Industrial Connectors | Han

Categories

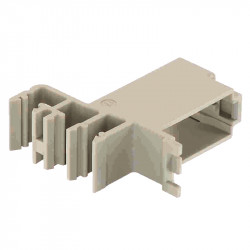

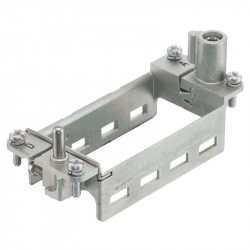

- Hoods/Housings variants

- Hoods/Housings - Inserts

- Clamping Elements for Inserts

- Han E Inserts

- Han ES Inserts

- Han ESS Inserts

- Han EE Inserts

- Han EEE Inserts

- Han HsB Inserts

- Han D Inserts

- Han DD Inserts

- Han A Inserts

- Han-Com Inserts

- Cartridges Han Q

- Han-Compact® Hoods/Housings

- Han-Power

- Han-Brid® Connectors

- Han-Modular® Modules

- Contacts

- Han-Modular® Compact

- Han-Modular® Accessories

- Han-Modular® Hinged frames

- Han-Snap

- Cable Entry Protection for Metric Cable Entries

- Hoods with Metric Cable Entries

- Housings with Metric Cable Entries

- Hoods/Housings with Metric Cable Entries for special applications

- Tools

Han Industrial Connectors: A Reliable Standard for Industry 4.0

Genesis and significance of the Han standard

Han® industrial connectors (Harting) are an international standard in connection technology, recognised worldwide as a synonym for durability, flexibility, and reliability in the toughest industrial conditions. Since their inception, they have become the fundamental interface for machines, production equipment, and automation systems, enabling fast, safe, and modular connections. Their main advantage is the ability to transmit both power supply, control signals, and data, and in hybrid variants, even media such as compressed air, all within one compact housing. This versatility is crucial in the era of Industry 4.0, where modularity and minimizing downtime are essential.

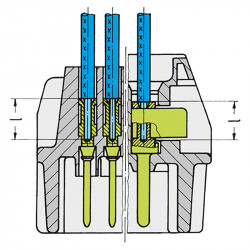

Robust construction and durability features

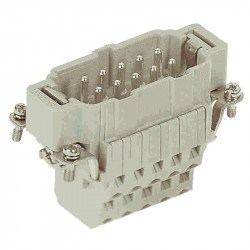

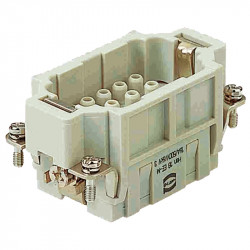

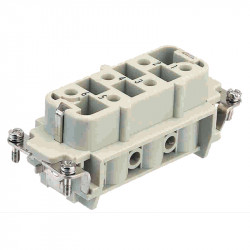

Han connectors are designed to operate in environments where ordinary electrical connectors would fail. These elements consist of three basic parts: the housing, the inserts (male and female), and the contacts (pins). The housings, often made of durable aluminium die-casting or specialized, halogen-free plastics (e.g., the Han-Eco series), provide a high degree of protection, typically ranging from IP65 to IP68, which effectively shields the connection from dust, moisture, water, and even chemicals. Their design also guarantees resistance to strong vibrations and mechanical stress. The availability of various cable termination techniques, such as screw, spring, PUSH IN clamps, or crimp pins, allows for optimal adaptation to the specifics of installation and the required vibration resistance.

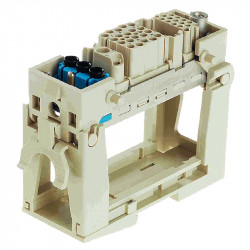

Han-Modular Modularity: Integration and space saving

A key engineering achievement in the Han connector family is the Han-Modular® system. It enables users to create individual solutions by combining various functional modules (e.g., power modules, signal modules, fibre optic, and pneumatic modules) in a single standard housing. This innovation significantly simplifies wiring, reduces the number of required interfaces, and, most importantly, saves up to 50% of space in control cabinets and machines. Thanks to Han-Modular®, in the event of a fault or the need for configuration change, only the damaged module can be replaced, not the entire wiring, which drastically shortens downtime and reduces maintenance costs.

Wide range of applications in key industries

Due to their versatility (e.g., miniature Han 1A, compact Han-Compact, or high-current Han Power), Han connectors have found applications in almost every industrial sector:

- Machine Building and Robotics: They enable quick replacement of modules, drives (Han Drive series), and easy connection of control systems.

- Energy: Used in wind turbines, photovoltaic installations, and for reliable power distribution.

- Rail Transport (Railway): They meet strict industry standards (e.g., EN 50155), making them ideal for use in door systems, lighting, and displays due to their vibration resistance and compact dimensions.

- Industrial Automation: Used to ensure safe access to control systems without the need to open the cabinet (e.g., the Han-Port series).

Their high standard of protection and resistance to disconnection makes them indispensable where normal electrical connections would be compromised.