EMC protection

Categories

- Conductive adhesives, EMC paints

- Shielding

- Cable shielding

- Display glass bonding

- EMC coatings for plastic surfaces

- IP environmental gaskets

- Microwave absorbers / EMC shielding mats

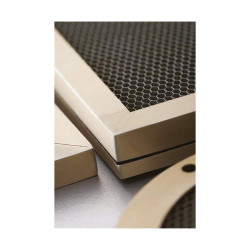

- EMC shielding for ventilation openings

- EMC conductive tapes

- Filtering

- EMC window shielding

- EPDM EMC edge gaskets

- EMC shielding of components on PCB boards

- EMC gaskets and contact pads

- EMC conductive elastomers

- EMC knitted mesh gaskets

- EMC foam gaskets

- Theory - products for electromagnetic protection

| Image | View the product | No. Manufacturer | ||||

|---|---|---|---|---|---|---|

| -- |

|

P & P Technology | Panele ekranujące wentylacyjne/plastry miodu - seria VH | SEE IT | Panele ekranujące wentylacyjne/plastry miodu - seria VH 25885 | On Order |

| -- |

|

Kitagawa GmbH | COOLPROVIDE / EMPV4 | SEE IT | COOLPROVIDE / EMPV4 53169 | On Order |

| -- |

|

Kitagawa GmbH | COOLPROVIDE/EMPV5 | SEE IT | COOLPROVIDE/EMPV5 53170 | On Order |

| -- |

|

Kitagawa GmbH | SMARTPLY / FFS | SEE IT | SMARTPLY / FFS 53171 | On Order |

| -- |

|

Kitagawa GmbH | SMARTPLY / FFSW | SEE IT | SMARTPLY / FFSW 53174 | On Order |

| -- |

|

Kitagawa GmbH | SMARTPLY/FFSX-H | SEE IT | SMARTPLY/FFSX-H 53176 | On Order |

| -- |

|

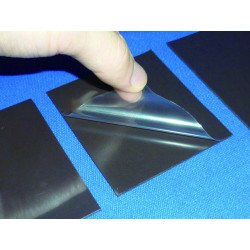

Kitagawa GmbH | Arkusz ekranujący GHz/GSS-HT | SEE IT | Arkusz ekranujący GHz/GSS-HT 53177 | On Order |

| -- |

|

Kitagawa GmbH | LESSMIRROR/LMR-RW | SEE IT | LESSMIRROR/LMR-RW 53178 | On Order |

| -- |

|

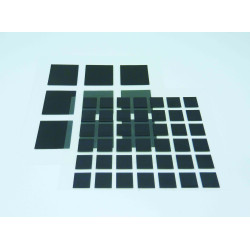

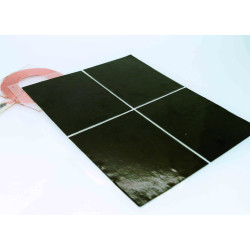

Kitagawa GmbH | Absorbery EMI/MAB | SEE IT | Absorbery EMI/MAB 53179 | On Order |

| -- |

|

Kitagawa GmbH | Magnefilm | SEE IT | Magnefilm 53180 | On Order |

| -- |

|

Kitagawa GmbH | Absorbery MG | SEE IT | Absorbery MG 53181 | On Order |

| -- |

|

Kitagawa GmbH | FG MESH/FGM | SEE IT | FG MESH/FGM 53182 | On Order |

| -- |

|

Kitagawa GmbH | FG STRAP/GFGST | SEE IT | FG STRAP/GFGST 53254 | On Order |

| -- |

|

KEMET | Mata absorbująca FX5 | SEE IT | Mata absorbująca FX5 34485 | On Order |

| -- |

|

KEMET | Mata absorbująca FG1 | SEE IT | Mata absorbująca FG1 34483 | On Order |

| -- |

|

P & P Technology | Kratki wentylacyjne z osłoną przeciwpyłową - seria VF | SEE IT | Kratki wentylacyjne z osłoną przeciwpyłową - seria VF 25886 | On Order |

| -- |

|

P & P Technology | Zestawy wentylacyjno-filtrujące - seria VB | SEE IT | Zestawy wentylacyjno-filtrujące - seria VB 25887 | On Order |

| -- |

|

OPTICAL FILTERS | Ekranowanie okien - wstęp | SEE IT | Ekranowanie okien - wstęp 25888 | On Order |

| -- |

|

OPTICAL FILTERS | Folia EmiClare MICROMESH | SEE IT | Folia EmiClare MICROMESH 25890 | On Order |

| -- |

|

TEMAS | Odmgławiacze | SEE IT | Odmgławiacze 25893 | On Order |

| -- |

|

Creavac | Pokrycia EMC powierzchni z tworzyw sztucznych | SEE IT | Pokrycia EMC powierzchni z tworzyw sztucznych 27205 | On Order |

| -- |

|

KEMET | Maty KEMET - przegląd | SEE IT | Maty KEMET - przegląd 34470 | On Order |

| -- |

|

KEMET | Mata absorbująca EFA | SEE IT | Mata absorbująca EFA 34472 | On Order |

| -- |

|

KEMET | Mata absorbująca EFF4 | SEE IT | Mata absorbująca EFF4 34475 | On Order |

EMC Protection in R&D: How to Ensure Electromagnetic Compatibility of Devices

In the era of digitalization and ubiquitous electronics, ensuring Electromagnetic Compatibility (EMC) has become one of the most important challenges for Research and Development (R&D) departments. EMC protection is a set of methods and solutions aimed at limiting the emission of electromagnetic interference from a device and ensuring its immunity to external interference. Failure in this area can lead to equipment malfunction, data loss, and even violation of legal regulations. Effective solutions in the field of shielding and filtering are crucial. They encompass both physical barriers and advanced Conductive EMC Elastomers, Conductive Adhesives, EMC Paints, and specialized EMC Gaskets and Contact Strips, which must be implemented early in the design phase.

Shielding and Absorption: The Foundation of Physical EMC Protection

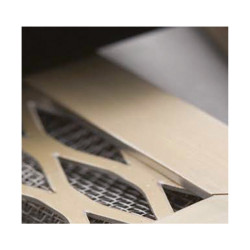

Physical shielding is the basic method of EMC protection, involving the construction of barriers from conductive materials to limit the propagation of the electromagnetic field. Various techniques are utilized in advanced R&D projects. EMC Coatings for Plastic Surfaces are applied, for example, using Conductive Adhesives, EMC Paints, which enable economical Shielding of plastic enclosures. Sealing gaps and openings with specialized products such as Braided Mesh EMC Gaskets, Foam EMC Gaskets, or EPDM EMC Edge Gaskets, often integrated with IP Environmental Seals, is also very important. To eliminate standing waves and reduce reflections, Microwave Absorbers / EMC Shielding Mats are placed inside the enclosures. Special solutions also include EMC Window Shielding and EMC Ventilation Hole Shielding to maintain the integrity of the shielding while preserving the device's functionality. Cable Shielding and Shielding of PCB Components EMC using miniature shields or Conductive EMC Tapes are standards in modern design.

Filtering and Sealing: Precise Signal Management and Shielding Continuity

Besides physical barriers, filtering – eliminating unwanted frequencies from power and signal lines – is an equally important aspect of EMC Protection. In the R&D phase, precise selection of filters is crucial for achieving compliance. Regarding seals and electrical connections, maintaining conductivity continuity is key. EMC Gaskets and Contact Strips are used for this purpose, providing a low-resistance connection between enclosure elements. Conductive EMC Elastomers are ideal for applications where both excellent conductivity and resistance to environmental conditions are required. Increasingly, Display Glass Bonding using conductive adhesives is also employed, which not only improves optical parameters but also ensures the continuity of the electromagnetic shielding of the panel.

Materials and Technologies: The Basis of Innovative EMC Protection in R&D

Success in the area of EMC protection depends on understanding and applying the latest material technologies. Conductive Adhesives, EMC Paints become essential for EMC Coating of Plastic Surfaces and creating conductive connections where traditional mechanical methods are impractical. Conductive EMC Tapes are a versatile tool for quick shielding, grounding, and sealing. As the operating frequency of devices increases, the importance of Microwave Absorbers / EMC Shielding Mats grows, as they effectively absorb electromagnetic energy instead of reflecting it. The ultimate goal of R&D design is to create a device that is reliable, efficient, and fully compliant with global electromagnetic compatibility standards, and proper EMC protection is essential for this.