Industrial Power Connectors

Categories

Industrial Power Connectors: Reliability in Extreme Conditions

A key component of every production line

Industrial power connectors are advanced electrical installation components whose main task is to ensure a secure, durable, and safe electrical connection in automation systems, production machines, and devices requiring large current or high voltage supply. Unlike domestic connectors, they are designed and manufactured to withstand extreme environmental conditions such as high and low temperatures, moisture, dust, vibrations, and the presence of chemicals. Their reliability is crucial for the continuity and efficiency of the entire industrial plant's operation.

Construction and durability features

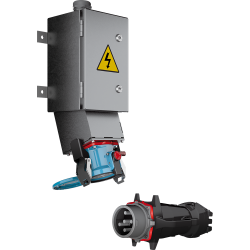

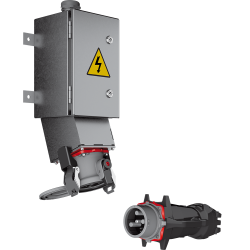

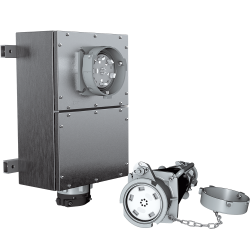

A complete industrial power connector is a modular system consisting of several elements selected for a specific application. Typical construction includes:

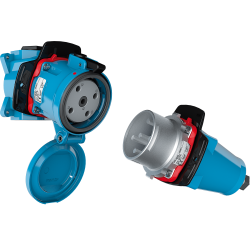

- Housing and cover: Usually made of durable metal or specialized plastic (e.g., halogen-free PP), providing a high degree of protection (often IP65, IP67, or IP68) against the ingress of dust and water.

- Inserts (male and female): Responsible for proper electrical contacts. They can transmit power, control signals, and in hybrid variants, even media such as compressed air.

- Pins/Contacts: Contact elements are often made of materials with high conductivity and corrosion resistance to ensure stable electrical parameters even under heavy load.

Thanks to their robust construction, these connectors guarantee the protection of the connection against accidental disconnection, mechanical damage, and negative environmental impact, which extends the lifespan of the entire installation.

Types and application in industry

Industrial power connectors are diverse, and their type is selected depending on the work specifics and required parameters. The offer includes:

- Multipole/Multicontact connectors: Designed for simultaneous transmission of multiple signals and power in one compact interface (e.g., rectangular HDC – Heavy Duty Connectors).

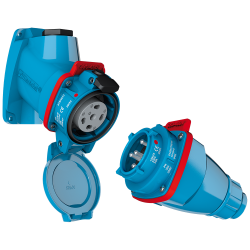

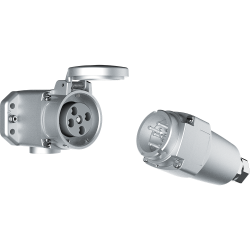

- High-current connectors: Dedicated to loads of hundreds of amperes (e.g., according to the IEC 60309 standard, commonly known as CEE or power connectors).

- Connectors with various connection techniques: Inserts may have screw, spring, PUSH IN clamps, or crimp pins, allowing optimal adaptation to assembly and vibration requirements.

- Hybrid connectors: Combine power paths (high power) with signal, fibre optic, or even pneumatic lines in a single housing.

The application of these connectors is versatile and includes, among others, machine building, robotics, energy (including renewable energy sources), rail transport, and all systems where fast, safe, and modular connection of power and control is required.