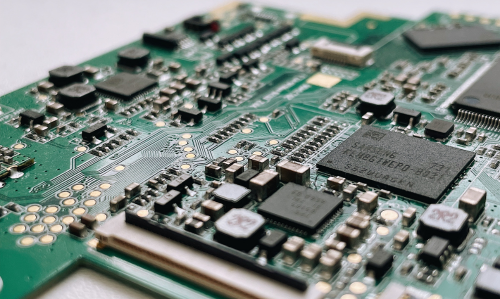

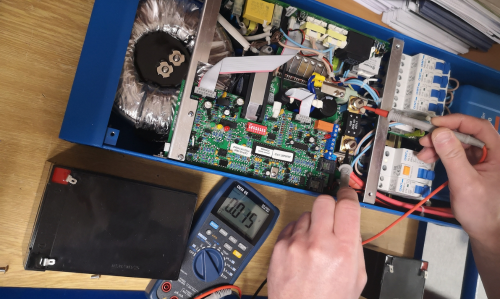

EMI (Electromagnetic Interference) refers to unwanted signals that can disrupt the operation of electronic devices. As electronics become smaller and more complex, they also become more susceptible to such interference. EMI can lead to errors, instability, or even system failures. That’s why proper circuit design — including electromagnetic shielding at the PCB level — is so important. This article explains how EMI shielding works, what materials to use, and how to avoid common design pitfalls.

Suppliers

View all suppliersProduct Categories

View all categoriesLatest posts

-

Navitas introduces the latest SiCPAK™ power modules – a new standard of reliability and performance at high temperaturesRead more

Navitas Semiconductor, a leader in GaN and SiC technology, has introduced new 1200V SiCPAK™ power modules with epoxy insulation, offering five times better thermal resistance than traditional solutions. Thanks to proprietary GeneSiC™ SiC MOSFET technology, the new modules ensure lower power loss, higher reliability, and resilience in extreme conditions. They are designed for applications such as EV chargers, industrial drives, UPS systems, and photovoltaic installations. As a pioneer in next-generation semiconductors, Navitas also offers the world’s first 20-year warranty on GaNFast™ devices.

-

Intrinsic Safety - Basic Guidelines for ProceedingRead more

This article explains the process of intrinsic safety verification, covering key aspects such as zone classification, device groups, temperature classes, and cable requirements in intrinsically safe circuits. It provides five essential tips for selecting the right equipment, ensuring proper documentation, and meeting safety standards like IEC 60079-14 for explosive atmospheres.

![Components for Hazardous Areas & Explosive Atmospheres [Ex]](https://www.dacpol.eu/c/6823-catsmal_default/components-for-hazardous-areas-ex-59693.jpg)