-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- TEMPEST emission revealing filters

- Surge arrester

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Spiralift Lifts

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Cable feedthroughs and couplers

- Litz wires

-

Cables for extreme applications

- Extension and Compensation cables

- Thermocouple cables

- Connection cables for PT sensors

- Multi-conductor wires (temp. -60C to +1400C)

- Medium voltage cables

- Ignition wires

- Heating cables

- Single conductor cables (temp. -60C to +450C)

- Railway cables

- Heating cables Ex

- Cables for the defense industry

- Go to the subcategory

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Steel Braids

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

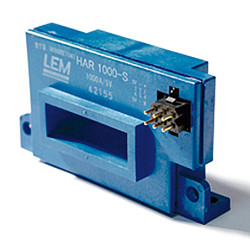

Transducer – principle of operation and examples of applications

A transducer is a measuring or electronic device whose task is to convert one form of energy, physical quantity, or signal into another. In practice, this means transforming, for example, pressure, temperature, light, humidity, or sound into an electrical signal that can be easily measured, analyzed, and transmitted in automation systems.

Thanks to transducers, it is possible not only to accurately measure industrial process parameters but also to monitor and control them. In electronic devices, they play a key role in converting analog and digital signals.

Principle of operation

The basic principle of a transducer’s operation is that the input signal, i.e., the measured physical quantity, is converted into a standardized output signal – analog or digital. Depending on the type of transducer, this process can occur through mechanical, piezoelectric, capacitive, or electromagnetic phenomena.

For example:

- a pressure transducer converts pressure value into an electrical signal,

- a temperature transducer converts temperature changes into voltage or current,

- an analog-to-digital converter (ADC) converts a continuous analog signal into a digital signal understandable to microprocessor systems.

Types of transducers

Depending on their purpose and output signal, there are various types of transducers. The most important include:

- Measuring transducers – used to convert physical values (e.g., pressure, temperature, humidity) into an electrical signal.

- Analog-to-digital converters (ADC) – convert analog signals into digital ones.

- Digital-to-analog converters (DAC) – the reverse of ADCs, converting digital signals into analog form.

- Piezoelectric transducers – use the piezoelectric effect to measure vibrations and acoustic pressure.

- Mechanical and capacitive transducers – used, among others, in measuring force, pressure, or acceleration.

Each of these types is used in different fields of engineering and industry.

Pressure transducer

One of the most commonly used devices is the pressure transducer. It is used to measure the pressure of liquids and gases in process installations. A change in pressure causes deformation of the measuring element, which is then converted into an electrical signal proportional to the measured value.

Applications of pressure transducers include:

- hydraulic systems,

- compressed air installations,

- chemical and energy processes,

- HVAC systems,

- monitoring water and technical gas pressure.

They make it possible to maintain the proper level of safety and optimize device performance.

Temperature transducer

Another example is the temperature transducer, which works with temperature sensors such as thermocouples or resistance sensors (e.g., PT100). Its task is to convert the signal from the sensor into a standardized current or voltage signal, often with galvanic isolation.

It is used in:

- temperature measurement in industrial processes,

- heating and air conditioning systems,

- production lines,

- laboratory equipment.

Thanks to signal standardization (e.g., 4…20 mA), it is possible to easily transmit information over long distances with high resistance to electromagnetic interference.

Analog-to-digital converter

In electronics, a particularly important role is played by the analog-to-digital converter. Its operation is based on sampling an analog signal and converting it into a digital form that can be stored, processed, and analyzed in microprocessor systems.

Key parameters for ADCs include:

- sampling frequency,

- resolution,

- dynamic range,

- noise immunity.

Without this type of transducer, the operation of audio devices, data recorders, measurement systems, or industrial automation would not be possible.

Digital-to-analog converter

The opposite of the ADC is the digital-to-analog converter (DAC), which converts digital data into an analog signal. It is used, among others, in audio systems, control of analog actuators, and testing of electronic circuits.

Applications of transducers – where can we find them?

Transducers have a wide range of applications – from consumer electronics to heavy industry. They are most commonly found in:

- industrial automation – monitoring technological process parameters,

- energy sector – measuring voltage, current, and power,

- HVAC systems – controlling pressure, temperature, and humidity,

- electronic devices – audio, telecommunications, measuring equipment,

- safety systems – detecting gases, pressure, or critical temperatures,

- laboratories – precise measurement of physical quantities using measuring transducers.

How to choose the right transducer?

The selection of an appropriate transducer depends on many factors:

- type of measured quantity (pressure, temperature, current, humidity),

- required measurement accuracy,

- type of output signal (analog, digital, current, voltage),

- operating conditions (ambient temperature, interference, industrial environment),

- integration with control systems (PLC, SCADA, monitoring systems).

In many cases, it is also crucial to ensure galvanic isolation and noise immunity, especially in industrial facilities.

Transducers in measurement and automation systems

In modern measurement systems, transducers play a central role. They connect sensors that record physical quantities with control and data recording systems. Thanks to them, the sensor signal is standardized and can be easily interpreted by PLC controllers, microprocessors, or computer systems.

In industrial automation, transducers ensure the reliability and stability of measurements, which translates into safety and efficiency of technological processes.

Summary

A transducer is a key element of modern technology that enables the conversion of various physical quantities into electrical signals that are easy to analyze and transmit. There are many types of transducers – from pressure and temperature to analog-to-digital and digital-to-analog converters.

Their principle of operation is based on converting the input signal into an output signal, and their applications cannot be overestimated – they are found in automation, energy, consumer electronics, and industrial systems.

We invite you to explore our offer and choose the right transducer for your applications. Contact us to find a solution perfectly suited to your needs.

Related products

Related posts

Thermally conductive materials in power storages

Thermally conductive materials in power storages

Measuring power and energy in electric circuits

Measuring power and energy in electric circuits

Wentylatory przemysłowe - rodzaje, właściwości

Wentylatory przemysłowe - rodzaje, właściwości

Leave a comment