-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- TEMPEST emission revealing filters

- Surge arrester

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Spiralift Lifts

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Cable feedthroughs and couplers

- Litz wires

-

Cables for extreme applications

- Extension and Compensation cables

- Thermocouple cables

- Connection cables for PT sensors

- Multi-conductor wires (temp. -60C to +1400C)

- Medium voltage cables

- Ignition wires

- Heating cables

- Single conductor cables (temp. -60C to +450C)

- Railway cables

- Heating cables Ex

- Cables for the defense industry

- Go to the subcategory

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Steel Braids

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

Ferrite Cores – How They Affect the Efficiency of Inductive Circuits

Every inductive component, such as a coil or transformer, requires a suitable material that can conduct the magnetic flux. The core forms the basis of such components, and its magnetic properties have a key impact on the performance of the entire system. In modern electronics, ferrite cores are increasingly used, combining high magnetic permeability with low loss. This allows devices to operate stably, even at high frequencies.

Inductive nature of components and their role in electronics

Inductive components, i.e., coils and transformers, play an indispensable role in power supply circuits, filters, and signal transmission systems. They are responsible for storing energy in the magnetic field, separating circuits, and eliminating interference. The performance of such a component directly depends on the parameters offered by the ferrite core – from its inductance, core losses, to the DCR factor.

Ferrite core – what it is and why it is important

A ferrite core is made from metal oxides, most commonly iron combined with manganese, zinc, or nickel. Ferrites have high magnetic permeability and low losses over a wide frequency range. This makes ferrite cores ideal for high-frequency applications where metallic components would cause excessive losses due to eddy currents.

Coil and transformer – examples of ferrite core applications

In inductive coils, a ferrite core increases the inductance and allows stable parameters under various operating conditions. In pulse transformers used in power supplies, the core enables efficient operation at high frequencies, minimizing core losses and improving the overall system energy efficiency.

Ferrites in industrial and electronic applications

Ferrites are widely used in consumer electronics, industrial applications, and telecommunications. Ferrite cores are utilized in EMI filters, antennas, resonant coils, and signal transformers. In each of these applications, key considerations include suppressing electromagnetic interference, minimizing losses, and ensuring optimal current flow.

Core material and system efficiency

The core material determines the properties of a coil or transformer. High magnetic permeability means higher inductance with fewer turns, and low core losses provide better efficiency and less heating. Ferrite cores also help reduce electromagnetic interference, which is critical in electronic systems requiring stable operation.

Ferrite core in switching electronics

Switching power supplies are one of the most common examples of ferrite core applications. They enable efficient energy conversion across a wide frequency range, and the entire system operates with high efficiency. The ferrite core dissipates excess energy, reduces core losses, and stabilizes the magnetic flux, allowing component miniaturization while maintaining performance.

How ferrite cores work

Ferrite cores use the properties of magnetic materials with high permeability that efficiently conduct magnetic flux. Unlike metallic cores, they minimize eddy currents, reducing energy losses. This allows components such as inductive coils to operate more efficiently, and transformers to provide higher efficiency in high-frequency circuits.

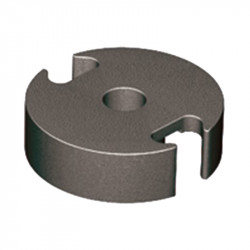

Ferrite core constructions

Ferrite cores are available in various constructions – toroidal, cylindrical, or E and U shapes. The choice of shape depends on the intended application. Toroidal cores provide low electromagnetic interference, while E-cores simplify mounting and winding in power supply systems.

Efficiency and core losses

One of the key parameters to consider is core loss. These losses result from the material properties and operating frequency. Ferrite cores limit these losses, ensuring high efficiency of the inductive component. The DCR parameter, or direct current resistance, affects the heating of windings and the entire coil.

Ferrite core in high-frequency applications

Modern electronic systems increasingly require operation at high frequencies. Ferrite cores, due to their properties, are particularly well-suited here. They are effective in EMI filters, communication antennas, and transformers operating at high DC voltage.

Ferrites dedicated to electronics

Ferrites are designed to meet specific requirements of different applications. In telecommunications electronics, suppressing electromagnetic interference is especially important; in power systems, energy efficiency; and in filters, the effectiveness of unwanted signal reduction. The core material is therefore selected based on the requirements of the application.

DCR and other parameters important for design

When designing inductive components, engineers must consider many parameters. DCR defines losses in the windings, while the magnetic properties of the core determine the overall component efficiency. Ferrite cores provide a balance between high inductance and low losses.

Practical applications – from filters to power supplies

Ferrite cores can be found in almost every modern electronic device. From EMI filters in computers and mobile devices, through coils in converters, to pulse transformers in power supplies. They enable stable electronic operation, preventing interference and overheating of devices.

Summary – core materials and the future of electronics

The ferrite core is a key element in modern inductive circuits. Thanks to ferrite properties, it is possible to design more efficient, energy-saving, and interference-resistant devices. Their role in electronics is invaluable – from inductive coils, through transformers, to advanced telecommunication systems.

Related products

Related posts

Thermally conductive materials in power storages

Thermally conductive materials in power storages

Measuring power and energy in electric circuits

Measuring power and energy in electric circuits

Wentylatory przemysłowe - rodzaje, właściwości

Wentylatory przemysłowe - rodzaje, właściwości

Leave a comment