Installing POWERSAFE (POWERLOCK) connectors involves several proven methods, such as bolting, threaded stud mounting, crimping, clamping, and soldering. Each requires proper cable preparation, suitable accessories, and the use of the correct tools. It is crucial to follow the manufacturer’s recommendations and ensure that all work is performed by qualified electricians. After assembly, regularly check the condition of insulators, seals, and connections to ensure safe and long-lasting system...

Knowledge Base

-

How to Safely Connect POWERSAFE (POWERLOCK) ConnectorsRead more

Learn how to safely connect POWERSAFE (POWERLOCK) connectors with our step-by-step guide. We provide detailed instructions for connecting and disconnecting connectors, as well as highlight POWERSAFE distribution box features such as up to 800A current handling and remote control. Ensure the safety and efficiency of your connections!

-

(Preventive) Explosion Protection MeasuresRead more

The article describes the principles of secondary explosion protection — actions taken when it is not possible to completely avoid the formation of explosive atmospheres or ignition sources. The purpose of these measures is to limit the effects of an explosion to a level that is safe for people, installations, and the environment.

-

Sources of Ignition Covered by the ATEX DirectiveRead more

The article discusses one of the key issues in explosion protection – sources of ignition, which constitute one of the three main elements of explosion risk (alongside combustible substances and oxidizers). It highlights that without sufficient ignition energy, an explosion cannot occur; therefore, eliminating or minimizing ignition sources is a fundamental preventive measure.

-

Flammability of grain – what factors influence flammability?Read more

The article discusses process safety principles in the food industry, with particular emphasis on the hazards of grain dust explosions. It presents explosiveness parameters, factors influencing the risk of explosion, and elements of installations most exposed to failures. It also describes the stages of analysis and classification of explosion hazard zones in accordance with ATEX requirements.

-

How POWERLOCK Connectors Work: Key Aspects and Operating PrinciplesRead more

Learn how POWERLOCK connectors provide reliability and performance in power systems. Read about their design, operating principles, impact on energy efficiency, and safety standards. Discover different types of POWERLOCK connectors and their applications across various industries, as well as the future of this technology.

-

MTL solutions in ATEX zonesRead more

The article discusses the occurrence of explosive atmospheres in industrial plants and the classification of hazardous zones according to ATEX directives and applicable standards. It explains the differences between zones 0, 1, 2 and 20, 21, 22, emphasizing the importance of using intrinsically safe equipment to minimize ignition risks. The second part presents Eaton MTL’s solutions — both wired and wireless Ethernet systems designed for Ex zones — ensuring reliable and safe industrial...

-

Industrial RFIDRead more

Radio-Frequency Identification (RFID) is a short-range, automatic, and contactless communication method that uses electromagnetic fields to receive and read information about an object stored on a tag.

-

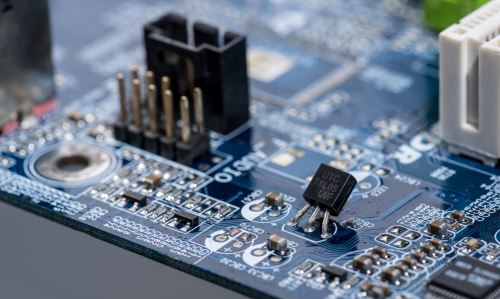

Why does my PCB design fail EMC tests?Read more

The article is a comprehensive guide to designing electronic devices with electromagnetic compatibility (EMC) in mind. It explains what EMC tests are and why passing them is crucial, then describes the most common causes of failure—from radiated emissions and poor shielding to errors in ESD protection. The author discusses good PCB design practices: controlling return paths, proper layer stack-up, using stitching vias, enclosure shielding, correct cable shielding and termination, as well as...

-

What are shielded cabinets and enclosures?Read more

The article explains what shielded cabinets and enclosures are and how they protect electronic equipment from electromagnetic interference (EMI) and electromagnetic pulses (EMP). It describes their operation as a Faraday cage, practical applications in data centers, laboratories, the military sector, and industry, as well as how to select the attenuation level according to needs. It emphasizes that investing in such solutions increases equipment reliability and data security.

-

How Does the Magnetic Field Penetrate Shielding Materials? Analysis and ComparisonRead more

The article discusses the penetration of magnetic fields through shielding materials and the factors determining the effectiveness of protection: the skin effect, the presence of holes and gaps, and the conductivity of fibers across different frequency ranges. It presents the results of tests on six materials – from ineffective to highly attenuating – emphasizing that the choice of shielding requires consideration of electrical properties, structure, and operating frequency.

-

Rogowski Coils – Construction and Principle of OperationRead more

Rogowski coils are built with a flexible core made of insulating material, around which very precise and tightly wound turns of thin, insulated wire are wrapped. The ends of the winding are connected to an electronic circuit that processes the signal.

-

How to Choose Thread Locking Products?Read more

The article discusses how to choose the appropriate thread locking products, including anaerobic adhesives, spring washers, and tapes. The tips cover factors that influence the choice, as well as practical application advice.

-

What Are Anaerobic Adhesives?Read more

Learn about anaerobic adhesives, how they work, and the benefits they offer in challenging environments. Explore their applications in high-temperature, vibration, and pressure conditions, and discover how they contribute to the durability of threaded connections. Understand their diverse uses across industries like automotive, food production, and pharmaceuticals.

-

Vector Analysis of Circuits: The Key to Precise Electronics Design and DiagnosticsRead more

Vector analysis of circuits is an advanced method used in electronics to evaluate electrical circuits, particularly in the context of alternating current (AC) signals. By representing signals and impedances as vectors in the complex plane, it allows for precise visualization and analysis of their behavior as a function of frequency.

-

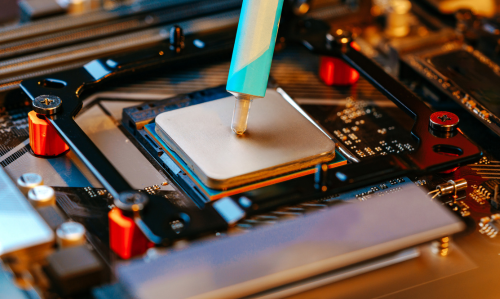

Application of Liquid Thermal Conductive Materials in the Electronics Industry: Effective Cooling for Performance and ReliabilityRead more

In today's world, where more and more electronic devices generate significant amounts of heat, efficient cooling becomes a key factor in ensuring the reliability and performance of these systems. In response to this challenge, the electronics industry is increasingly turning to innovative solutions such as liquid thermal conductive materials.

-

Comparison of capacitive and resistive touch panels: Which solution is better for your business?Read more

Choosing the right touch solution can be a challenge for many companies looking to implement innovative technologies in their products or processes. The two most commonly used types – capacitive touch screens and resistive touch panels – have unique advantages and are used in various environments. Understanding these differences will help select the ideal solution to ensure optimal performance, durability, and user convenience in a given application.

-

Environmental resistance of capacitive touch panels: Key features for industrial applicationsRead more

In industry, the reliability and durability of devices are crucial, especially in challenging environmental conditions. In many sectors, such as manufacturing, logistics, energy, or heavy industry, technologies must withstand various challenges – from extreme temperatures and high humidity to dust and chemical exposure. In this context, capacitive touch screens stand out due to advanced technology and appropriate design, enabling their use in demanding environments.