-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- TEMPEST emission revealing filters

- Surge arrester

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Spiralift Lifts

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Cable feedthroughs and couplers

- Litz wires

-

Cables for extreme applications

- Extension and Compensation cables

- Thermocouple cables

- Connection cables for PT sensors

- Multi-conductor wires (temp. -60C to +1400C)

- Medium voltage cables

- Ignition wires

- Heating cables

- Single conductor cables (temp. -60C to +450C)

- Railway cables

- Heating cables Ex

- Cables for the defense industry

- Go to the subcategory

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Steel Braids

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

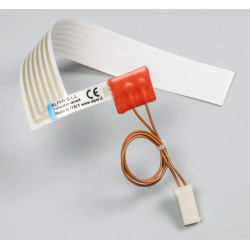

Crankcase heater – why it protects compressors

What a crankcase heater is, how it works, and features of a compressor heater

The crankcase heating belt — also known as a crankcase heater for compressors or a scroll compressor heater — is an electrical element that keeps the compressor above the refrigerant saturation temperature. This prevents refrigerant migration and oil dilution during off cycles. At start-up, non-diluted oil reduces friction, protecting bearings and moving parts, which improves reliability and lowers operating costs.

In heat pumps and chillers exposed to low ambient temperatures, a crankcase heater for compressors is often essential because it limits liquid slugging, hard starts, and mechanical stress typical of cold cycles. Therefore, it is a cornerstone of HVAC compressor protection, especially in systems operating in harsh climates or during extended stand-by periods.

How it works and why it is essential for heat pumps and chillers

The principle is simple: keep the compressor crankcase a few degrees above ambient temperature and above the refrigerant saturation temperature so condensation in the oil does not occur. In air-to-air and air-to-water systems, refrigerant migration during standstill is favored by cold spots; energizing the crankcase heater for compressors during off cycles — and in advance before restart — reduces condensation, prevents liquid carry-over damage, and improves start-up reliability.

Some models, such as a crankcase heater with a thermostat, automatically maintain the optimal oil temperature, increasing safety and start-up reliability.

Selection parameters

Choosing the right crankcase heater for compressors depends on:

- crankcase geometry (diameter/circumference),

- oil volume,

- refrigerant type, as saturation pressure sets the thermal threshold.

Heater power is sized according to heat losses (convection/radiation), contact surface, and compressor insulation; small crankcases typically start at a few tens of watts, with power increasing according to volume and exposure to cold. Contact quality is critical: a belt with a screw-type latch ensures uniform clamping, stable contact, and efficient heat transfer, simplifying installation and maintenance.

During installation, place the crankcase heater on the lower part of the crankcase (where refrigerant tends to accumulate), check insulation/IP rating, cable routing, and operating current. In cold climates, supply the heater sufficiently in advance to stabilize oil viscosity.

Crankcase heater features

A high-quality crankcase heater ensures uniform heat distribution. Its construction uses high-dielectric insulating materials and components designed to withstand repeated thermal cycles and vibration, preserving adhesion and the intended thermal profile.

The goal is proper heat transfer, achieving the power required to maintain ΔT, and preventing refrigerant migration into the oil during standstill, which can lead to dilution and loss of lubrication properties at start-up.

Continuous contact around the crankcase minimizes local temperature swings and mechanical stress, enabling smoother starts and reducing failures associated with liquid slugging. In HVAC systems with frequent on-off cycles, these features are crucial for effective compressor protection and better operational continuity.

Checks and maintenance

To ensure the crankcase heater works effectively:

- keep it energized during standstill,

- periodically check adhesion to the crankcase and cable integrity,

- monitor current draw.

For crankcase heaters with thermostats, check their response to temperature changes. Regular monitoring and early energizing before low-temperature start-ups prolong compressor life and reduce the risk of failures.

Two inspections per year are recommended — before and after the cold season. Long standstills require early energizing before restart.

Summary

A crankcase heater for compressors is a key element in protecting HVAC compressors in low temperatures. Thermostat-equipped versions additionally maintain optimal oil temperature automatically, improving start-up and minimizing wear. Using appropriate heaters increases system reliability and extends service life.

Related products

Related posts

Thermally conductive materials in power storages

Thermally conductive materials in power storages

Folia samoprzylepna z wypełnieniem ceramicznym

Folia samoprzylepna z wypełnieniem ceramicznym

Heat management - Challenges for electric vehicles

Heat management - Challenges for electric vehicles

Leave a comment