Rotary Connectors

Categories

Reliable Rotary Joints

In our assortment, you can find high-quality industrial connectors for many years. Our products are intended for professional applications. We have many years of experience in sales, which allows us to provide you with assistance and professional advice in selecting the right solutions.

In our offer, we have electrical rotary joints filled with mercury (single, multi-contact, with a through hole), and we also manufacture custom connectors, tailored to your projects. All offered products are made of high-quality materials, which translates into the longevity and durability of the connectors. Our products are used in various enterprises. The parameters of our devices are precisely described, which significantly increases safety during operation and allows for selecting the exact device for a given application.

Using our products increases work efficiency and installation durability.

Also check busbar connectors.

Rotary Joints – Introduction

Rotary joints, also known as slip rings, are installed in many machines and devices. They allow the connection of moving parts with stationary ones in a way that ensures uninterrupted transmission of electrical power, signals, and data. Their use increases the reliability and efficiency of rotating devices, from construction machines, through medical devices, to aviation and energy systems. In practice, rotary joints allow machines to operate smoothly without the risk of wire damage or transmission interference.

What is a Rotary Joint (Slip Ring)?

A rotary joint is an electrical device that enables the transmission of current, voltage, and signals between the moving and stationary parts of a machine. Its main function is to ensure continuous transmission of power and data even during continuous rotational movement, which is essential in many industrial and technological applications.

Rotary joints are also known by other names, such as rotary electrical contacts or commutators, depending on the application and industry. Their versatility makes them suitable for both simple machines and advanced automation and robotics systems.

Construction of Rotary Joints (Slip Ring)

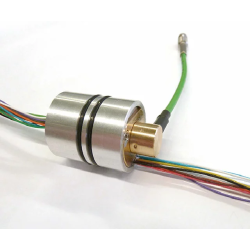

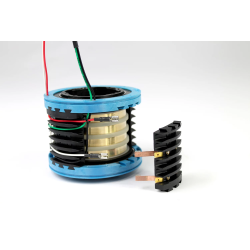

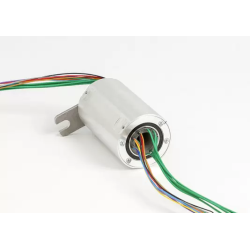

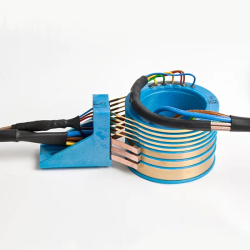

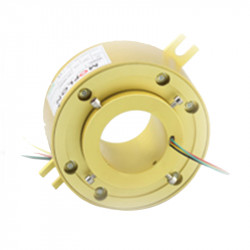

Rotary joints consist of precisely matched components that enable reliable transmission of power and signals during rotational movement. Their construction uses high-quality conductive materials such as copper, silver, or gold, which ensure minimal energy loss and durability in long-term operation.

Rotary joints come in various shapes and sizes, tailored to specific machines and devices. We encounter flat (pancake), through-hole, miniature, fiber-optic, and specialized types for the aerospace, medical, or energy industries.

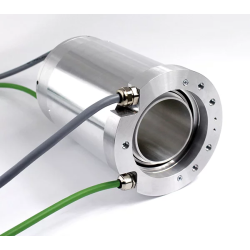

Additionally, many connectors are equipped with protective elements, such as covers against dust and moisture, as well as mounting brackets for stable installation. This ensures that devices remain safe, and the joints operate smoothly even in demanding industrial conditions.

Operating Principle

Rotary joints enable the transmission of electrical power and signals between moving and stationary parts of a machine without interrupting rotation. Power and data are transmitted through conductive rings and sliding contacts, which maintain constant contact even during continuous movement.

Some models also offer the possibility of transmitting other media – such as liquids or optical signals – allowing for more advanced applications. This enables rotary joints not only to power machines but also to transmit information from sensors, control signals, or working media, providing comprehensive operation of rotating devices.

Advantages of Using Rotary Joints

Rotary joints (slip rings) offer a range of benefits, making them indispensable in modern machines and devices. Primarily, they provide stable transmission of power and signals, eliminating the risk of disturbances and downtime in rotating devices.

Another advantage is the ability to precisely regulate power and speed in machines and motors, which is particularly important in processes requiring gradual energy increase or rotation control.

Additionally, rotary joints are highly resistant to harsh working conditions – they operate stably in high and low temperatures, under mechanical load, and with increased pressure. This makes them reliable across a wide range of industrial applications.

Applications of Rotary Joints

Rotary joints are used in many industries due to their versatility and reliability. In construction, packaging, and electronics, they support the operation of rotating machines, robots, and automation systems.

In the energy, aviation, water, and wastewater sectors, they enable safe transmission of power and signals in devices operating in harsh environmental conditions.

We should also mention the medical and pharmaceutical industries, where rotary joints support precise diagnostic devices, laboratory systems, and drug manufacturing machines, ensuring reliable power and data flow in areas requiring the highest precision.

Types of Rotary Joints

Rotary joints come in many variants, adapted to diverse industrial applications:

- Pancake (flat) – characterized by a compact design, ideal for spaces with limited room, enabling power and signal transmission in a flat configuration.

- Through-hole – feature a hole in the center through which a shaft or other structural elements can pass, facilitating integration with rotating machines.

- Ethernet, miniature, and fiber-optic – intended for high-speed data transmission and precise systems such as industrial automation or robotics.

- Specialized types for specific industries – include connectors adapted to operate in extreme temperatures, under pressure, or in chemical or medical environments, ensuring reliable operation in demanding conditions.

How to Choose the Right Rotary Joint

Selecting the appropriate rotary joint requires considering several key factors:

- Electrical parameters – check the maximum current and voltage the joint can transmit, as well as the type of signals (analog, digital, fiber-optic).

- Working conditions – ambient temperature, pressure, presence of moisture, dust, or vibrations affect the durability and reliability of the joint.

- Operating hours and maintenance – it is important to determine the expected lifespan of the joint and the possibilities for servicing and replacing sliding contacts.

Proper selection of a rotary joint ensures stable and trouble-free machine operation and optimal transmission of power and data, minimizing the risk of failures and downtime.

Installation of Rotary Joints

Installing rotary joints is straightforward but requires following proper guidelines to ensure correct and reliable operation. Typically, the joint is placed in a hole in the stationary part of the machine and secured with screws or mounting brackets.

It is important to tighten all screws evenly to avoid looseness or excessive stress, which could lead to premature wear of the joint. During installation, stability of the device should also be ensured so that the joint operates smoothly even during continuous rotation and mechanical loads.

Additionally, it is recommended to protect the joint against dust, moisture, and overloads, e.g., with protective covers, which extends its lifespan and ensures reliable operation in harsh industrial conditions.

Use and Maintenance

Rotary joints have a long lifespan, provided they operate under optimal conditions. Avoid excessive load, vibration, and exposure to extreme temperatures or moisture if the joint is not designed for such conditions.

Regular monitoring of wear – including checking sliding contacts and wires – allows detection of potential problems before they affect machine operation. If necessary, proper maintenance such as lubricating contacts or replacing worn components ensures long and trouble-free operation of the rotary joint.

Summary

Rotary joints (slip rings) are components of industrial machines and devices that enable the transmission of power, signals, and data between moving and stationary parts. They allow smooth, reliable operation of rotating devices without the risk of wire damage or transmission interference.

Their versatility makes them applicable in many industries – from construction, packaging, and electronics to energy, aviation, water, and medicine. Rotary joints come in various types and sizes, including through-hole, flat, miniature, fiber-optic, and specialized models for demanding applications.

Proper selection, installation, and regular maintenance of rotary joints ensure their long life, reliability, and operational stability. This makes rotary joints an indispensable solution in any machine where a moving part must work with a stationary part, and the transmission of power and data must occur without disruption.