Category

Photos are for informational purposes only. View product specification

please use latin characters

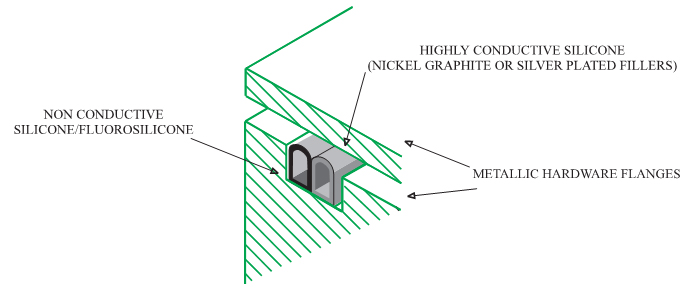

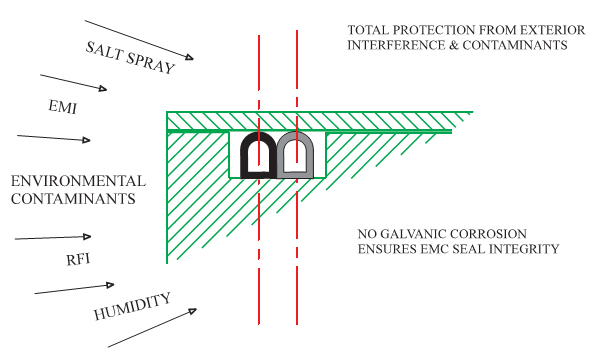

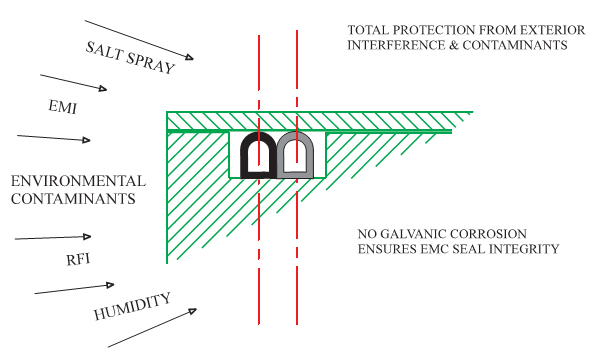

Freedom from galvanic corrosion of joints at a sealing interface using conductive elastomeric gaskets is a fundamental consideration in certain environments. In some cases it is possible to select a suitable combination of materials to mitigate the effects, but sometimes it is necessary to include an additional environmental seal.

The duplicity of seals can perform extremely well but has a fundamental problem of packaging. Two gaskets require a large amount of volume, particularly if one uses two ‘O’ ring grooves.

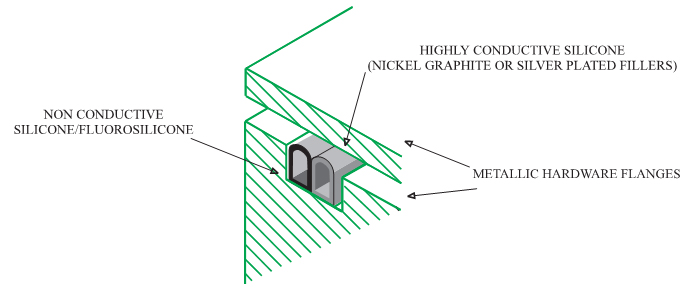

T C Shielding has specifically developed “duo-extrusion” to offer a compact, space efficient gasket. The duo-extrusion comprises two materials with a vulcanised seamed joint. One component is conductive, providing an effective EMC gasket, the other component is an environmental seal in non-conductive silicone or fluorosilicone. The environmental component effectively protects the EMC gasket from external contaminants, including moisture, thus preventing galvanic corrosion

Materials used can be silver aluminium, silver copper or nickel graphite silicones for the conductive seal, and silicone or fluorosilicone for the non-conductive sealing element.

Summary of features:

The product is produced by continuous process and can be supplied in strip, roll or conductive vulcanised to form a jointed ring.

Developed to address the dual requirements of environmental sealing and high levels of AEMC shielding.

Eliminates the potential for galvanic corrosion associated with highly conductive materials when used with dissimilar metallic hardware.

‘DUO SEAL’ FROM T C SHIELDING - THE ULTIMATE PROTECTION

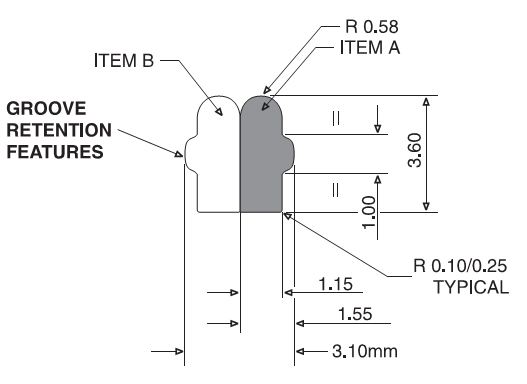

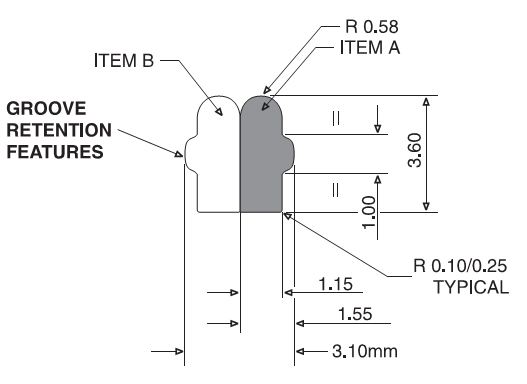

ITEM A : CONDUCTIVE R/F SEAL

ITEM B : NON-CONDUCTIVE SEAL

NOTES:

MAXIMUM SECTIONAL AREA = 5.13mm PER SECTION

ITEMS A AND B ARE CO-VULCANISED

DUO SEAL PART No. ES-XX-176

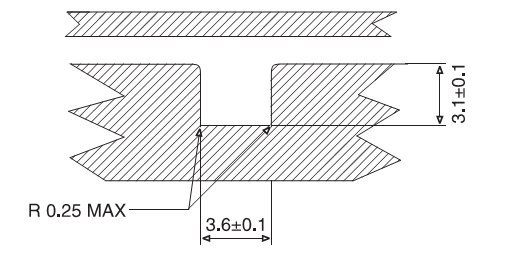

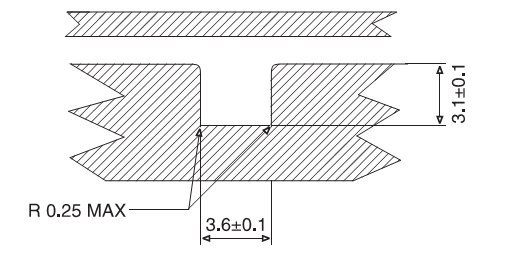

REKOMENDOWANE WYMIARY ROwka DLA DUO SEAL ES-XX-176

NOTES ON DUO SEAL REF: ES-XX-176

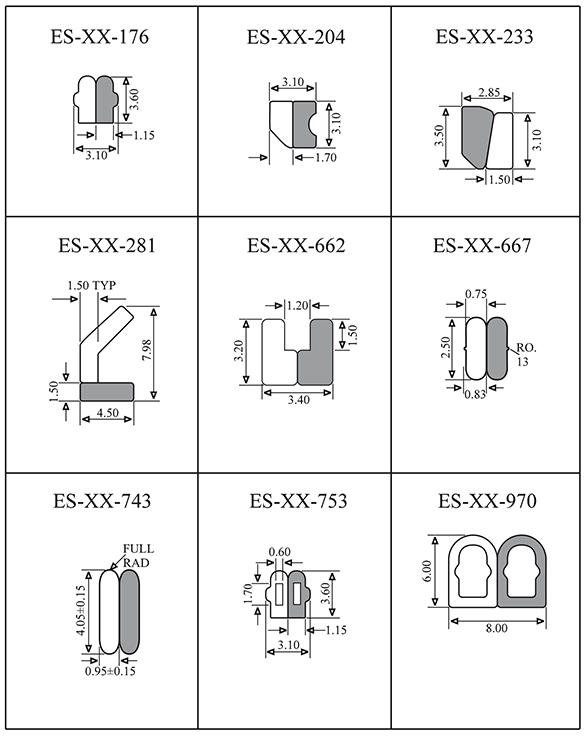

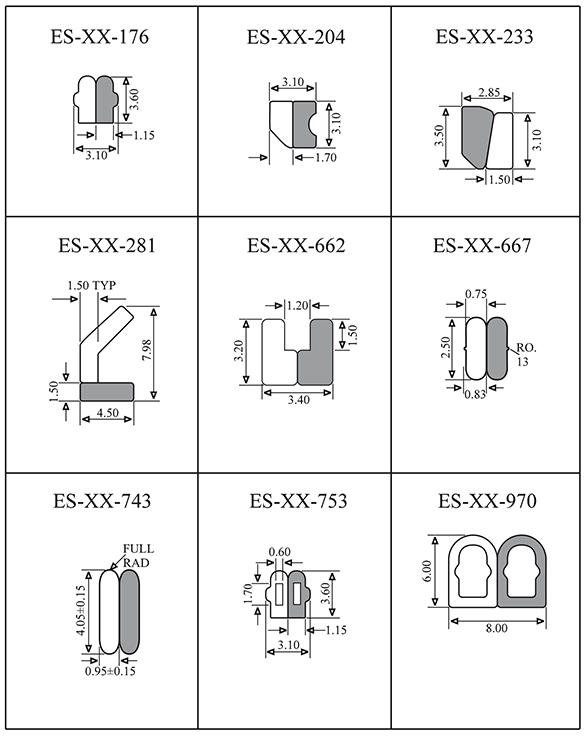

Non standard profiles that have been developed to suit specific customer applications for high spec RFI / IP applications.

Are you interested in this product? Do you need additional information or individual pricing?

Freedom from galvanic corrosion of joints at a sealing interface using conductive elastomeric gaskets is a fundamental consideration in certain environments. In some cases it is possible to select a suitable combination of materials to mitigate the effects, but sometimes it is necessary to include an additional environmental seal.

The duplicity of seals can perform extremely well but has a fundamental problem of packaging. Two gaskets require a large amount of volume, particularly if one uses two ‘O’ ring grooves.

T C Shielding has specifically developed “duo-extrusion” to offer a compact, space efficient gasket. The duo-extrusion comprises two materials with a vulcanised seamed joint. One component is conductive, providing an effective EMC gasket, the other component is an environmental seal in non-conductive silicone or fluorosilicone. The environmental component effectively protects the EMC gasket from external contaminants, including moisture, thus preventing galvanic corrosion

Materials used can be silver aluminium, silver copper or nickel graphite silicones for the conductive seal, and silicone or fluorosilicone for the non-conductive sealing element.

Summary of features:

The product is produced by continuous process and can be supplied in strip, roll or conductive vulcanised to form a jointed ring.

Developed to address the dual requirements of environmental sealing and high levels of AEMC shielding.

Eliminates the potential for galvanic corrosion associated with highly conductive materials when used with dissimilar metallic hardware.

‘DUO SEAL’ FROM T C SHIELDING - THE ULTIMATE PROTECTION

ITEM A : CONDUCTIVE R/F SEAL

ITEM B : NON-CONDUCTIVE SEAL

NOTES:

MAXIMUM SECTIONAL AREA = 5.13mm PER SECTION

ITEMS A AND B ARE CO-VULCANISED

DUO SEAL PART No. ES-XX-176

REKOMENDOWANE WYMIARY ROwka DLA DUO SEAL ES-XX-176

NOTES ON DUO SEAL REF: ES-XX-176

Non standard profiles that have been developed to suit specific customer applications for high spec RFI / IP applications.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent