-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- TEMPEST emission revealing filters

- Surge arrester

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Spiralift Lifts

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Cable feedthroughs and couplers

- Litz wires

- Cables for extreme applications

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- Galvanized and Stainless Steel Cylindrical Braids

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

How to Choose a Heatsink for Power Electronics Systems

In power electronics systems, heat dissipation from components is one of the key aspects ensuring reliable operation of devices. A heatsink serves as the main passive cooling element, allowing the heat generated by electronic components, processors, or power transistors to be dissipated. Proper selection of a suitable heatsink can significantly improve system efficiency, extend the lifespan of components, and reduce the risk of failure.

In practice, designing a heatsink requires a combination of knowledge in electronics, thermal conductivity of materials, and an understanding of convection and radiation processes within the system.

Basics of Heatsink Design

When designing a heatsink for electronic systems, several key parameters must be considered:

- The amount of heat generated by components,

- The maximum allowable operating temperature,

- The thermal conductivity of the heatsink material,

- The surface area and fin geometry,

- The presence or absence of forced airflow via fans.

The basics of heatsink design include understanding the transfer of heat from the component to the heatsink and then to the environment. In power electronics systems, heat dissipation can occur through both natural and forced convection using a fan.

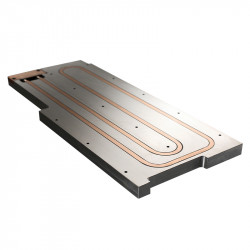

Heatsink Materials

When selecting heatsink material, thermal conductivity is crucial. The most commonly used materials are:

- Aluminum – lightweight, relatively good thermal conductivity, easy to machine, commonly used in passive heatsinks,

- Copper – excellent thermal conductivity, higher thermal performance, but heavier and more expensive.

Heatsink performance depends on the material properties, surface area, and fin arrangement. The larger the heatsink surface, the better it dissipates heat and improves system thermal efficiency.

Heatsink Construction – Shape and Surface

The construction of the heatsink is critical for effective cooling of electronic devices. Common design elements include:

- Fins that increase the heat exchange surface area,

- Flat bases that ensure good contact with the component,

- Ventilation holes allowing airflow in case of forced cooling.

When designing a heatsink, it is important to calculate thermal resistance between the component and the heatsink, as well as between the heatsink and the environment. Proper heat dissipation depends not only on the surface area but also on the heatsink shape, which should promote natural or forced airflow.

Heatsink Calculations and Selection

To choose an appropriate heatsink, engineers must perform thermal calculations considering:

- The amount of heat generated by components (in watts),

- The allowable operating temperature of the electronic component,

- Parameters of the heatsink material's thermal conductivity,

- The efficiency of heat dissipation via convection and radiation.

In practice, formulas for heatsink thermal resistance are used, defining the temperature difference between the component and the environment relative to the heat power. Heatsink calculations allow predicting whether a component can effectively dissipate heat in a power electronics system and ensure system performance.

Passive vs Active Cooling

Passive heatsinks rely only on conduction and radiation to dissipate heat, making them quiet and reliable, but their performance depends on surface area and material conductivity.

For high-power systems, active cooling is often used, which enhances the heatsink with a fan. Forced airflow increases the rate of heat transfer and allows better dissipation from electronic components.

Best Practices in Heatsink Design

When designing a heatsink, it is recommended to follow several proven principles:

- Select heatsink material with good thermal conductivity – aluminum or copper,

- Increase heatsink surface area by using fins and appropriate shapes,

- Consider forced airflow when the heat load is high,

- Use high-quality thermal interface materials between the component and the heatsink,

- Calculate thermal parameters before selecting the heatsink to avoid overheating.

A properly designed heatsink significantly affects system efficiency, cooling effectiveness of electronic devices, and reliability of electronic components, especially in high-power applications.

Applications of Heatsinks in Electronics and Power Electronics

Heatsinks are used in high-power electronics systems, including:

- Power supplies, converters, and inverters,

- Motor controllers and industrial systems,

- Processors and other electronic components,

- Electronic devices with high heat generation.

Selecting heatsink dimensions and material allows effective heat dissipation and increases thermal efficiency and component lifespan.

Summary

The heatsink is a key element of cooling power electronics systems. Proper selection requires knowledge of heatsink design basics, component parameters, and materials with high thermal conductivity. A well-designed cooling system ensures effective heat dissipation, stable operating temperatures, and long lifespan of electronic components.

We invite you to explore our offer – we provide a wide range of heatsinks and cooling systems for power electronics. See how our solutions can enhance the efficiency and reliability of your devices.

Related products

Related posts

Thermally conductive materials in power storages

Thermally conductive materials in power storages

Measuring power and energy in electric circuits

Measuring power and energy in electric circuits

Wentylatory przemysłowe - rodzaje, właściwości

Wentylatory przemysłowe - rodzaje, właściwości

Leave a comment