-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- TEMPEST emission revealing filters

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Spiralift Lifts

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Cable feedthroughs and couplers

- Litz wires

- Cables for extreme applications

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- Galvanized and Stainless Steel Cylindrical Braids

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

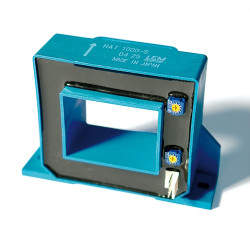

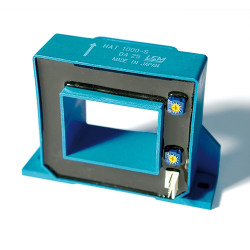

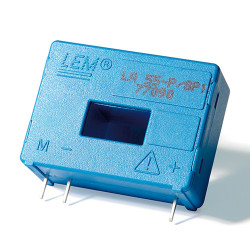

Which Current Transducer to Choose?

A current transducer is a measuring device designed to measure the electric current flowing in a circuit and convert it into a standard output signal, easy to interpret by a controller or another control system. This can be a voltage signal (0–10 V) or a current signal (e.g., 4–20 mA). Thanks to this, the measuring transducer makes it possible to monitor changes in current intensity in devices, machines, and electrical installations.

The transducer is essential in systems where it is necessary to safely and accurately measure the primary current and then convert it into a secondary signal with lower values, adapted to measuring devices.

Current and measurement – why are transducers used?

Electric current in a circuit can reach very high values. Measuring it directly with conventional meters would be dangerous and impractical. For this reason, current transducers are used, which convert the primary current into a proportional output signal.

A current measuring transducer allows for:

- monitoring energy consumption,

- controlling the operation of industrial equipment,

- protecting electrical systems against overloads,

- integration with automation systems and PLC controllers.

Current transducer – principle of operation of a current transformer

The basic component of many current transducers is the current transformer. It consists of a magnetic core as well as a primary and a secondary winding.

- The primary current flows through the primary winding, creating a magnetic field in the core.

- The magnetic field induces a current in the secondary winding, which is proportional to the primary current.

- Thanks to this, it is possible to measure very high currents, obtaining a secondary signal in a safe range for measuring devices, e.g., 5 A.

This principle of transformer operation makes the current transducer suitable for measuring alternating (AC) and direct (DC) currents, depending on the device’s construction.

Types of current transducers

In practice, different types of transducers are used depending on the nature of the current and the application.

- AC current transducer – used to measure alternating current in power supply networks.

- DC current transducer – designed to monitor direct current in technological systems.

- Measuring transducer with analog output – generates a signal of 0–10 V, 0–20 mA or 4–20 mA.

- Current transducer with Modbus RTU – modern digital devices that transmit data to controllers via the RS485 communication interface.

Some models are dual transducers, allowing simultaneous measurement of two circuits.

Current transformer – classic measuring element

The current transformer is a type of transducer that has been used in power engineering for decades. It uses the phenomenon of magnetic induction and, thanks to a properly selected winding ratio, enables safe measurement of high-value primary current.

For example, the primary current in a circuit may be 200 A, and the current transformer converts it into a 5 A secondary current, which can be safely connected to an ammeter, PLC controller, or current measuring transducer.

Current measuring transducer in industrial automation

In industrial automation, current transducers play a key role in monitoring and protecting installations. The controller receives a standardized electrical signal and, based on it, can switch the circuit off, control the process, or monitor energy consumption.

This makes it possible to:

- track current values in real time,

- detect overloads,

- optimize equipment operation,

- reduce energy losses.

AC and DC current transducer

Depending on the type of current, we distinguish:

- AC transducers – designed to convert the measured alternating current, e.g., in network installations,

- DC transducers – used in devices powered by direct current, such as batteries or photovoltaic systems.

In practice, hybrid solutions can also be found, enabling current measurement in both modes.

Transducer outputs – analog and digital

The current transducer can generate various output signals:

- Analog – 0…10 V, 0…20 mA or 4…20 mA. These signals are easy to connect and widely used in automation systems.

- Digital – e.g., Modbus RTU, which allow precise transmission of measurement data and integration with larger systems.

Thanks to this, the current measuring transducer can be used both in simple applications and in advanced energy management systems.

Accuracy and measuring range

When choosing a current transducer, attention should be paid to:

- primary current range (e.g., 0…20 A, 0…100 A, 0…500 A),

- measurement accuracy,

- type of output signal,

- galvanic isolation,

- compatibility with the selected controller or meter.

In many industrial applications, transducers with a 5 A output are used, which is the standard in secondary measurements.

Applications of current transducers

The current transducer is used in many fields:

- power engineering and electricity distribution,

- industrial automation systems,

- monitoring the operation of motors and machines,

- photovoltaic and battery installations,

- protection against overloads and short circuits.

In each of these fields, the current measuring transducer acts as a reliable control element.

Summary

The current transducer and current transformer are basic measuring devices used in power engineering and automation. Their main task is to safely measure the primary current and convert it into a secondary signal that can be analyzed by a controller or measuring system. Both analog and digital transducers are available, including those with Modbus RTU interface.

The choice of the appropriate model depends on the type of current (AC or DC), measuring range, required accuracy, and application specifics. Thanks to transducers, it is possible to effectively monitor and protect electrical devices as well as optimize industrial processes.

We invite you to explore our offer and choose the right current transducer for your applications. Contact us to find the solution best suited to the needs of your system.

Related products

Related posts

Thermally conductive materials in power storages

Thermally conductive materials in power storages

Measuring power and energy in electric circuits

Measuring power and energy in electric circuits

Industrial communication in explosion hazardous areas (with MTL components)

Industrial communication in explosion hazardous areas (with MTL components)

Leave a comment