Category

Photos are for informational purposes only. View product specification

please use latin characters

DACPOL Sp. z o.o. has been engaged in sales, manufacturing, consulting, and service activities for over 27 years.

We specialize in comprehensive supply of components for: POWER ELECTRONICS, ELECTRONICS, INDUSTRIAL AUTOMATION, ELECTRONICS, ENERGY, and EX ZONES.

We also design and manufacture power units, induction heating, and manufacture and service industrial measurement devices.

We consistently implement a comprehensive customer service strategy through a wide range of products, the knowledge and experience of our engineers, and efficient logistics. We closely monitor the development of new technologies, striving to ensure access to market innovations.

DACPOL has expanded its product solutions designed for use in potentially explosive atmospheres, such as zones 0, 1, or 2 for gases, and zones 20, 21, or 22 for dust.

Our Ex product range includes equipment compliant with the ATEX Directive 2014/34/EU. The technical team will help you choose the right solutions for your individual needs.

EX Electrical Engineering

The EX PRODUCTS catalog includes selected products that are regularly available. Thanks to our experience, we offer professional assistance and advice in selecting the optimal solution.

We offer products designed for use in diverse environments where explosive atmospheres can be generated in zones 0, 1, or 2 for gases, as well as zones 20, 21, or 22 for dust. In our catalog, you will find equipment compliant with the ATEX Directive 2014/34/EU (ATEX 114).

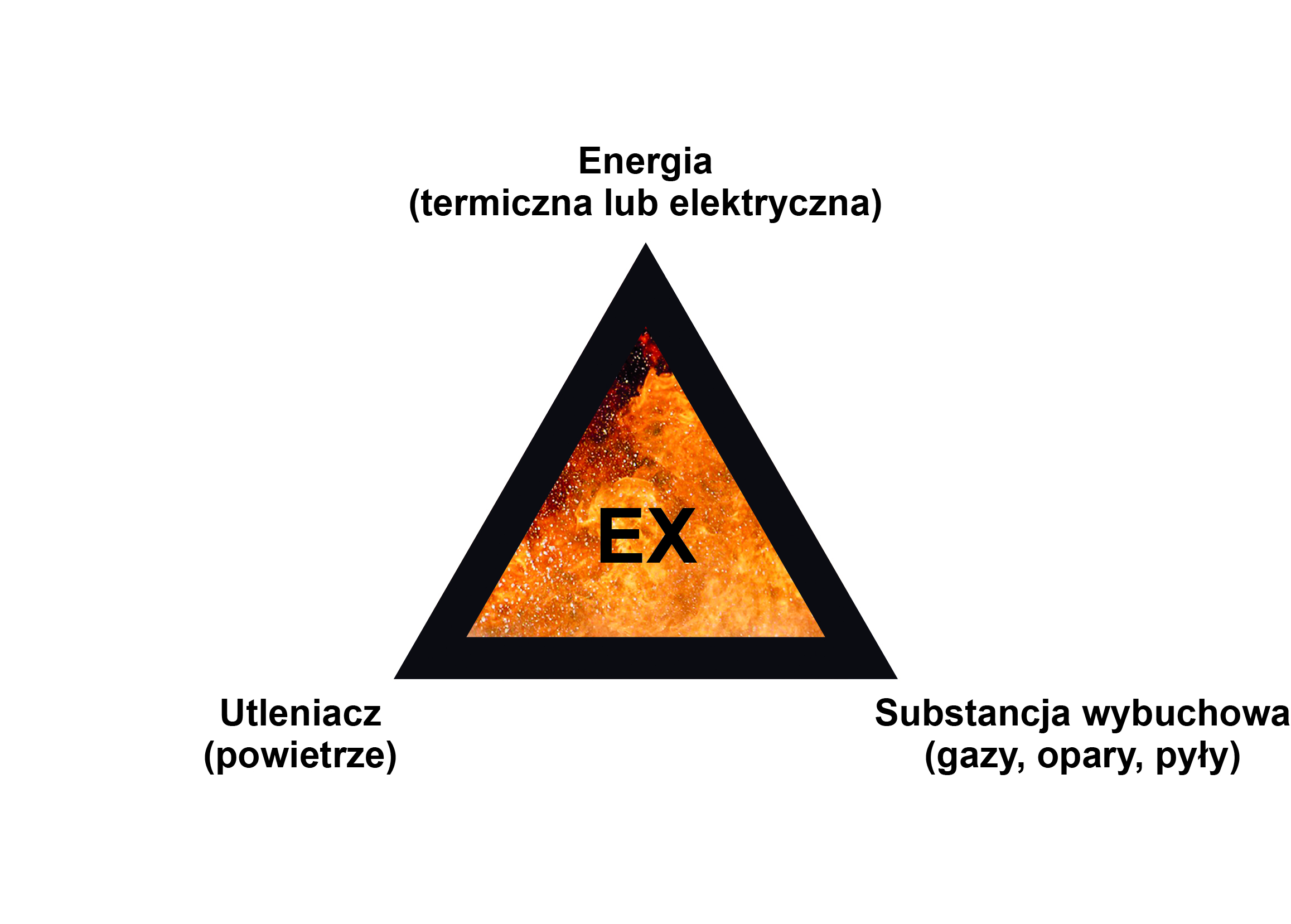

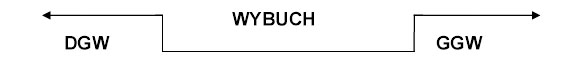

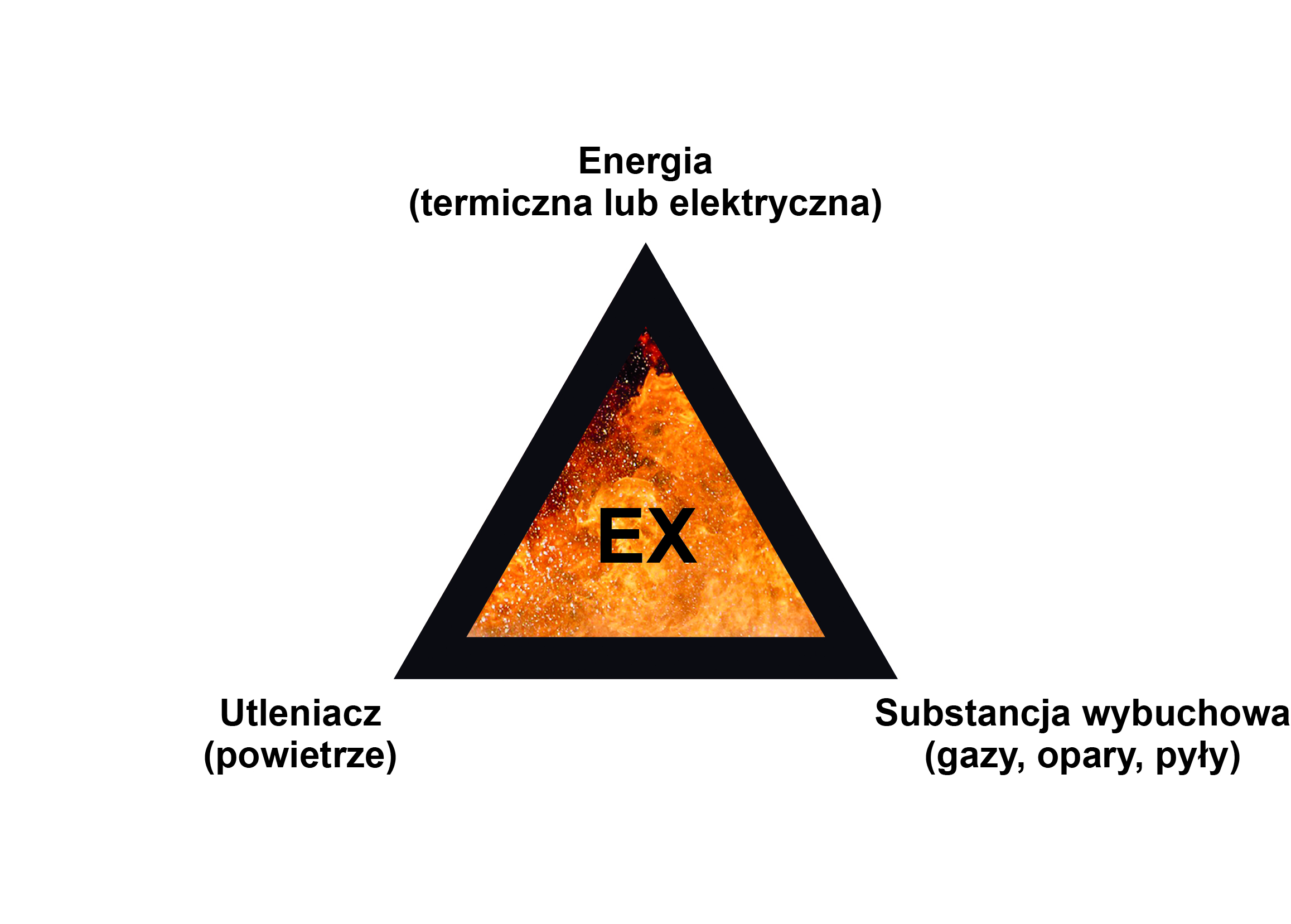

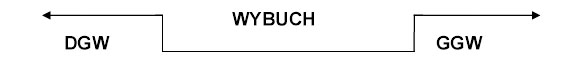

GAS EXPLOSION HAZARD ZONE – an area in which a mixture of flammable substances with air or other oxidizing gases may occur, with a concentration between the lower and upper explosion limits. Explosion hazard zones are workplaces where explosive atmospheres may occur. They are classified according to the division into explosion hazard zones, in accordance with § 5.1 of the Regulation of the Minister of Economy of July 8, 2010. "On the minimum requirements for occupational health and safety related to the possibility of an explosive atmosphere occurring in the workplace" (Journal of Laws of 2010, No. 138, item 931).

| Gas | % gas in air | |

|---|---|---|

| DGW | GGW | |

| Hydrogen | 4.1 | 74.2 |

| Carbon monoxide | 12.5 | 74.2 |

| Methane | 5.3 | 14 |

| Ethane | 3,2 | 12.5 |

| Propane | 2.4 | 9.5 |

| Butane | 8.4 | |

| Acetylene | 2.5 | 80 |

| Gas | 5,6 | 31 |

| Water gas | 6.2 | 72 |

| Natural Gas | 4.5 | 17 |

| City gas | 32 | 74 |

Autoignition temperature is the lowest temperature at which a flammable substance ignites upon contact with a hot surface or as a result of thermal radiation from that surface (without the participation of an external flame or spark). Gases and liquid vapors with an autoignition temperature below 85°C are considered autoignitable at room temperature.

| Autoignition temperature [°C] | Temperature class | Example substance |

|---|---|---|

| > 450 | T1 | Hydrogen, carbon monoxide, ammonia |

| > 300 - 450 | T2 | Acetylene, n-butane, ethylene oxide |

| > 200 - 300 | T3 | N-octane, turpentine, acrolein |

| > 135 - 200 | T4 | Acetaldehyde, diethyl ether |

| > 100 - 135 | T5 | Carbon disulfide |

| > 85 - 100 | T6 | Phosphine |

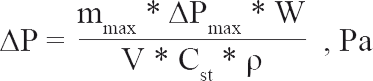

| Group I: | Methane in underground mine workings |

| Group II: | Gas, mists, vapors IIA – propane group (260 µJ) (122 gases and vapors, e.g., acetone, methyl and ethyl alcohol) IIB – ethylene group (95 µJ) (27 gases and vapors, e.g., ethylene, hydrogen sulfide) IIC – hydrogen group (18 µJ) /> (4 gases: acetylene, hydrogen, hydrazine, carbon disulfide) |

| Group III: | dust and other IIIA – explosive flocs IIIB – non-conductive dust IIIC – conductive dust |

Primary ignition sources may be:

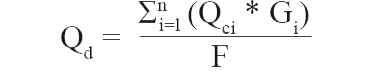

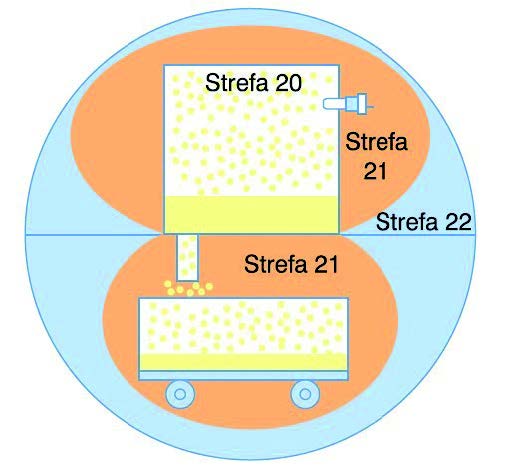

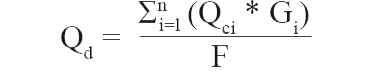

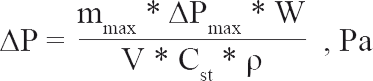

| Fire load density | Increase in pressure in a room caused by an explosion involving flammable gases or vapors |

||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

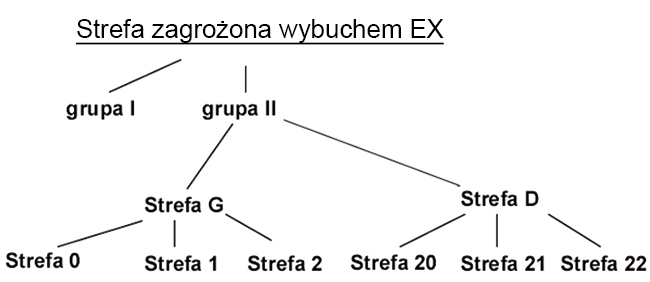

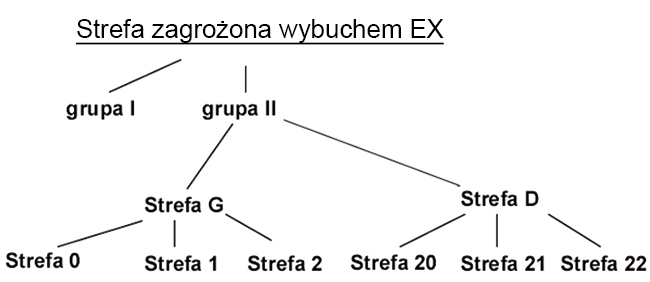

Zone G – gases, mists, vapors

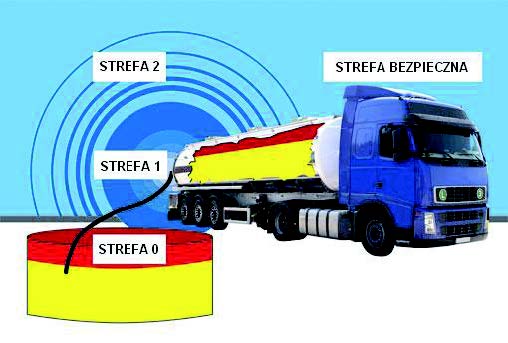

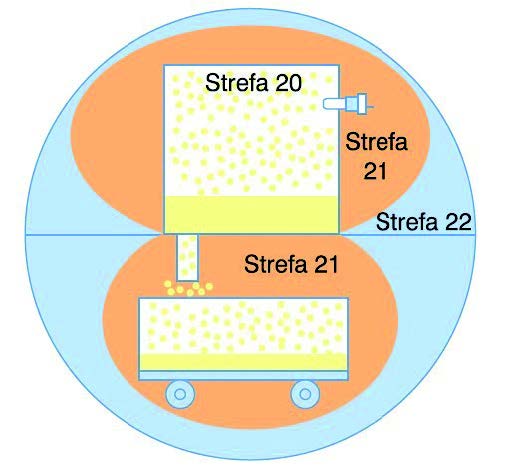

Zone D – dust

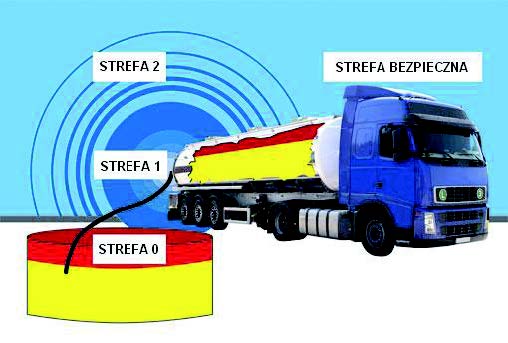

Zone 0 – an explosive atmosphere occurs continuously and persists for a long time

Zone 1 – an explosive atmosphere occurs sporadically

Zone 2 – an explosive atmosphere does not occur during normal operation, and if it does occur, it persists for a short time.

EQUIPMENT CATEGORY 1 – these devices provide a very high level of safety and allow for continuous operation where an explosive atmosphere is constantly present => zone "0"

EQUIPMENT CATEGORY 2 – these devices provide a high level of protection => Zone "1"

CATEGORY 3 DEVICES – these devices provide a normal level of protection => Zone "2"

| Explosion hazard zone | Explosion hazard zone | Device category |

|---|---|---|

| 0 | 20 | 1 |

| 1 | 21 | 2 |

| 2 | 22 | 3 |

|

|

| Protection type for zones 0+1+2 | |||

|---|---|---|---|

| Protection type | Standard | Description | Zone |

| EX d | 60079-1 | Flameproof construction | 1 and 2 |

| EX p | 60079-2 | Positive pressure gas shield | 1 and 2 |

| EX q | 60079-5 | Sand cover | 1 and 2 |

| EX o | 60079-6 | Oil cover | 1 and 2 |

| EX e | 60079-7 | Reinforced structure | 1 and 2 |

| EX i | 60079-11 | Intrinsically safe | 0, 1 and 2 |

| EX n | 60079-15 | Construction of "EX n" devices | 2 |

| EX m | 60079-18 | Device encapsulated with 'm' insulating mass | 1 and 2 |

| Protection type for zones 0+1+2 | |||

| EX tD | 61241-1 | Protection by enclosure | 21 and 22 |

| EX pD | 61241-4 | Protection under pressure | 21 and 22 |

| EX iD | 61241-11 | Intrinsically safe | 20, 21 and 22 |

| EX m.D | 61241-18 | Device encapsulated with 'm' insulating mass | 20, 21 and 22 |

Are you interested in this product? Do you need additional information or individual pricing?

DACPOL Sp. z o.o. has been engaged in sales, manufacturing, consulting, and service activities for over 27 years.

We specialize in comprehensive supply of components for: POWER ELECTRONICS, ELECTRONICS, INDUSTRIAL AUTOMATION, ELECTRONICS, ENERGY, and EX ZONES.

We also design and manufacture power units, induction heating, and manufacture and service industrial measurement devices.

We consistently implement a comprehensive customer service strategy through a wide range of products, the knowledge and experience of our engineers, and efficient logistics. We closely monitor the development of new technologies, striving to ensure access to market innovations.

DACPOL has expanded its product solutions designed for use in potentially explosive atmospheres, such as zones 0, 1, or 2 for gases, and zones 20, 21, or 22 for dust.

Our Ex product range includes equipment compliant with the ATEX Directive 2014/34/EU. The technical team will help you choose the right solutions for your individual needs.

EX Electrical Engineering

The EX PRODUCTS catalog includes selected products that are regularly available. Thanks to our experience, we offer professional assistance and advice in selecting the optimal solution.

We offer products designed for use in diverse environments where explosive atmospheres can be generated in zones 0, 1, or 2 for gases, as well as zones 20, 21, or 22 for dust. In our catalog, you will find equipment compliant with the ATEX Directive 2014/34/EU (ATEX 114).

GAS EXPLOSION HAZARD ZONE – an area in which a mixture of flammable substances with air or other oxidizing gases may occur, with a concentration between the lower and upper explosion limits. Explosion hazard zones are workplaces where explosive atmospheres may occur. They are classified according to the division into explosion hazard zones, in accordance with § 5.1 of the Regulation of the Minister of Economy of July 8, 2010. "On the minimum requirements for occupational health and safety related to the possibility of an explosive atmosphere occurring in the workplace" (Journal of Laws of 2010, No. 138, item 931).

| Gas | % gas in air | |

|---|---|---|

| DGW | GGW | |

| Hydrogen | 4.1 | 74.2 |

| Carbon monoxide | 12.5 | 74.2 |

| Methane | 5.3 | 14 |

| Ethane | 3,2 | 12.5 |

| Propane | 2.4 | 9.5 |

| Butane | 8.4 | |

| Acetylene | 2.5 | 80 |

| Gas | 5,6 | 31 |

| Water gas | 6.2 | 72 |

| Natural Gas | 4.5 | 17 |

| City gas | 32 | 74 |

Autoignition temperature is the lowest temperature at which a flammable substance ignites upon contact with a hot surface or as a result of thermal radiation from that surface (without the participation of an external flame or spark). Gases and liquid vapors with an autoignition temperature below 85°C are considered autoignitable at room temperature.

| Autoignition temperature [°C] | Temperature class | Example substance |

|---|---|---|

| > 450 | T1 | Hydrogen, carbon monoxide, ammonia |

| > 300 - 450 | T2 | Acetylene, n-butane, ethylene oxide |

| > 200 - 300 | T3 | N-octane, turpentine, acrolein |

| > 135 - 200 | T4 | Acetaldehyde, diethyl ether |

| > 100 - 135 | T5 | Carbon disulfide |

| > 85 - 100 | T6 | Phosphine |

| Group I: | Methane in underground mine workings |

| Group II: | Gas, mists, vapors IIA – propane group (260 µJ) (122 gases and vapors, e.g., acetone, methyl and ethyl alcohol) IIB – ethylene group (95 µJ) (27 gases and vapors, e.g., ethylene, hydrogen sulfide) IIC – hydrogen group (18 µJ) /> (4 gases: acetylene, hydrogen, hydrazine, carbon disulfide) |

| Group III: | dust and other IIIA – explosive flocs IIIB – non-conductive dust IIIC – conductive dust |

Primary ignition sources may be:

| Fire load density | Increase in pressure in a room caused by an explosion involving flammable gases or vapors |

||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

Zone G – gases, mists, vapors

Zone D – dust

Zone 0 – an explosive atmosphere occurs continuously and persists for a long time

Zone 1 – an explosive atmosphere occurs sporadically

Zone 2 – an explosive atmosphere does not occur during normal operation, and if it does occur, it persists for a short time.

EQUIPMENT CATEGORY 1 – these devices provide a very high level of safety and allow for continuous operation where an explosive atmosphere is constantly present => zone "0"

EQUIPMENT CATEGORY 2 – these devices provide a high level of protection => Zone "1"

CATEGORY 3 DEVICES – these devices provide a normal level of protection => Zone "2"

| Explosion hazard zone | Explosion hazard zone | Device category |

|---|---|---|

| 0 | 20 | 1 |

| 1 | 21 | 2 |

| 2 | 22 | 3 |

|

|

| Protection type for zones 0+1+2 | |||

|---|---|---|---|

| Protection type | Standard | Description | Zone |

| EX d | 60079-1 | Flameproof construction | 1 and 2 |

| EX p | 60079-2 | Positive pressure gas shield | 1 and 2 |

| EX q | 60079-5 | Sand cover | 1 and 2 |

| EX o | 60079-6 | Oil cover | 1 and 2 |

| EX e | 60079-7 | Reinforced structure | 1 and 2 |

| EX i | 60079-11 | Intrinsically safe | 0, 1 and 2 |

| EX n | 60079-15 | Construction of "EX n" devices | 2 |

| EX m | 60079-18 | Device encapsulated with 'm' insulating mass | 1 and 2 |

| Protection type for zones 0+1+2 | |||

| EX tD | 61241-1 | Protection by enclosure | 21 and 22 |

| EX pD | 61241-4 | Protection under pressure | 21 and 22 |

| EX iD | 61241-11 | Intrinsically safe | 20, 21 and 22 |

| EX m.D | 61241-18 | Device encapsulated with 'm' insulating mass | 20, 21 and 22 |

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent