-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- TEMPEST emission revealing filters

- Surge arrester

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Spiralift Lifts

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Cable feedthroughs and couplers

- Litz wires

-

Cables for extreme applications

- Extension and Compensation cables

- Thermocouple cables

- Connection cables for PT sensors

- Multi-conductor wires (temp. -60C to +1400C)

- Medium voltage cables

- Ignition wires

- Heating cables

- Single conductor cables (temp. -60C to +450C)

- Railway cables

- Heating cables Ex

- Cables for the defense industry

- Go to the subcategory

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Steel Braids

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

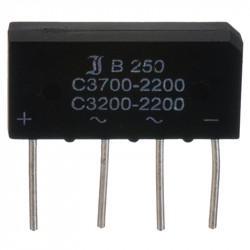

Bridge Rectifiers – Principle of Operation and Industrial Applications

Modern electronics and energy systems rely heavily on stable direct voltage (DC), which is essential for the proper operation of electronic circuits and power systems. Bridge rectifiers are key components that allow the conversion of alternating current (AC) into direct current (DC). Thanks to them, it is possible to power electronic devices, controllers, automation systems, as well as industrial power systems.

A bridge rectifier, also known as a rectifier, operates by polarizing the diodes in reverse bias and allowing conduction in forward bias, enabling the conversion of mains voltage into stable direct current. It is used both in simple household circuits and in large industrial systems where high efficiency and reliability are required.

Construction of a bridge rectifier

The construction of a bridge rectifier is based on a simple yet effective arrangement of four rectifier diodes. Each diode conducts current in only one direction, enabling the rectification of alternating voltage. In the classic version, the so-called Graetz bridge, the diodes are connected in such a way that, regardless of the polarity of the input voltage, a nearly constant direct voltage is produced at the output. In practice, this voltage is pulsating (rippled) and requires the use of filter capacitors or other smoothing circuits. In three-phase bridge rectifiers, the system may use 6 diodes instead of 4, which allows rectifying current in industrial systems and machinery.

An important parameter of a bridge rectifier is the maximum forward current and reverse voltage, which determine the device’s ability to operate under given conditions. Bridge rectifiers come in various versions: from small single-phase rectifiers to high-power systems used in industrial energy applications.

The construction of a bridge rectifier may also include auxiliary components such as filter capacitors, which smooth the output voltage and increase the stability of the DC current. In practice, correct diode connection and the choice of appropriate rectifier parameters are crucial for the reliability of the entire system.

Operating principle of a bridge rectifier

A bridge rectifier works by directing current through diodes. During the first half-cycle of the alternating current, two diodes conduct while the other two remain reverse-biased. During the second half-cycle, the roles of the diodes switch. As a result, the output current is pulsating (rippled), and the voltage requires further filtering and stabilization. Additionally, each diode introduces a voltage drop of about 0.7 V (for silicon diodes), which must be considered when designing low-voltage circuits.

Thanks to this operating principle, a bridge rectifier converts alternating voltage into direct voltage, which can be used to power electronic devices, power supplies, controllers, or industrial applications. The use of a bridge rectifier ensures proper functioning of systems requiring a stable output voltage, such as voltage stabilizers or automation systems.

Types of bridge rectifiers

Various types of bridge rectifiers are available on the market depending on the needs and parameters of the application:

- Single-phase bridge – a simple solution for small electronic devices and household power supplies.

- Three-phase bridge – used in industrial systems, machinery, and energy devices requiring higher power levels.

- High-current bridge rectifiers – for applications in power engineering, industrial processes, or large power supplies, capable of conducting currents up to hundreds of amperes.

- Miniature SMD bridges – intended only for low-power electronic circuits with compact dimensions; not suitable for high-current industrial applications.

Selecting the right bridge rectifier requires considering the maximum forward current, diode reverse voltage, and the application requirements. A properly selected bridge rectifier ensures stable output voltage and minimizes the risk of overheating or damage to electronic systems.

Industrial applications of bridge rectifiers

Bridge rectifiers are used in many industrial areas, from simple control devices to advanced power systems. The most common applications include:

- Industrial power supplies – converting AC to DC in stabilizers and UPS systems.

- Battery chargers and accumulator systems – rectifying current for charging batteries in electric vehicles or energy storage systems.

- Automation and control systems – providing stable power to controllers, relays, and other electronic components.

- Industrial energy systems – rectifying voltage in transformers and high-voltage energy networks.

- Electronic devices – ensuring unidirectional current flow in microprocessor systems, machines, and control systems.

In each of these cases, the bridge rectifier plays a key role in ensuring reliable operation, protecting electronic components, and maintaining stable output voltage.

Best practices for selecting a bridge rectifier

When designing systems with bridge rectifiers, it is worth considering several critical aspects:

- Maximum forward current selection – must match the current drawn by the system.

- Diode reverse voltage selection – to avoid diode breakdown during operation.

- Cooling and housing – larger high-current bridges require proper heat sinks or forced ventilation to avoid overheating and diode damage.

- Output filtering – the use of filter capacitors improves voltage stability.

- Bridge rectifier inspection – regular monitoring of diode parameters and condition increases system lifespan.

Following these principles improves system efficiency, minimizes the risk of failures, and ensures stable output voltage for all devices connected to the system.

Bridge rectifiers in practice

In practice, bridge rectifiers are ubiquitous in electrical and industrial systems. Every device powered by direct current uses a rectifier, even if it is a small charger or a computer power supply. In larger industrial applications, such as motor controllers, automation systems, or energy storage, bridge rectifiers play a crucial role in maintaining system stability and reliability.

It is also important to remember that bridge rectifier failures can lead to overheating, overvoltage, and damage to the entire system. Therefore, selecting the appropriate bridge rectifier, checking its parameters, and ensuring proper cooling are fundamental to designing reliable power systems.

Summary

Bridge rectifiers are indispensable elements in electronics and industry that convert alternating current into direct current. Their proper construction and operating principle ensure stable output voltage, reliability, and protection of electronic components. They are used in both simple power supplies and advanced industrial automation and energy systems.

We invite you to explore our offer – we provide a wide range of bridge rectifiers ideal for industrial and electronic applications. Discover how our solutions can increase the reliability and efficiency of your systems.

Related products

Related posts

Thermally conductive materials in power storages

Thermally conductive materials in power storages

Measuring power and energy in electric circuits

Measuring power and energy in electric circuits

Wentylatory przemysłowe - rodzaje, właściwości

Wentylatory przemysłowe - rodzaje, właściwości

Leave a comment