Learn the basics of dredging and marine works – find out how dredgers, umbilical hose winch systems, and swivel joints support port operations and coastal protection.

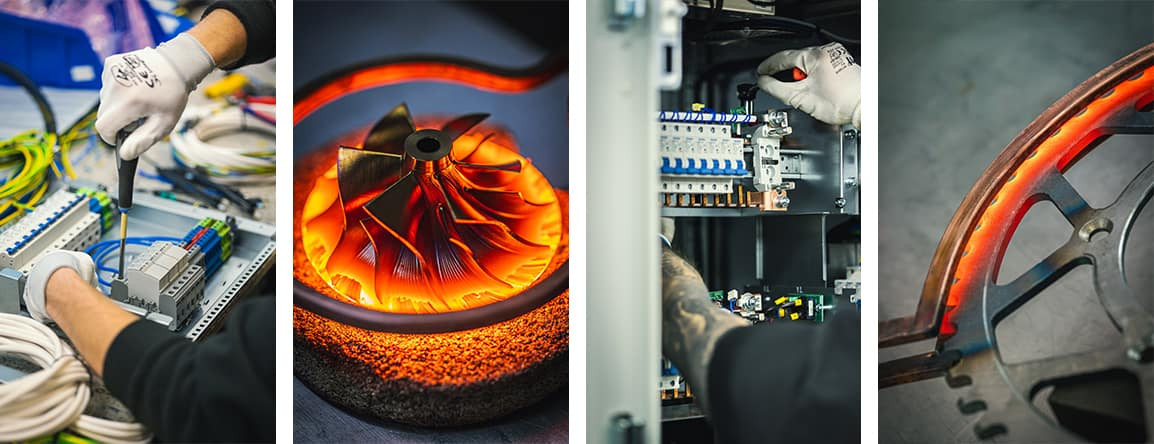

Components for power electronics, automations, electronics, electric

Suppliers

View all suppliersProduct Categories

View all categoriesLatest posts

-

How does a wind turbine workRead more

This article provides comprehensive information about wind turbines – their structure, operation, types, efficiency, advantages, and disadvantages. It also describes the installation and maintenance process, the importance of slip rings in ensuring reliable operation, and the prospects for wind energy development as a key source of clean, renewable power.

-

12 Commonly Asked Questions About Slip RingsRead more

This article discusses the 12 most frequently asked questions about slip rings and commutators. It explains their structure, function, and differences. The reader will learn why slip rings are used in motors, generators, and alternators, how they affect current flow, and their applications in various types of electrical machines. The article provides clear, practical explanations to help better understand how these components work.

![Components for Hazardous Areas & Explosive Atmospheres [Ex]](https://www.dacpol.eu/c/6823-catsmal_default/components-for-hazardous-areas-ex-59693.jpg)