Menu

-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- TEMPEST emission revealing filters

- Surge arrester

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

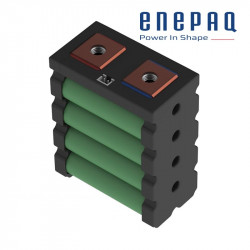

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Spiralift Lifts

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Cable feedthroughs and couplers

- Litz wires

-

Cables for extreme applications

- Extension and Compensation cables

- Thermocouple cables

- Connection cables for PT sensors

- Multi-conductor wires (temp. -60C to +1400C)

- Medium voltage cables

- Ignition wires

- Heating cables

- Single conductor cables (temp. -60C to +450C)

- Railway cables

- Heating cables Ex

- Cables for the defense industry

- Go to the subcategory

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Steel Braids

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

Blog navigation

Industrial batteries and how to manage their operation

A battery is a type of galvanic cell that converts chemical energy directly into electrical energy. The special features of batteries are their rechargeability and ability to store electrical energy.

This makes them an integral part of uninterruptible power systems - systems that maintain a constant power supply even in the event of a power outage or grid disturbance.Despite their advantages and wide industrial applications, batteries are also a bit of a problem in the topic of uninterruptible power supply because they have limited capacity, life span and are sensitive to various operating conditions such as temperature, which can affect their premature loss of capacity or malfunction.

In order to increase the efficiency and protect the batteries from harsh operating conditions, so-called battery management systems are used. Rapid technological development of such systems affects the efficiency of battery operation, including the efficiency of electricity conversion, and allows to monitor the operation of galvanic cells in real time, in effect balancing the slow development of chemical power source technology.

TYPES OF INDUSTRIAL BATTERIES

The most common type of industrial cells are lead-acid versions. They provide great comfort of use, because they do not require maintenance of the electrolyte and can work in any position due to the lack of liquid electrolyte. The main representatives are sealed types SLA/VRLA, often called maintenance-free batteries. Thanks to sealed casings, they do not emit acid fumes and harmful gases during normal operation, so they are harmless to the environment and safe to use.

Maintenance-free SLA batteries are made with two technologies that differ in the way the electrolyte binds:

• AGM batteries (Absorbed Glass Mat) – all of the electrolyte is absorbed by the highly porous glass fibers between the separators located between the lead plates of the battery.

• Gel batteries – the electrolyte is a gel mass due to the addition of silica SiO2.

AGM batteries have a higher terminal voltage and are able to run longer due to their lower internal resistance than gel batteries. Additionally, they have a higher capacity because in gel batteries part of the electrolyte is a gelling agent.

On the other hand, gel batteries provide better cell cooling and greater resistance to vibration and shock. Further advantages are the ability to regenerate after hours of short circuits and resistance to surges.

AGM technology is most commonly used in UPS for cyclic operation, while the gel version is ideal for buffer power supplies.

Li-ion batteries are another type of battery that is increasingly finding its way into specialized and industrial applications. The operation of Li-Ion batteries is based on chemical transformations that occur as positive ions pass through the electrolyte between the cathode and anode. The cathode is made of lithium compounds, while the anode is usually made of carbon materials.

The characteristics of such batteries are:

- Large capacity in a relatively small size;

- No memory effect (can be recharged at any time);

- Low cell weight;

- Environmentally friendly (no heavy metals, recyclable);

- Long service life;

- High energy density;

- Operating in a high operating temperature range.

BATTERY MANAGEMENT SYSTEMS

Through constant emphasis on the use of new technologies that perform significantly better and have a longer life than their predecessors, Li-Ion batteries are slowly replacing older solutions where their use will positively impact the performance of the end device.

In order to get the most out of their batteries, while ensuring that they are protected from the environmental conditions in which they operate, most companies utilize additional systems that support the operation of such batteries.

BMS (Battery Management Systems)

BMS are electronic control systems that monitor and regulate the charging and discharging of batteries. Characteristics monitored most commonly include detection of battery type, voltage, temperature, capacity, state of charge, power consumption, remaining run time, charge cycles, and more.

Battery management systems are designed to ensure that the remaining energy in the cells is optimally utilized. To increase battery life, BMS protects batteries from deep discharge and from surges that can result from fast charging and high discharge current. If you have multi-cell batteries, the BMS also provides a cell balancing function so that each cell in the battery has the same charging and discharging requirements.

There are many types of BMS systems available on the market. Battery management systems are best selected with the help of a specialist who, after determining the requirements that the BMS should meet, will be able to propose specific solutions.

Related products

Related posts

Now available – DC/DC converters from PREMIUM

Now available – DC/DC converters from PREMIUM

22-12-2020

We introduced a novelty to our permanent offer in DACPOL in the category of power supplies and converters and today...

Read more

New release in DACPOL lighting for lathes – Kira covers

New release in DACPOL lighting for lathes – Kira covers

14-11-2020

We introduce a new product into the DACPOL category of industrial lighting and today we offer KIRA covers for...

Read more

Leave a comment