Category

Photos are for informational purposes only. View product specification

please use latin characters

Description of the hygrostat

The humidity measuring element, produced by Galltec under the name Polyga®, consists of several synthetic

fabric bands each with 90 individual fibres with a diameter of 3μm. A special process gives the fibre

hygros-copic properties. The measuring element absorbs and desorbs humidity. The swelling effect, which

is predominantly in a lengthways direction, is carried via a suitable lever system to a microswitch with an

extremely small switching path. The measuring element reacts quickly and precisely to the change in air

humidity. By adjusting the setpoint value control knob, the lever system is engaged so that when the set air

humidity is reached the microswitch is activated. The fan-shaped measuring element is accomodated

inside the housing and must be protected against coarse dust, dirt and water. The sensors are designed

for pressureless systems. The mounting position should be chosen such that condensed water cannot

get into the interior of the housing. Any mounting position is possible, preferably with ventilation slots across

the direction of wind.

Application

The hygrostat type HG Mini is used as an on-off controller to control the relative air humidity. It can be used to control air humidifiers and dehumidifiers in offices and computer rooms. Other areas of use are storage of foodstuffs and luxury foods, cooling rooms for fruit and vegetables, greenhouses for gardening use, the textile industry, the paper and printing industry, the film industry and hospitals. The hygrostats can be used almost

anywhere that air humidity has to be regulated or monitored. The room hygrostat HG Mini-i is designed so that the adjusting knob and the scale are inside the housing. This makes unauthorized manipulation by third parties more difficult.

| Technical Data: | |

| - scale range | 30...100 % rh |

| - measuring accuracy | ±3% |

| - nge of operationy | 35...100% rh |

| - switching difference (microswitch) ref. to 50%rh | ok. 4% rh |

| max | 250 VAC |

| - Max load | ||

| Resistive load | 5A 230VAC | |

| Max load for humidifying | 2A | |

| Max load for dehumidifying | 5A | |

| Inductive load* cosφ=0,8 | 0,2A 230VAC | |

| Inductive load* L/R=3ms | 1A 50VDC | |

| 0,5A 75VDC | ||

| - Min load | 100mA, 20VDC/AC | |

| - allowable ambient temperature | 0...60°C | |

| - medium temp. coefficient | -0.2%/K rel.to 20°C and 50%rh | |

| - allowable air speed | 15 m/s | |

| - half-life period at v=2m/sec | 1,2min | |

| - fixing | slots in housing base | |

| - mounting position | optional, preferably ventilation slots at right-angles to wind direction |

|

| - contacting | connecting terminal in the case | |

| - electromagnetic compatibility | ||

| Resistance | zg. EN 50 082-2 | |

| Emission | zg. EN 50 081-2 | |

| - housing | szary plastik | |

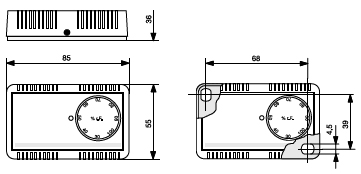

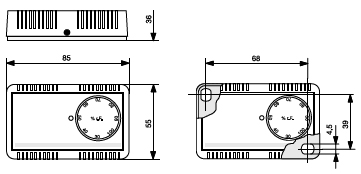

| - dimensions | 85x55x36mm | |

| - protective system | IP20 | |

| - weight | ok. 0,06 kg | |

| Type Survey | ||

|---|---|---|

| Type | Order no. | Type of contact |

| HG Mini | 42042017 | changeover contact: 1 x max. 5 A |

| HG Mini-i | 42042018 | changeover contact: 1 x max. 5 A with internal scale |

Fx: actual value of the relative humidity

Fw: setpoint value of the rel. humidiy set at the adjusting knob

Mounting

The hygrostat must not come into direct contact with water, e.g. splashed water when cleaning the climatic

chamber etc. The mounting location should be chosen so that a representative measurement of the air humidity can be guaranteed, i.e. the humidity readings at the mounting location should correspond to those in the room.

The hygrostat should be exposed to the flow of air.

| 10[°c] | 20[°c] | 30[°c] | 50[°c] | |

|---|---|---|---|---|

| 10%rh | ±0,7%rh | ±0,6%rh | ±0,6%rh | ±0,5%rh |

| 50%rh | ±3,5%rh | ±3,2%rh | ±3,0%rh | ±2,6%rh |

| 90%rh | ±6,3%rh | ±5,7%rh | ±5,4%rh | ±4,6%rh |

It is thus of extreme importance that the temperature is constant for measurements of the relative air humidity. The air must be homogenous.

Are you interested in this product? Do you need additional information or individual pricing?

Description of the hygrostat

The humidity measuring element, produced by Galltec under the name Polyga®, consists of several synthetic

fabric bands each with 90 individual fibres with a diameter of 3μm. A special process gives the fibre

hygros-copic properties. The measuring element absorbs and desorbs humidity. The swelling effect, which

is predominantly in a lengthways direction, is carried via a suitable lever system to a microswitch with an

extremely small switching path. The measuring element reacts quickly and precisely to the change in air

humidity. By adjusting the setpoint value control knob, the lever system is engaged so that when the set air

humidity is reached the microswitch is activated. The fan-shaped measuring element is accomodated

inside the housing and must be protected against coarse dust, dirt and water. The sensors are designed

for pressureless systems. The mounting position should be chosen such that condensed water cannot

get into the interior of the housing. Any mounting position is possible, preferably with ventilation slots across

the direction of wind.

Application

The hygrostat type HG Mini is used as an on-off controller to control the relative air humidity. It can be used to control air humidifiers and dehumidifiers in offices and computer rooms. Other areas of use are storage of foodstuffs and luxury foods, cooling rooms for fruit and vegetables, greenhouses for gardening use, the textile industry, the paper and printing industry, the film industry and hospitals. The hygrostats can be used almost

anywhere that air humidity has to be regulated or monitored. The room hygrostat HG Mini-i is designed so that the adjusting knob and the scale are inside the housing. This makes unauthorized manipulation by third parties more difficult.

| Technical Data: | |

| - scale range | 30...100 % rh |

| - measuring accuracy | ±3% |

| - nge of operationy | 35...100% rh |

| - switching difference (microswitch) ref. to 50%rh | ok. 4% rh |

| max | 250 VAC |

| - Max load | ||

| Resistive load | 5A 230VAC | |

| Max load for humidifying | 2A | |

| Max load for dehumidifying | 5A | |

| Inductive load* cosφ=0,8 | 0,2A 230VAC | |

| Inductive load* L/R=3ms | 1A 50VDC | |

| 0,5A 75VDC | ||

| - Min load | 100mA, 20VDC/AC | |

| - allowable ambient temperature | 0...60°C | |

| - medium temp. coefficient | -0.2%/K rel.to 20°C and 50%rh | |

| - allowable air speed | 15 m/s | |

| - half-life period at v=2m/sec | 1,2min | |

| - fixing | slots in housing base | |

| - mounting position | optional, preferably ventilation slots at right-angles to wind direction |

|

| - contacting | connecting terminal in the case | |

| - electromagnetic compatibility | ||

| Resistance | zg. EN 50 082-2 | |

| Emission | zg. EN 50 081-2 | |

| - housing | szary plastik | |

| - dimensions | 85x55x36mm | |

| - protective system | IP20 | |

| - weight | ok. 0,06 kg | |

| Type Survey | ||

|---|---|---|

| Type | Order no. | Type of contact |

| HG Mini | 42042017 | changeover contact: 1 x max. 5 A |

| HG Mini-i | 42042018 | changeover contact: 1 x max. 5 A with internal scale |

Fx: actual value of the relative humidity

Fw: setpoint value of the rel. humidiy set at the adjusting knob

Mounting

The hygrostat must not come into direct contact with water, e.g. splashed water when cleaning the climatic

chamber etc. The mounting location should be chosen so that a representative measurement of the air humidity can be guaranteed, i.e. the humidity readings at the mounting location should correspond to those in the room.

The hygrostat should be exposed to the flow of air.

| 10[°c] | 20[°c] | 30[°c] | 50[°c] | |

|---|---|---|---|---|

| 10%rh | ±0,7%rh | ±0,6%rh | ±0,6%rh | ±0,5%rh |

| 50%rh | ±3,5%rh | ±3,2%rh | ±3,0%rh | ±2,6%rh |

| 90%rh | ±6,3%rh | ±5,7%rh | ±5,4%rh | ±4,6%rh |

It is thus of extreme importance that the temperature is constant for measurements of the relative air humidity. The air must be homogenous.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent