Category

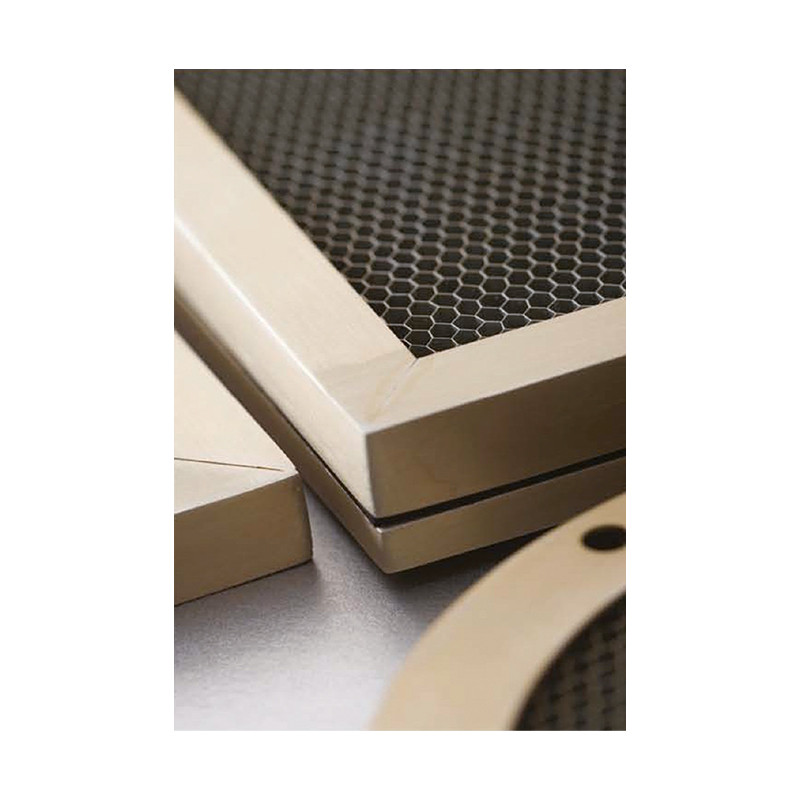

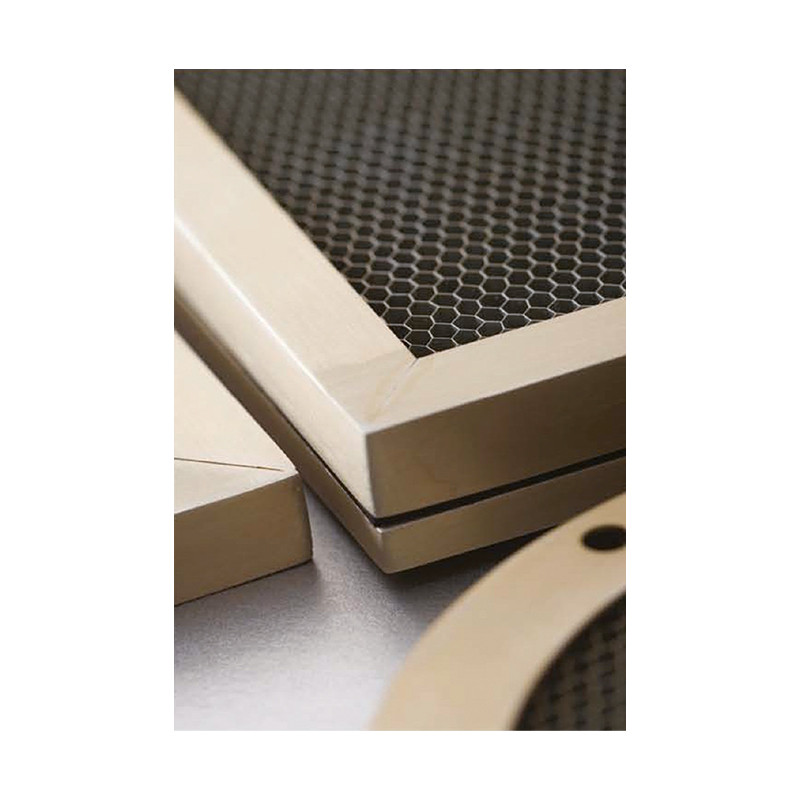

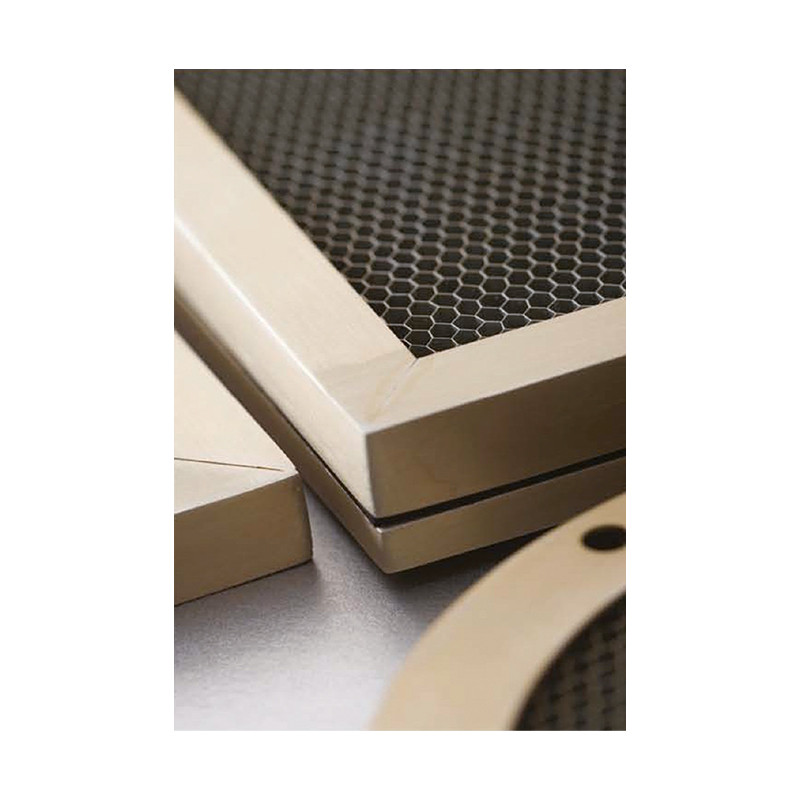

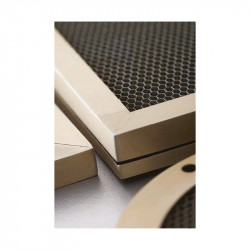

Photos are for informational purposes only. View product specification

please use latin characters

| FREQUENCY | WAVE | ALUMINUM |

|---|---|---|

| 10 KHz | H | 45 |

| 100 KHz | H | 49 |

| H | 51 | |

| 1MHz | E | >100 |

| 10MHz | E | >100 |

| 100MHz | E | >100 |

| 1GHz | P | 98 |

| 10 GHz | P | 95 |

Are you interested in this product? Do you need additional information or individual pricing?

| FREQUENCY | WAVE | ALUMINUM |

|---|---|---|

| 10 KHz | H | 45 |

| 100 KHz | H | 49 |

| H | 51 | |

| 1MHz | E | >100 |

| 10MHz | E | >100 |

| 100MHz | E | >100 |

| 1GHz | P | 98 |

| 10 GHz | P | 95 |

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent