-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- TEMPEST emission revealing filters

- Surge arrester

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Spiralift Lifts

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Cable feedthroughs and couplers

- Litz wires

- Cables for extreme applications

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Steel Braids

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

Fundamentals of Dredging and Marine Works

Dredging and marine works are processes that allow the maintenance of ports and waterways in good condition, protect coastlines, and provide materials for construction and land reclamation. Although it may sound complicated to many, the principles are simple – it involves removing sediments from the seabed and oceans and safely relocating them.

In this article, we will introduce you to the basics of dredging and marine works, present different types of dredgers, discuss umbilical hose reel systems, and explain the role of swivel joints and rotary unions. You will also learn about the main objectives of dredging – from maintaining navigability, through environmental protection, to port investments and the reclamation of contaminated areas.

If you are interested in marine works or planning dredging projects, this guide will be a practical source of knowledge for you.

Basics of dredging and marine works

Dredging and marine works are two common methods of removing sediments from the sea or ocean – both when they are submerged (dredging) and after the water has been drained or dried (land works).

These processes enable the maintenance of navigability in oceans and ports, support the protection of the marine environment, land reclamation, and beach restoration. Dredging and marine works can also be used to recover valuable materials such as minerals, sand, or gravel used in construction.

Dredging proceeds in four stages:

- Loosening of the material

- Raising it to the water surface

- Transport

- Storage or utilization

The material can be extracted by suction or mechanical methods and then transported in a water suspension through pipelines. The dredged material can be deposited in pits or used to replenish eroded coasts or build protective structures such as breakwaters or artificial islands.

Objectives of dredging and marine works

Maintenance

Dredging is used to deepen or maintain navigable waterways that gradually become silted. Maintaining the appropriate depth is crucial for navigation safety. Suction-reflux dredgers are used for this purpose. Most dredging works are performed to maintain water depth in waterways and port capacity.

Land reclamation

Dredging and marine works also allow for the extraction of sand and aggregates from the seabed. These materials are used in construction, shoreline protection, and prevention of flooding and erosion.

Investment dredging

This type of dredging aims to create or expand ports and navigation channels, increasing their capacity. Due to the presence of harder soil layers, cutter suction dredgers (Cutter Suction Dredgers – CSD) are used here.

Infrastructure preparation

Dredging can be performed as part of preparations for future investments – construction of quays, piers, or foundations for marine structures.

Reclamation of contaminated areas

This type of work aims to clean up contaminated areas, e.g., chemical spills, sewage sediments, or decomposing organic matter. The dredged material from such activities is usually disposed of safely.

Flood control

Dredging can increase the depth of a riverbed or port, enhancing its retention capacity and preventing floods.

Fisheries dredging

It is used for harvesting certain species of shellfish and edible mollusks.

Types of dredgers

Suction dredgers

Suction dredgers operate by sucking material through long pipes, similar to a vacuum cleaner. Most do not have sediment-disturbing tips. The main types include:

- Trailing Suction Dredgers (TSD) – the suction pipe is dragged along the seabed, and the dredged material goes to hoppers, which are emptied at the discharge site.

- Cutter Suction Dredgers (CSD) – equipped with a cutting device at the pipe inlet, loosening the sediment before suction and transport by centrifugal pumps.

- Auger Suction Dredgers (ASD) – use a rotating Archimedean screw, reducing water turbidity; often used in environmentally friendly projects.

- Jet-lift – use high-pressure water jets to stir and suction sediments.

- Air-lift – work by introducing air into the pipe; the air displaces water and lifts the sediment mixture upwards.

Mechanical dredgers

Mechanical dredgers are used to remove harder materials, e.g., coral reefs:

- Bucket Dredgers – equipped with rotating buckets to collect material from the seabed.

- Grab Dredgers – use a shell-shaped grab to extract sediments, e.g., port silt.

- Bed Levellers – dragged along the seabed by vessels to level it.

- Water Injection Dredgers – inject water at low pressure to move material in suspension.

- Pneumatic Dredgers – use chambers with water inflow; performance depends on depth and pressure.

Umbilical hose reel systems

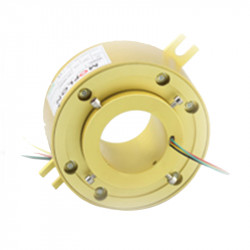

MOFLON produces rotary seals designed for umbilical hose reel systems. These solutions provide operational flexibility both on land and at sea.

Rotary unions are fully compatible with hose reel systems, allowing reliable and safe operation.

Applications:

- Pneumatic and hydraulic systems

- Transport of media, fuels, and working fluids

- Hose filling stations

Features:

- High-pressure constructions (up to 20,000 PSI and more)

- High flow rate

- Design according to customer requirements

- Corrosion resistance

- Customizable construction

Swivel joints

MOFLON swivel joints allow a full 360° rotation, providing flexibility in pipeline flow. This makes them ideal for modern dredging and marine processes.

Standard models operate at pressures up to 500 PSI and have inner diameters from 300 to 1100 mm. The double-seal technology allows servicing without disassembly, significantly reducing maintenance downtime.

Summary

MOFLON swivel joints perform excellently in demanding marine conditions – from installation and maintenance work to intensive operational use.

MOFLON has been developing its technologies for years, investing in research, innovation, and modern production facilities to deliver reliable solutions tailored to users' needs.

DACPOL is the official distributor of MOFLON Technologies products in Poland and provides full technical support and advice regarding their selection and application.

Related products

Related posts

Thermally conductive materials in power storages

Thermally conductive materials in power storages

Measuring power and energy in electric circuits

Measuring power and energy in electric circuits

Wentylatory przemysłowe - rodzaje, właściwości

Wentylatory przemysłowe - rodzaje, właściwości

Leave a comment