Category

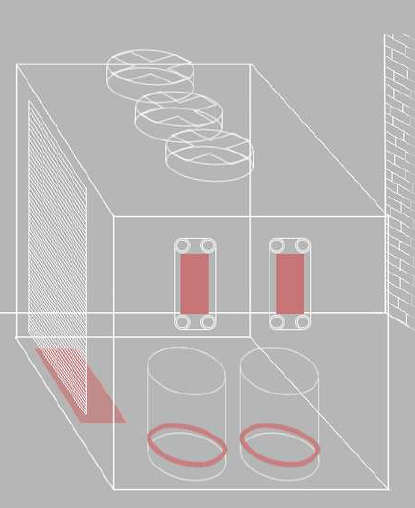

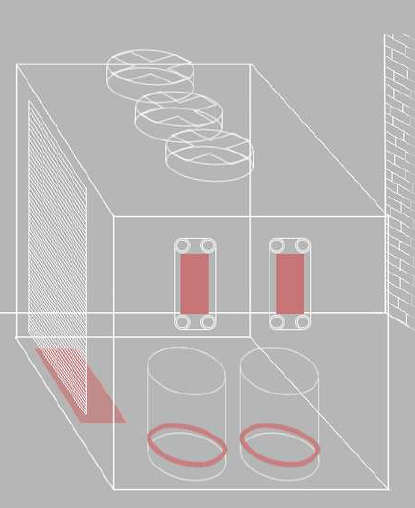

Photos are for informational purposes only. View product specification

please use latin characters

Alper heated clamping bands are characterized by a solid construction. The efficient knurled steel strap with a tensioning system allows for easy installation. It can be used in environments where a high IP class is required.

Heated clamping bands show excellent mechanical and electrical reliability both at high and low temperatures.

The use of heated clamping bands proves to be essential for maintaining the ideal functioning of the compressor. The Alper crankcase heater is a solution that adapts to all needs. It prevents bearing stress and facilitates engine start-up.

The use of a screw-in tension hook not only enables quick installation but also ensures excellent adhesion of the compressor crankcase heater, and thus ideal heat exchange with the compressor.

It is also possible to produce this crankcase heater according to customer specifications, with power cables of various lengths, resistant to UV rays and low temperatures.

The compressor crankcase heater can be equipped with protective thermostats and thermal fuses. Additionally, metal terminals or other connectors can be supplied at the customer's request.

OUR PRODUCTS CAN BE ADAPTED TO HVAC SYSTEMS USING PROPANE AS A REFRIGERANT.

Are you interested in this product? Do you need additional information or individual pricing?

Alper heated clamping bands are characterized by a solid construction. The efficient knurled steel strap with a tensioning system allows for easy installation. It can be used in environments where a high IP class is required.

Heated clamping bands show excellent mechanical and electrical reliability both at high and low temperatures.

The use of heated clamping bands proves to be essential for maintaining the ideal functioning of the compressor. The Alper crankcase heater is a solution that adapts to all needs. It prevents bearing stress and facilitates engine start-up.

The use of a screw-in tension hook not only enables quick installation but also ensures excellent adhesion of the compressor crankcase heater, and thus ideal heat exchange with the compressor.

It is also possible to produce this crankcase heater according to customer specifications, with power cables of various lengths, resistant to UV rays and low temperatures.

The compressor crankcase heater can be equipped with protective thermostats and thermal fuses. Additionally, metal terminals or other connectors can be supplied at the customer's request.

OUR PRODUCTS CAN BE ADAPTED TO HVAC SYSTEMS USING PROPANE AS A REFRIGERANT.

Crankcase heater – why it protects compressors

Crankcase heater – why it protects compressors

Printed Electronics

Printed Electronics

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent