Category

Photos are for informational purposes only. View product specification

please use latin characters

Conductive paints and coatings improve the protection of electronic equipment against electromagnetic interference (EMI). They form a durable layer that conducts electricity and can even prevent the buildup of static electricity. Designing this into the equipment housing is also crucial to ensure proper shielding. Nowadays, plastic is commonly used because it is lightweight, portable, attractive, and inexpensive. However, plastic does not protect equipment from interference, which means it can be damaged. "Metallization" is a method of applying a metallic coating to plastic that provides EMI protection and ensures that the equipment meets EMC requirements. Conductive colloids are metal-loaded resin-based materials that are sprayed on. Metal serves as a reflective or absorbing barrier to RFI and EMI and typically comes in the form of flake or granule layers. Paints with various powder fillers and resin-elastomer binders are available to suit most applications and finishes. The most popular materials include nickel, copper, copper hybrid, silver hybrid, and silver.

The LS1001-CN-S coating is a product developed using specially prepared nickel granules and conductive resins, forming a conductive layer on plastic, resin, and metal substrates for a wide range of products.

The LS2001-CC-C coating is a product developed using specially prepared silver-coated copper particles and conductive resins, forming a conductive layer on plastic, resin, and metal substrates for a wide range of products.

The LS3001 coating is a product developed using specially prepared silver-coated copper particles and conductive resins, forming a highly conductive layer on plastic, resin, and metal substrates for a wide range of products.

The LS5001-CS-C coating is based on specially prepared silver flakes and conductive resins, forming a conductive layer on plastic, resin, and metal substrates for a wide range of products.

Are you interested in this product? Do you need additional information or individual pricing?

Conductive paints and coatings improve the protection of electronic equipment against electromagnetic interference (EMI). They form a durable layer that conducts electricity and can even prevent the buildup of static electricity. Designing this into the equipment housing is also crucial to ensure proper shielding. Nowadays, plastic is commonly used because it is lightweight, portable, attractive, and inexpensive. However, plastic does not protect equipment from interference, which means it can be damaged. "Metallization" is a method of applying a metallic coating to plastic that provides EMI protection and ensures that the equipment meets EMC requirements. Conductive colloids are metal-loaded resin-based materials that are sprayed on. Metal serves as a reflective or absorbing barrier to RFI and EMI and typically comes in the form of flake or granule layers. Paints with various powder fillers and resin-elastomer binders are available to suit most applications and finishes. The most popular materials include nickel, copper, copper hybrid, silver hybrid, and silver.

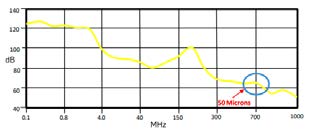

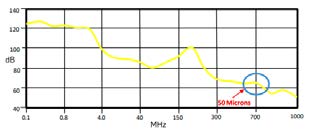

The LS1001-CN-S coating is a product developed using specially prepared nickel granules and conductive resins, forming a conductive layer on plastic, resin, and metal substrates for a wide range of products.

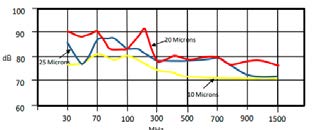

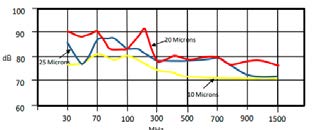

The LS2001-CC-C coating is a product developed using specially prepared silver-coated copper particles and conductive resins, forming a conductive layer on plastic, resin, and metal substrates for a wide range of products.

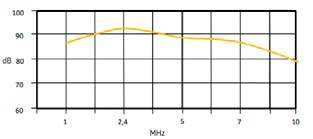

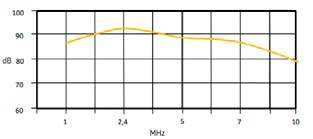

The LS3001 coating is a product developed using specially prepared silver-coated copper particles and conductive resins, forming a highly conductive layer on plastic, resin, and metal substrates for a wide range of products.

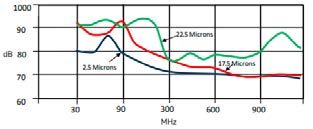

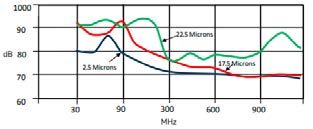

The LS5001-CS-C coating is based on specially prepared silver flakes and conductive resins, forming a conductive layer on plastic, resin, and metal substrates for a wide range of products.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent