-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

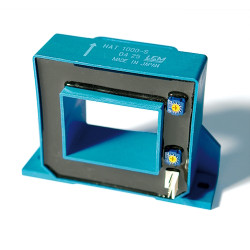

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- TEMPEST emission revealing filters

- Surge arrester

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

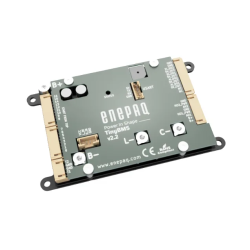

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Spiralift Lifts

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Cable feedthroughs and couplers

- Litz wires

-

Cables for extreme applications

- Extension and Compensation cables

- Thermocouple cables

- Connection cables for PT sensors

- Multi-conductor wires (temp. -60C to +1400C)

- Medium voltage cables

- Ignition wires

- Heating cables

- Single conductor cables (temp. -60C to +450C)

- Railway cables

- Heating cables Ex

- Cables for the defense industry

- Go to the subcategory

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Steel Braids

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

Industrial Automation – What It Is and Its Applications

Industrial automation is a field of engineering that plays a key role in modern industry. In short, industrial automation deals with automation of production processes, which allows for increased efficiency, improved product quality, and optimization of entire production lines. Its main goal is to enable the control of devices and systems in an automatic way, minimizing human involvement in repetitive or precise tasks.

In practice, industrial automation involves the integration of various automation components such as PLC controllers, sensors, SCADA systems, industrial robots, or software for managing industrial processes. This makes it possible to effectively monitor and control processes in real time.

What is industrial automation?

Industrial automation is an engineering field that combines electrical, electronic, and computer engineering to enable automation of industrial production. Industrial automation systems consist of several key elements:

- Sensors – collect data from the environment and processes, e.g., temperature, pressure, flow;

- PLC Controllers (Programmable Logic Controllers) – process data and generate control signals for actuators;

- Actuators – such as motors, actuators, pumps, which execute commands from the controller;

- SCADA and HMI software – allows operators to monitor, manage, and optimize production processes in real time;

- Industrial robots and vision systems – used in advanced process automation and quality control.

Industrial automation allows for the control of entire production processes, increasing machine precision, reducing downtime, and lowering operational costs.

Industrial automation systems

Industrial automation systems can cover various branches of industry: from food industry, through chemical, to machinery and electronics manufacturing. They consist of devices and systems that process data from sensors, analyze it, and control actuators automatically.

In practice, one can distinguish:

- Production automation – production lines, packaging, assembly, sorting;

- Industrial process automation – controlling fluid flow, pressure, temperature in chemical and energy plants;

- Quality control automation – vision systems, sensors, industrial robots;

- Production management – SCADA systems allow monitoring and analyzing line operations in real time, enabling rapid response to irregularities.

Applications of industrial automation

Industrial automation has wide applications across various industries. It includes process control systems that enable:

- Improvement of product quality through precise control of process parameters;

- Optimization of production by minimizing downtime and raw material waste;

- Increased workplace safety – automatic systems detect failures and respond appropriately;

- Reduction of operational costs – automation reduces the need for manual operation, thus lowering the risk of errors and failures;

- More efficient data management – collecting and processing data in real time allows for immediate operational decisions.

Examples of applications include assembly lines, food industry, chemical industry, energy industry, and production of electronic devices. In each of these sectors, industrial automation increases process repeatability, shortens production time, and reduces the risk of equipment damage.

Key components of industrial automation

In industrial automation, the key components are:

- PLC controllers – central control units that process sensor data and control actuators;

- Sensors – allow monitoring of process parameters, e.g., temperature, pressure, flow;

- Actuators – actuators, pumps, motors that execute commands from the controller;

- SCADA and HMI systems – allow operators to manage processes, analyze data, and optimize production;

- Industrial robots – increase repeatability and precision of actions on production lines;

- Software – enables integration of all components and execution of advanced control algorithms.

Industrial production automation

Industrial production automation is an integral part of modern industry. It allows for:

- Real-time process control,

- Integration of different devices and systems,

- Optimization of production parameters,

- Increased efficiency and product quality,

- Reduction of operational and energy costs.

Industrial automation enables the creation of intelligent production lines that minimize human involvement in repetitive tasks while allowing operators to supervise the process.

The future of industrial automation

The future of industrial automation is linked to the development of new technologies such as artificial intelligence, machine learning, vision systems, and collaborative robots. Modern industrial automation systems allow for:

- Predictive process monitoring,

- Advanced analysis of sensor data,

- Real-time optimization of production processes,

- Increased workplace safety,

- More efficient use of resources and energy.

Industrial automation continues to evolve, integrating modern technologies with traditional control systems, leading to the creation of more efficient, intelligent, and flexible production lines.

Summary

Industrial automation is an engineering field focused on automating production processes and controlling industrial systems. It enables production optimization, increased efficiency, improved quality, and enhanced workplace safety. Industrial automation implementations include PLC controllers, sensors, SCADA systems, industrial robots, and other automation components that together form advanced process control systems.

Industrial automation is used in many industries – from food production, through chemical industry, to electronics and machinery manufacturing. It allows for automation of industrial production, cost reduction, minimization of downtime, and increased process precision.

We invite you to explore our offer and discover how industrial automation solutions can increase the efficiency and safety of your production. Check out our systems and components that will help optimize every industrial process.

Related products

Related posts

Thermally conductive materials in power storages

Thermally conductive materials in power storages

Measuring power and energy in electric circuits

Measuring power and energy in electric circuits

Wentylatory przemysłowe - rodzaje, właściwości

Wentylatory przemysłowe - rodzaje, właściwości

Leave a comment