement of the pipe.   Disconnecting the pipe system connection by 28 mm To disconnect the push-in pipe connection, turn the nut 1/4 turn counterclockwise. The connection is unlocked and can be disconnected by pressing the socket. (see Disconnecting a 4-22 mm connection) |

|

|

|

| Temperature | pressure* about 4-8 mm 5/32“-5/16“ |

pressure* about 10-28 mm 3/8“-1/2“ |

|---|---|---|

| Air -20 °C |

16 bar | 10 bar |

| Liquids and air |

||

| +1 °C | 16 bar | 10 bar |

| +23 °C | 16 bar | 10 bar |

| +70 °C | 10 bar | 7 bar |

| avg. external pipes (in inches) | 5/32“-3/16 | 1/4“-1/2“ |

|---|---|---|

| Tolerances (inches) | +0.001“/-0.003“ +0.03/-0.08mm) |

+0.001“/-0.004“ (+0.03/-0.10mm) |

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent