Category

Photos are for informational purposes only. View product specification

please use latin characters

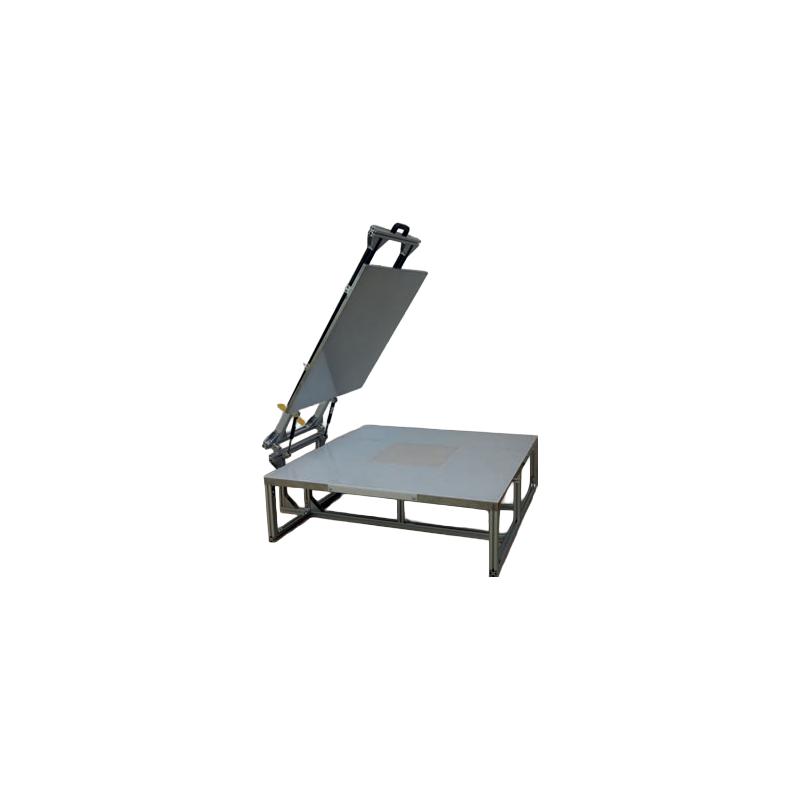

Test stands are used in plants producing electrically insulating runners and runners, and by their users, to perform periodic inspections and to diagnose equipment for energized work.

• The SC-40 stand is designed to perform voltage tests of runners in accordance with the requirements of the PN-IEC 61111 standard.

• Replaceable electrodes (standard 400 x 400, 600 x 600, 750 x 750 and corresponding covers) enabling testing of galleries with dimensions of 600x600 mm, 750x750 mm and over 1000 mm

• Other electrode dimensions possible

SC40

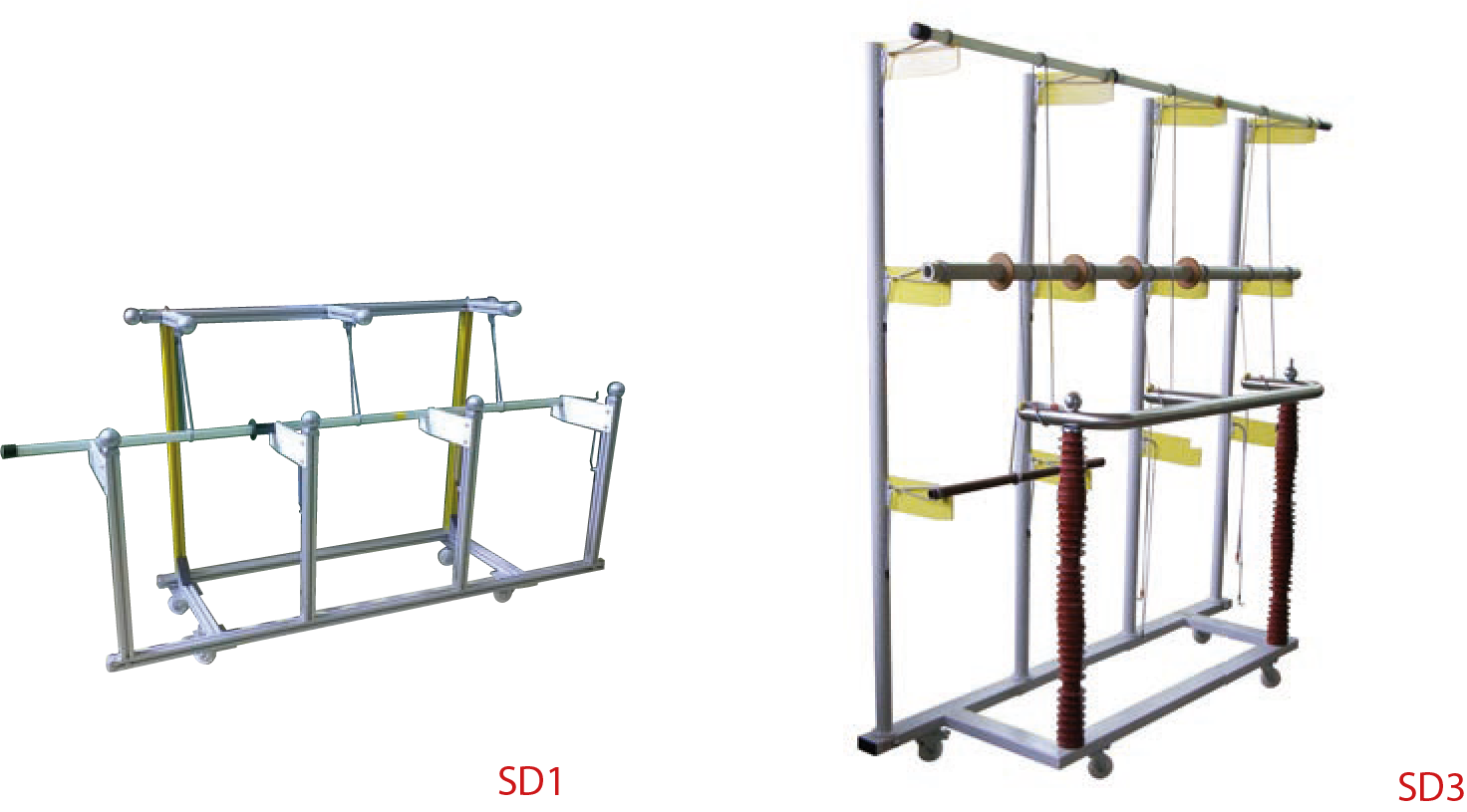

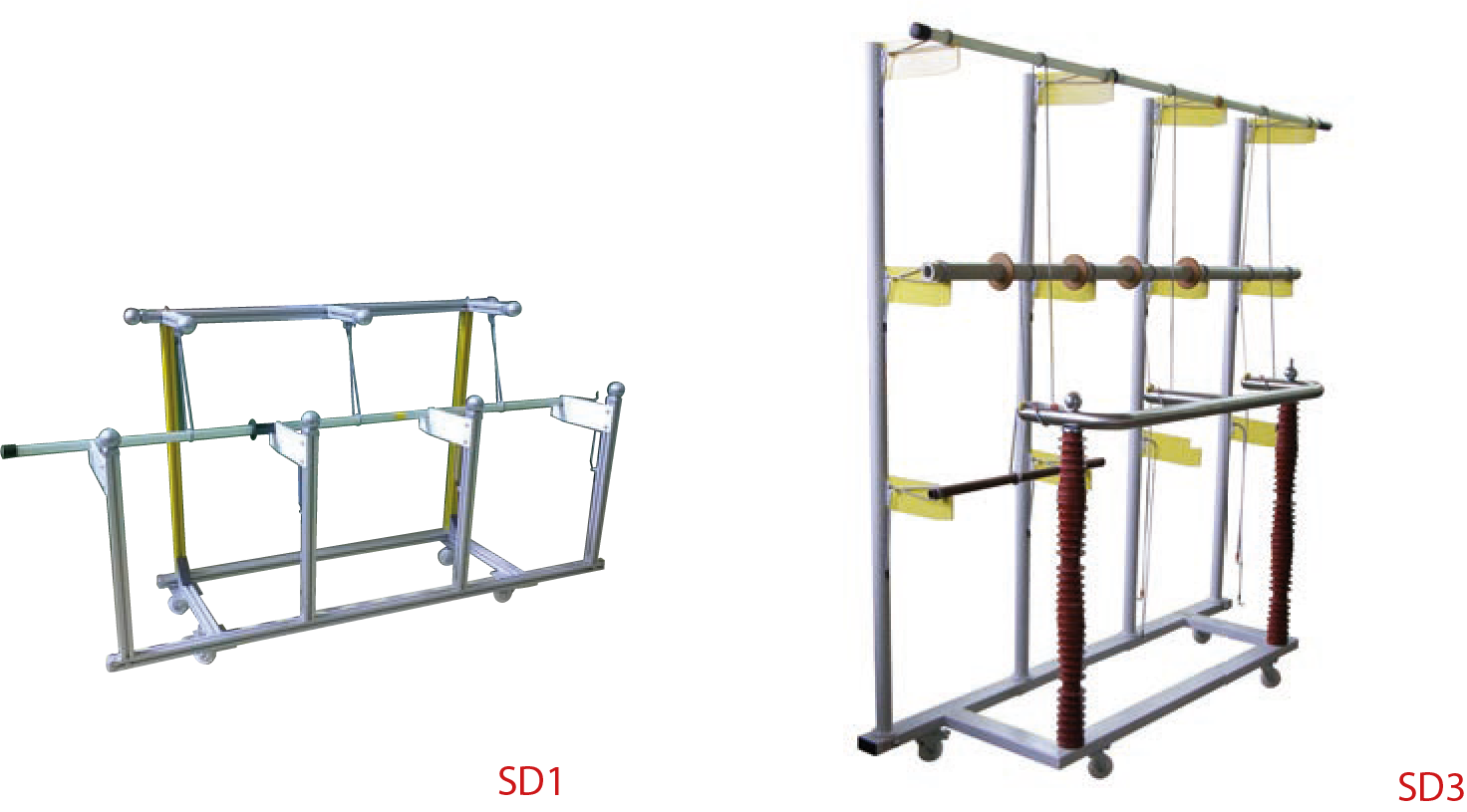

SC40• The SD1 and SD3 stations are designed to perform voltage tests of insulating sticks in accordance with requirements of the PN EN 60832 standard for 1 and 3

sticks, respectively.

• Testing of insulating sticks with a voltage of 100 kV (for every 300 mm of stick length)

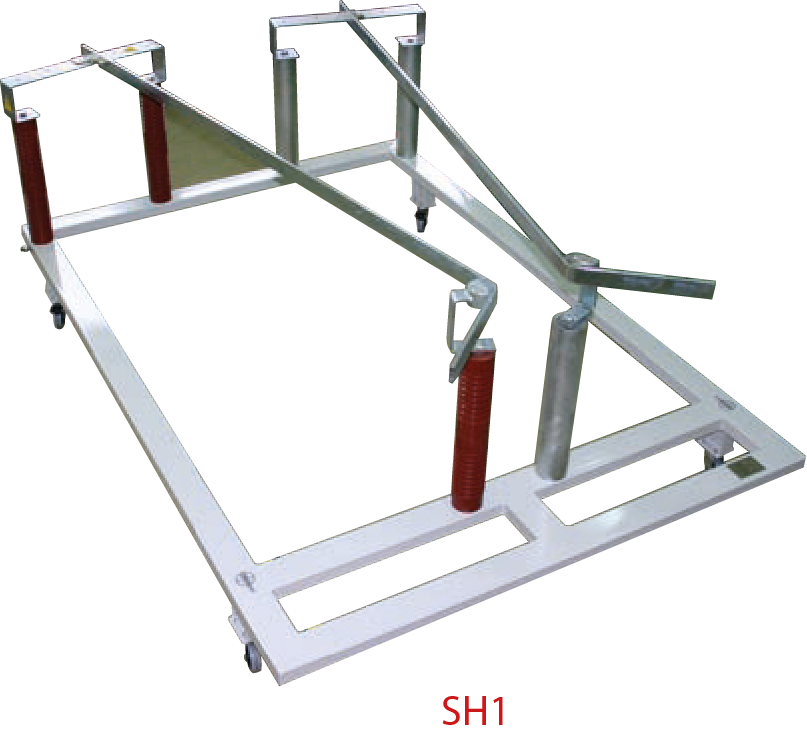

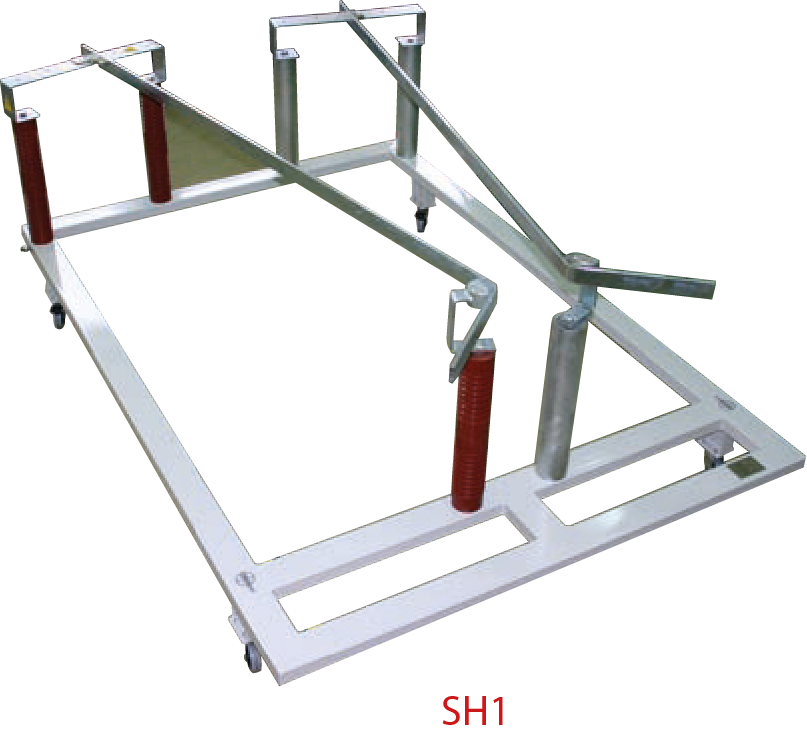

• The SH1 test stand is designed to test resistance to spark discharges and protection against bridging of equipment for live work up to 36 kV, as well as indicators and Voltage comparators

• Testing of working elements of various lengths in accordance with the manufacturer's guidelines for the tested equipment.

| Type | SC-40 | SD-1 | SD-3 | SH1 |

|---|---|---|---|---|

| Voltage Testing of high voltage circuit insulation | 48 kV | 120 kV | 120 kV | – |

| Operating voltage of tested tools | – | – | – | 36 kV |

| Test voltage | up to 40 kV | 100 kV | 100 kV | 43.2 kV |

| Test voltage system | 48 kV | 120 kV | 120 kV | 52 kV |

| Dimensions of tested walkways | 600x600, 750x750, over 1000 mm (class 2) |

– | – | |

| Length of tested rod in one test | – | max. 1800 mm | max. 1800 mm | – |

| Weight [kg] | 65 kg | 25 kg | 35 kg | 90 kg |

| Environmental operating conditions: | ||||

| – temperature | 5÷30°C | |||

| – relative humidity | <80% (without condensation) water) | |||

| – atmospheric pressure | 80÷106 kPa | |||

| – protection class | IP 00 | IP 00 | IP 40 | |

• Meets the requirements of current PN-EN standards

• Ergonomic design facilitates correct testing

• Production process parameters compliant with the Quality Management System according to PN-EN ISO 9001:2009.

Are you interested in this product? Do you need additional information or individual pricing?

Test stands are used in plants producing electrically insulating runners and runners, and by their users, to perform periodic inspections and to diagnose equipment for energized work.

• The SC-40 stand is designed to perform voltage tests of runners in accordance with the requirements of the PN-IEC 61111 standard.

• Replaceable electrodes (standard 400 x 400, 600 x 600, 750 x 750 and corresponding covers) enabling testing of galleries with dimensions of 600x600 mm, 750x750 mm and over 1000 mm

• Other electrode dimensions possible

SC40

SC40• The SD1 and SD3 stations are designed to perform voltage tests of insulating sticks in accordance with requirements of the PN EN 60832 standard for 1 and 3

sticks, respectively.

• Testing of insulating sticks with a voltage of 100 kV (for every 300 mm of stick length)

• The SH1 test stand is designed to test resistance to spark discharges and protection against bridging of equipment for live work up to 36 kV, as well as indicators and Voltage comparators

• Testing of working elements of various lengths in accordance with the manufacturer's guidelines for the tested equipment.

| Type | SC-40 | SD-1 | SD-3 | SH1 |

|---|---|---|---|---|

| Voltage Testing of high voltage circuit insulation | 48 kV | 120 kV | 120 kV | – |

| Operating voltage of tested tools | – | – | – | 36 kV |

| Test voltage | up to 40 kV | 100 kV | 100 kV | 43.2 kV |

| Test voltage system | 48 kV | 120 kV | 120 kV | 52 kV |

| Dimensions of tested walkways | 600x600, 750x750, over 1000 mm (class 2) |

– | – | |

| Length of tested rod in one test | – | max. 1800 mm | max. 1800 mm | – |

| Weight [kg] | 65 kg | 25 kg | 35 kg | 90 kg |

| Environmental operating conditions: | ||||

| – temperature | 5÷30°C | |||

| – relative humidity | <80% (without condensation) water) | |||

| – atmospheric pressure | 80÷106 kPa | |||

| – protection class | IP 00 | IP 00 | IP 40 | |

• Meets the requirements of current PN-EN standards

• Ergonomic design facilitates correct testing

• Production process parameters compliant with the Quality Management System according to PN-EN ISO 9001:2009.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent