The article describes hydrogen fuel cells – a technology that converts hydrogen into electricity efficiently and environmentally friendly. It discusses the principles of fuel cell operation, their applications in automotive, industrial, and energy sectors, as well as advantages such as fast refueling, long range, and the possibility of integration with renewable energy sources. This technology represents a promising solution for sustainable development and energy transition.

Components for power electronics, automations, electronics, electric

Suppliers

View all suppliersProduct Categories

View all categoriesLatest posts

-

How Cabinet Cooling and Air Conditioning Affect the Lifespan of Electronic ComponentsRead more

The article discusses the importance of cooling and air conditioning in control cabinets for maintaining the lifespan of electronic components. It explains how stable temperature and humidity improve industrial system reliability, describes various cooling methods, the role of enclosure design and component layout, and highlights energy efficiency in modern industrial installations.

-

How do induction devices transform production processes?Read more

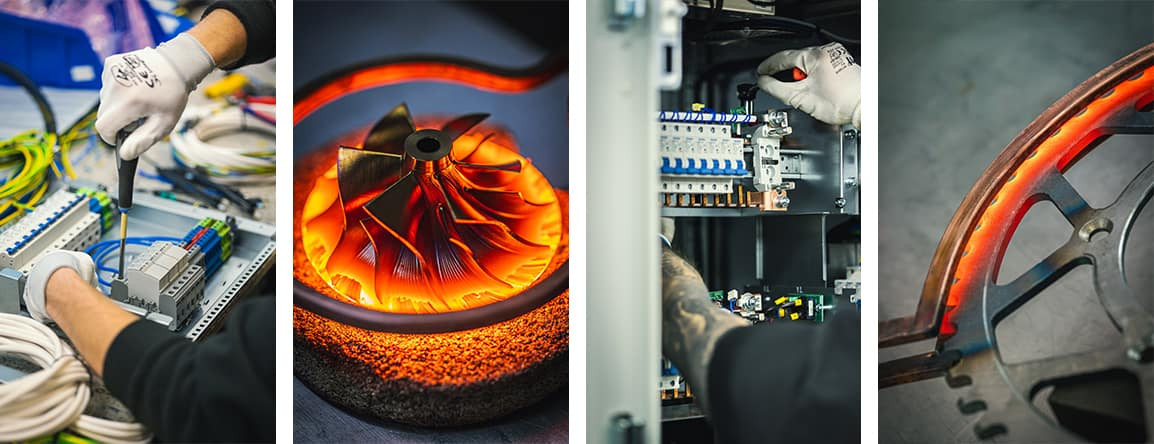

The article explains the principles of induction heating and shows why this technology is increasingly used in modern industry. It describes the design and operation of induction devices, their key advantages over traditional heating methods, and a wide range of applications—from hardening and brazing to metal melting and laboratory testing. The article also presents the capabilities of DACPOL SERVICE and highlights the company’s role as a technological partner in the design, implementation, and servicing of induction heating systems.

![Components for Hazardous Areas & Explosive Atmospheres [Ex]](https://www.dacpol.eu/c/6823-catsmal_default/components-for-hazardous-areas-ex-59693.jpg)