Category

Photos are for informational purposes only. View product specification

please use latin characters

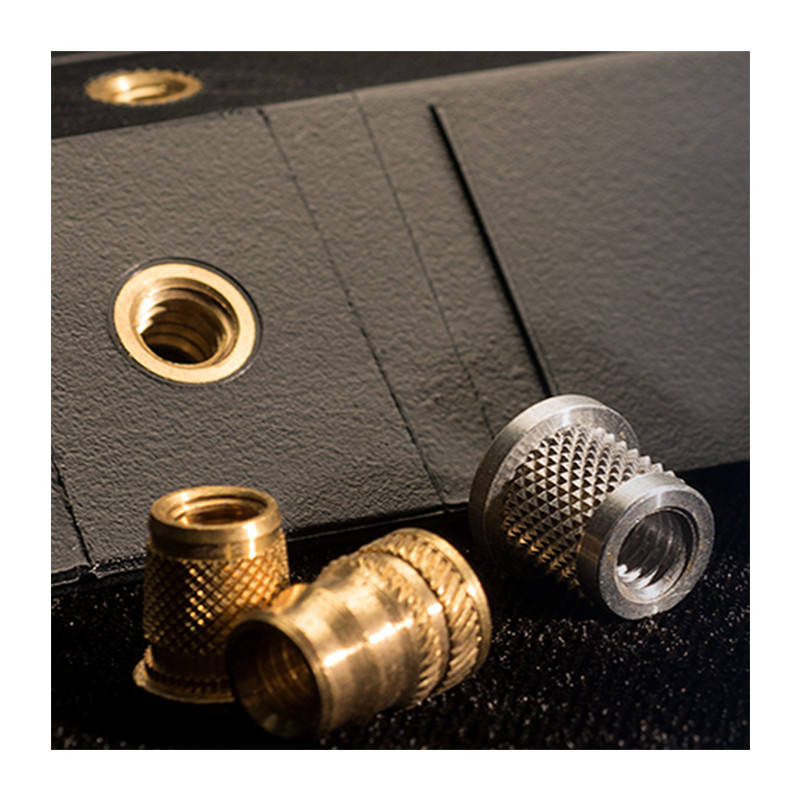

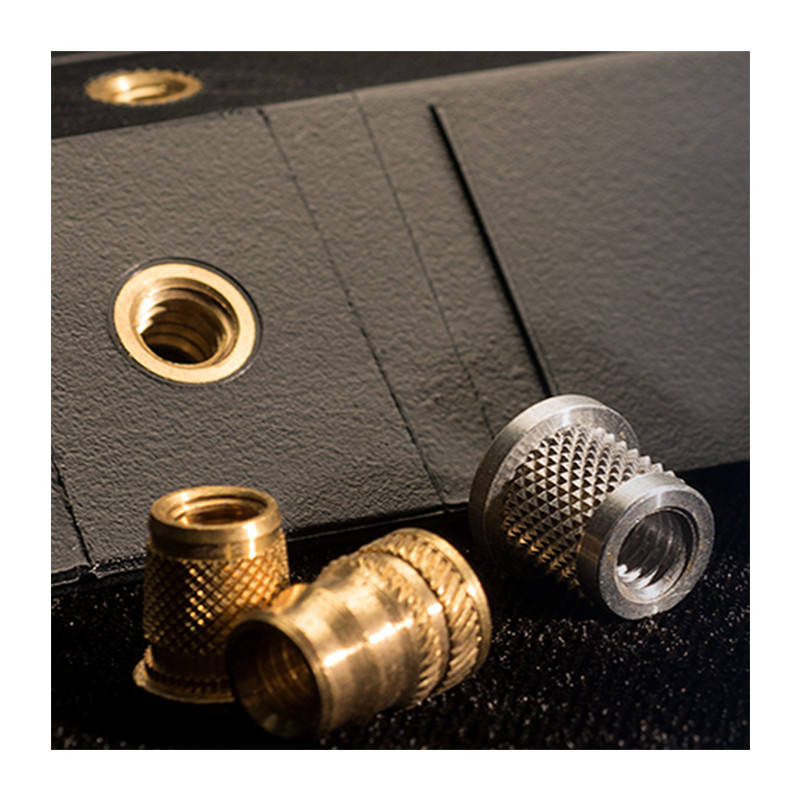

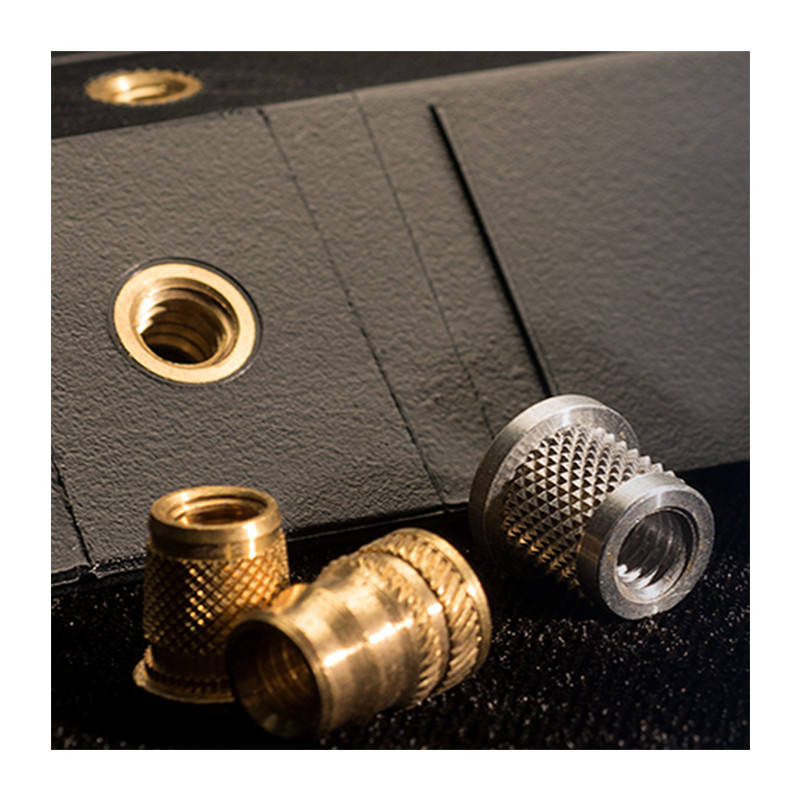

When a structural component is produced from a thermoplastic material, it is possible to heat a threaded metal insert to a temperature above the plastic reflow point and press it into the plastic part. There are many types of metal inserts, specially designed for retention strength, produced for this purpose. With the increasing need for lighter, stronger structural components, metal inserts are now frequently used when strong threaded connections are required. Metal to plastic bonding is one of several plastic reflow appli-cations for induction heating. Other processes involving heating plastic to a liquidous state include metal reclaiming and thermoplastic composite manufacturing.

The metal to plastic bonding process requires fast, accurate and repeatable heating to avoid such quality defects as flashing (molten plastic overflow) and burning. Modern induction heating systems quickly heat the inserts from the outside surface, limiting the heat energy to the outer edges where heat is needed to reflow the plastic. Longer heating cycles may result in the softening of the internal threads, especially at the low temperatures needed for heating brass inserts. Heating with induction is reliable, repeatable, non-contact and energy-efficient. Solid state systems, when used in conjunction with temperature sensing and control equipment, are capable of heating very small areas within precise production tolerances.

Typical RF power supplies for metal to plastic bonding range from 1 to 20kW, depending on the parts and application requirements.

Are you interested in this product? Do you need additional information or individual pricing?

When a structural component is produced from a thermoplastic material, it is possible to heat a threaded metal insert to a temperature above the plastic reflow point and press it into the plastic part. There are many types of metal inserts, specially designed for retention strength, produced for this purpose. With the increasing need for lighter, stronger structural components, metal inserts are now frequently used when strong threaded connections are required. Metal to plastic bonding is one of several plastic reflow appli-cations for induction heating. Other processes involving heating plastic to a liquidous state include metal reclaiming and thermoplastic composite manufacturing.

The metal to plastic bonding process requires fast, accurate and repeatable heating to avoid such quality defects as flashing (molten plastic overflow) and burning. Modern induction heating systems quickly heat the inserts from the outside surface, limiting the heat energy to the outer edges where heat is needed to reflow the plastic. Longer heating cycles may result in the softening of the internal threads, especially at the low temperatures needed for heating brass inserts. Heating with induction is reliable, repeatable, non-contact and energy-efficient. Solid state systems, when used in conjunction with temperature sensing and control equipment, are capable of heating very small areas within precise production tolerances.

Typical RF power supplies for metal to plastic bonding range from 1 to 20kW, depending on the parts and application requirements.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent