Category

Photos are for informational purposes only. View product specification

please use latin characters

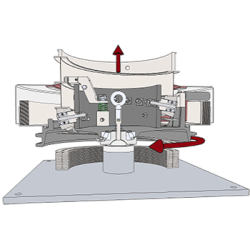

Spiralift is an innovative solution for lifting, hoisting, and integration with stage and industrial systems.

Compact design

Minimum height when folded – ideal for locations with limited installation space.

Quick assembly

Can be installed on any solid load-bearing surface, such as concrete or steel – without the need for special foundations.

Minimum maintenance requirements

Thanks to the use of stainless steel belt and the high mechanical efficiency of the system.

Low energy consumption

Relatively low-power motors are sufficient – saving energy and operating costs.

Modular design

Easily adaptable to various platforms, stages, and building architecture.

Possibility Synchronization

Multiple Spiralift units can work together within a single drive system – ideal for large and complex applications.

Adjustable Lift

Adjustable lift table that can be placed directly on a steel conveyor. Allows for temporary support of the car body during assembly, which simplifies the work of operators, improves ergonomics, and helps maintain production flow without downtime.

Spiralift Lifting Table

A lighter, cleaner, and energy-efficient alternative to classic scissor lift tables Hydraulic.

Modern AGVs equipped with Spiralift lifts are the ideal solution for automating load transport in warehouses and production plants. They allow for precise lifting and lowering of pallets, containers, or components.

Support for body and component assembly

On classic production lines, Spiralift can function as an adjustable workstation. Allows operators to adjust the platform height to the assembly stage, improving ergonomics and work safety.

Fully automated lifting in continuous systems

On modern, fully automated lines, Spiralift integrates directly with conveyors and robots, enabling precise positioning of large components.

Spiralift is a lifting system hidden beneath the bottom that changes the pool depth in 15 minutes – from from a shower tray to a full-size track.

Spiralift Technology It is used in modern stage and architectural installations. Thanks to its compact, hydraulic-free design, these systems allow for quiet and smooth adjustment of the stage, floor, or platform height – with millimeter precision. Spiralift is suitable for both theaters and multi-purpose spaces.

Are you interested in this product? Do you need additional information or individual pricing?

Spiralift is an innovative solution for lifting, hoisting, and integration with stage and industrial systems.

Compact design

Minimum height when folded – ideal for locations with limited installation space.

Quick assembly

Can be installed on any solid load-bearing surface, such as concrete or steel – without the need for special foundations.

Minimum maintenance requirements

Thanks to the use of stainless steel belt and the high mechanical efficiency of the system.

Low energy consumption

Relatively low-power motors are sufficient – saving energy and operating costs.

Modular design

Easily adaptable to various platforms, stages, and building architecture.

Possibility Synchronization

Multiple Spiralift units can work together within a single drive system – ideal for large and complex applications.

Adjustable Lift

Adjustable lift table that can be placed directly on a steel conveyor. Allows for temporary support of the car body during assembly, which simplifies the work of operators, improves ergonomics, and helps maintain production flow without downtime.

Spiralift Lifting Table

A lighter, cleaner, and energy-efficient alternative to classic scissor lift tables Hydraulic.

Modern AGVs equipped with Spiralift lifts are the ideal solution for automating load transport in warehouses and production plants. They allow for precise lifting and lowering of pallets, containers, or components.

Support for body and component assembly

On classic production lines, Spiralift can function as an adjustable workstation. Allows operators to adjust the platform height to the assembly stage, improving ergonomics and work safety.

Fully automated lifting in continuous systems

On modern, fully automated lines, Spiralift integrates directly with conveyors and robots, enabling precise positioning of large components.

Spiralift is a lifting system hidden beneath the bottom that changes the pool depth in 15 minutes – from from a shower tray to a full-size track.

Spiralift Technology It is used in modern stage and architectural installations. Thanks to its compact, hydraulic-free design, these systems allow for quiet and smooth adjustment of the stage, floor, or platform height – with millimeter precision. Spiralift is suitable for both theaters and multi-purpose spaces.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent