-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- TEMPEST emission revealing filters

- Surge arrester

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Spiralift Lifts

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Cable feedthroughs and couplers

- Litz wires

-

Cables for extreme applications

- Extension and Compensation cables

- Thermocouple cables

- Connection cables for PT sensors

- Multi-conductor wires (temp. -60C to +1400C)

- Medium voltage cables

- Ignition wires

- Heating cables

- Single conductor cables (temp. -60C to +450C)

- Railway cables

- Heating cables Ex

- Cables for the defense industry

- Go to the subcategory

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Steel Braids

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

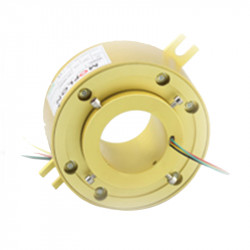

Guide to Rotary Connectors

DACPOL offers a wide range of rotary joints that are used in the defense, aerospace, industrial, and commercial sectors. To achieve optimal performance from a rotary joint, proper selection, correct installation, and regular maintenance are essential. This guide aims to cover the basics, key terminology, misalignment issues, and a comparison of main design types.

Rotary Joint Basics

What is a rotary joint?

A rotary joint is a mechanical device that acts as an interface allowing the transfer of a fluid medium – air, steam, or liquid – between a rotating component and a stationary component.

Main components of a rotary joint:

- Body / Housing: The stationary part that contains the medium and may facilitate hose connections. It also acts as a torque limiter.

- Rotor / Nipple: The rotating part that connects the joint to the moving machine element. Threaded (tapered, straight) and flange connections are available.

- Guide / Guide Bushings: The section that transmits rotational force, ensuring proper alignment of the rotary joint.

- Seal: This is the first part of the swivel to wear out. The lifespan of the seal is determined by operating parameters such as machine speed, temperature, and type of medium.

- Mounting Plate: A component placed between the joint head and the housing, designed to protect internal components during head removal.

Technical Terminology

Enhance your knowledge of rotary joints by learning the following key terms:

- Anti-Rotation Rods: Rigid, smooth rods that connect the joint body to a stationary external surface, preventing the joint from rotating.

- Balanced Seal: A sealing technique commonly used for water and coolant (but also possible for steam and gases), which relies on an external spring pressure to ensure positive sealing inside the joint.

- Dryer Bars: Axial stainless steel rods installed inside cylinders to induce turbulence, increasing surface temperature uniformity and heat transfer efficiency.

- Dual Flow: Medium flows to and from the rotary joint via a siphon or internal distribution tube.

- Externally Supported Rotary Joints: Designs that rely on an external stationary machine frame to support the joint body.

- Flexible Metal Hose: A hose that maintains medium pressure and provides the flexibility needed for proper joint movement.

- Guide: A type of carbon bushing mounted around the nipple, used to support the rotary joint.

- Medium: Fluids (liquids, gases, steam) transmitted through rotary joints.

- Multi-Passage Unions: Joints necessary when more than one medium is used simultaneously, requiring multiple seals between stationary and rotating connections.

- Pressure Joint: A type of joint where the internal sealing ring carries the full force generated by the internal fluid pressure.

- Rotor: The rotating part of the rotary joint that connects to the rotating equipment (may be threaded or flanged).

- Seal Rings: The primary consumable element. During operation, the rings experience forces from fluid pressure and friction.

- Sight Flow Indicators: Devices that provide visual observation of liquid and gas flow in a pipeline.

- Single-Flow: Medium flows in only one direction through the rotary joint, also known as unidirectional flow.

- Syphon: A pipe system inside a rotating cylinder that allows fluid to exit through the joint.

- Wear Plate: A replaceable metal sealing plate attached to the joint body, designed to be replaced after reaching the end of its service life.

Rotary Joint Misalignment

The main cause of premature failure of the carbon seal ring is rotary joint misalignment. Misalignment occurs when the swivel vibrates during operation. As a result, the carbon seal ring is stressed relative to the inner diameter of the housing, which can lead to uneven wear.

Preventing misalignment:

The rotary joint should be installed with flexible metal hoses. As the seal ring wears, an uncompensated joint will slightly move away from the trunnion end – flexible hoses must allow for this. Hoses must have adequate length to provide this flexibility. All connected bolts should be tightened properly on each section, and tightening should be performed gradually, in a cross pattern (e.g., 180 degrees apart).

Achieving Optimal Performance

After proper installation, the main wear component remains the seal ring. It should be replaced once it reaches maximum wear. Failure to replace it can result in metal surfaces coming into contact, causing irreversible damage to the rotary joint.

Critical factors for wear:

Machine speed, pressure, and temperature are critical for the wear characteristics of mechanical seals. The actual compressive load on the seal ring is directly related to operating pressure. As pressure increases, the seal load increases. Increased load combined with machine speed increases frictional power loss and generates higher temperatures. Overall, seal wear rate increases with both operating speed and pressure.

Selecting the correct sealing material is a key factor, taking into account all costs associated with seal failure.

Carbon Guides vs. Rolling Bearings

The choice between a rotary joint supported by carbon guides and one with rolling bearings depends on several factors:

Rotary joints supported by carbon guides are best suited for low speeds and high temperatures. Carbon has a low coefficient of thermal expansion, allowing it to tolerate significant temperature differences. The joint nipple heats up quickly and expands, while the body heats more slowly. In such joints, only additional clearance on the inner diameter (ID) of the guide is needed to handle thermal expansion. In contrast, in joints with rolling bearings, thermal expansion must be accommodated by the bearing internal clearance, making bearing selection temperature-dependent. Carbon guides do not require lubrication or servicing, except for replacing worn seals. They also have advantages for larger sizes, as they are easier to order than large rolling bearings.

Joints supported by rolling bearings are typically used in high-speed applications and where axial runout is critical. High-speed joints often use balanced face seals, which require precise alignment of sealing surfaces. Rolling bearings are also preferred in applications requiring low drive torque. Some rolling bearing applications require adherence to a lubrication maintenance schedule for optimal life.

Summary

We have covered important aspects of rotary joints: from basic components, through detailed terminology, to factors affecting their performance such as misalignment, speed, pressure, and choice of support design (carbon guides vs. rolling bearings).

Proper selection, installation using flexible hoses, and timely replacement of worn seal rings are the foundations of long-lasting and trouble-free operation of any joint. Remember, optimal performance and longevity depend on precisely matching the joint parameters to the conditions in your machine.

If you need technical support in selecting rotary joints, taking into account the specifics of your application, contact DACPOL specialists. We will gladly help you find the ideal solution.

Related products

Related posts

Thermally conductive materials in power storages

Thermally conductive materials in power storages

Measuring power and energy in electric circuits

Measuring power and energy in electric circuits

Wentylatory przemysłowe - rodzaje, właściwości

Wentylatory przemysłowe - rodzaje, właściwości

Leave a comment